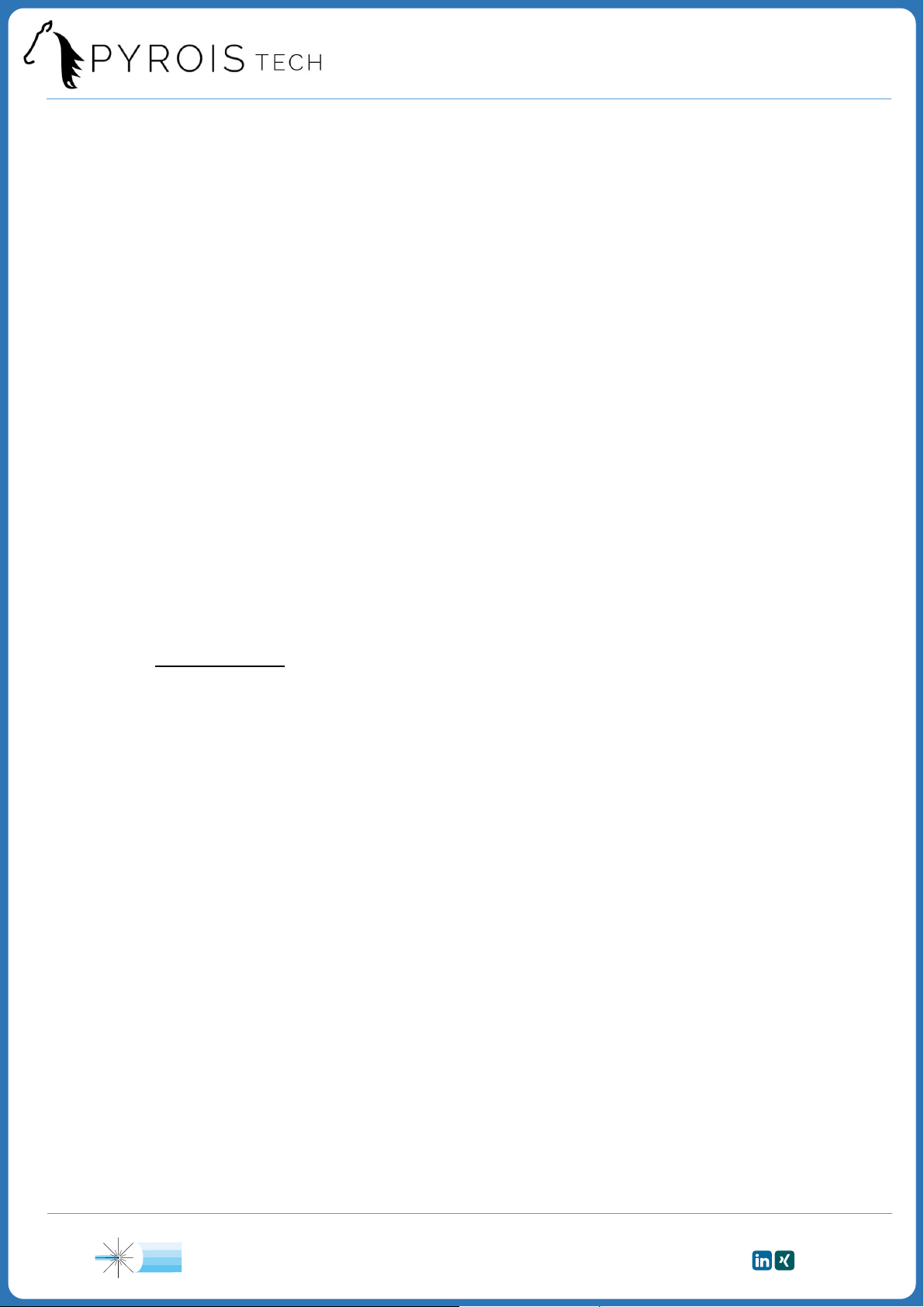

10

1SLED information

2SLED ON/OFF button

3

OUT

4

5

6

view button

7

arrow

Figure 2. SLED screen

1

3

4

2

5

6

7

SLED information (1)

On the left of the screen, the following information can be read:

•Name of the SLED

•Central wavelength of the SLED

•Full width at half maximum (FWHM)

Control of the output power

On the right of the screen, the percentage of the nominal output power of the SLED

can be adjusted from 0% to 100% with the following controls:

•SLED ON/OFF button (2):

–This button is OFF (grey) if the percentage is equal to 0%. By pressing it, it will

change to the ON state (light green) and the output power will be set to 100%.

–This button is ON (light green) if the percentage is higher than 0%. By pressing it, it

will change to the OFF state (grey) and the output power will be set to 0%.

•SLED Temperature (ºC)

•SLED Current (mA)

•Type of error (only when an error has

occurred, see Figure 5 on next page)

•Keypad (3): by clicking on the number, a keypad will

appear (Figure 3). A percentage 0%-100% can be

introduced by using it. You can erase a digit by pressing

‘DEL’. Press ‘OK’ to confirm the percentage. If the value

introduced is higher than 100%, it will be replaced by

the previous valid percentage.

•Arrows (4): using the up/down arrows will increase/decrease the current percentage

of the nominal output power by 1%.

•Slide bar (5): it permits you to adjust the output power from 0% to 100%. While

dragging the slide bar, it will be in yellow, and it will change to green once a value has

been selected.

On the bottom of the screen, if we click on “Spectrum view” (6), we will see the spectral

power distribution of the corresponding SLED (see Figure 4 on next page). The arrow (7)

enables to return to the initial screen.

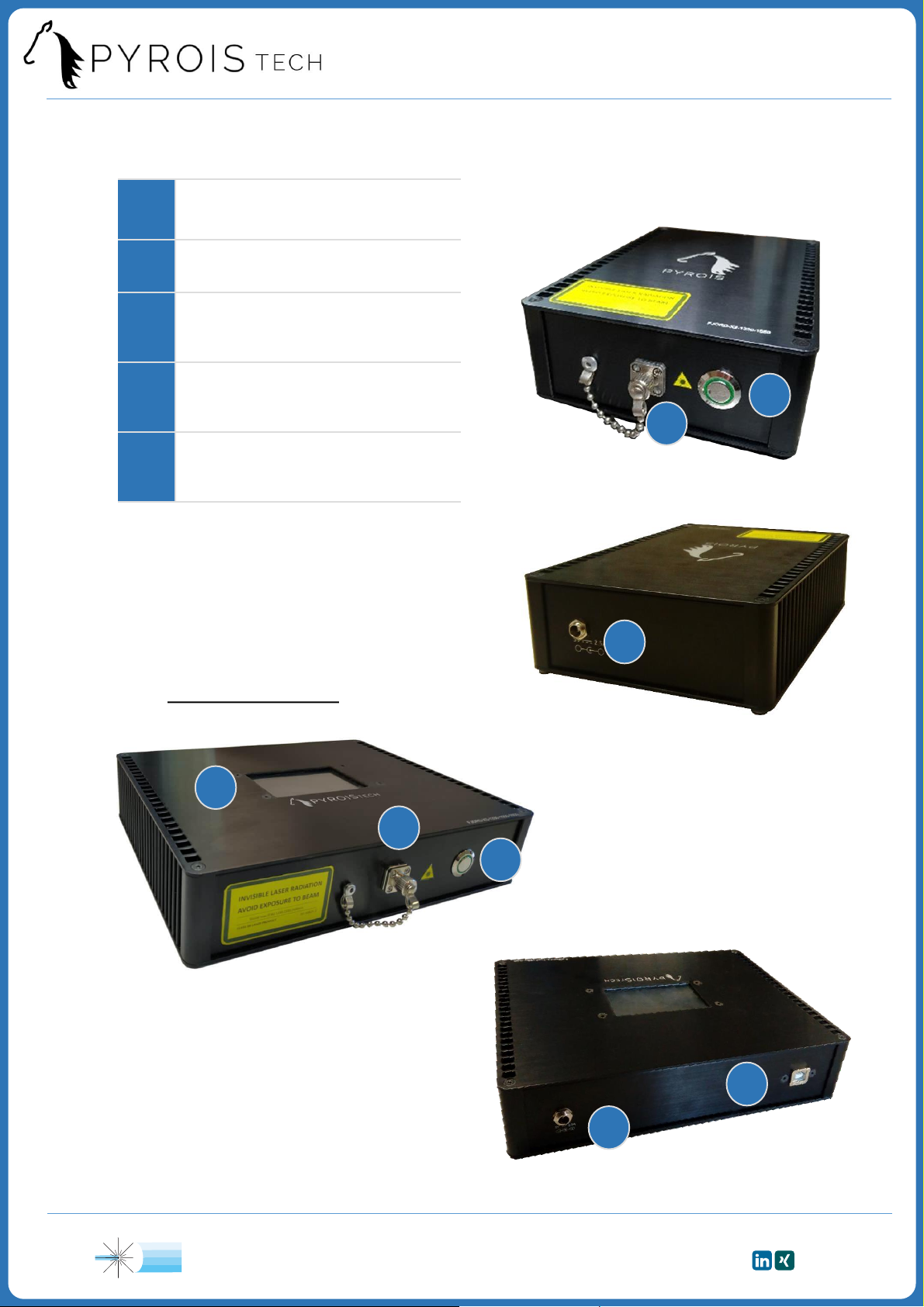

Figure 3. Keypad

2.5.2 SLED screen

The sequence ‘70925841’written on the keypad will restore

all the source parameters to their Factory Mode values

SI Scientific Instruments GmbH

Roemerstr

.

67

|

82205

Gilching

+49 8105 77940 | [email protected] | www.si-gmbh.de | Follow us on:SI