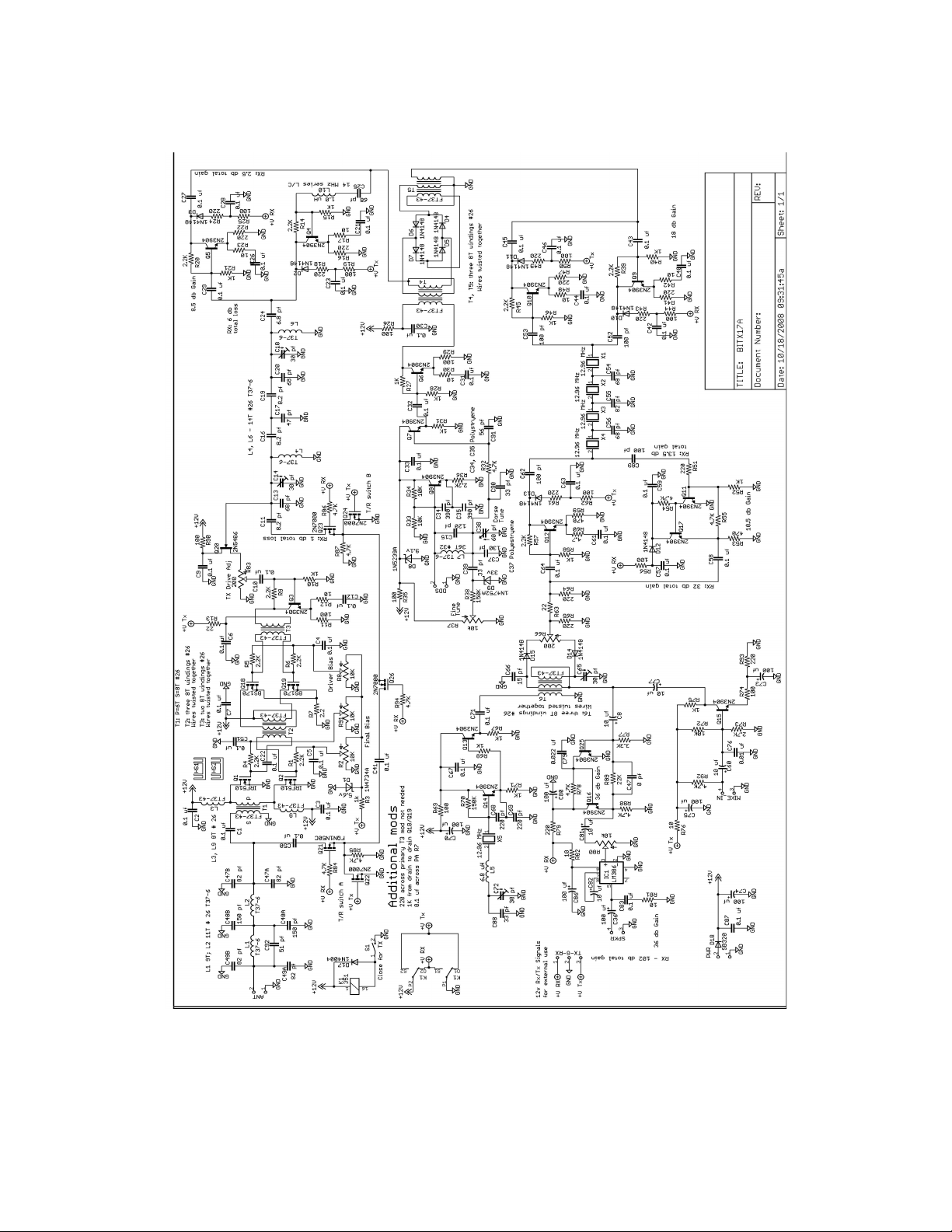

Congratulations. You have completed converting your BITX20A to a BITX17A, and are ready to

proceed with alignment of the transceiver, including transmitter driver stages and the MOSFET power

amplifiers.

Now might be a good time to check R-2. R-8, R-83, and R-91 to insure that they are turned

totally counter-clockwise. This is to make sure that the transmitter RF drive level is at

minimum, and that the MOSFET bias levels are also at minimum. During the alignment

procedure you will set these potentiometers at their proper levels.

To proceed with transceiver alignment you will need the following tools:

●50 ohm Dummy load. This can be an actual dummy load, or a bank of non-inductive resistors

which will withstand 12 watts or more for up to one minute.

●An Oscilloscope, or Diode Voltage Probe and Voltmeter for measuring RF voltage levels at 18

MHz.

●A DC Ampere Meter capable of measuring 0 to 300 ma, and 0 to 2 amperes. There is an

alternative way to measure the 0 to 300 ma levels using voltage across a resistor. This will be

discussed in the alignment procedures.

●The Microphone that you are going to use with this transceiver, or an audio signal generator and

suitable attenuators to adjust it's output to normal microphone signal levels (nominally 40 to 50

millivolts).

●A Frequency Counter, or other means to determine VFO frequency and tuning range. A

receiver with accurate frequency readout may be suitable.

Initial Alignment Procedure:

These steps will get you on the air. A more detailed alignment method is documented in the

troubleshooting section.

1. Set the BFO and carrier oscillator frequency:

Adjust the BFO (C-72) so that when you tune across a steady carrier you can hear the zero-beat

on each side of that carrier frequency. Then adjust C-72 to a slightly lower frequency where you

can hear the upper-sideband zero-beat tone but the lower-sideband one is either gone or very

much attenuated. Now tune in an on-air SSB signal and adjust C-72 very slightly for best audio

quality.

2. Set the carrier balance:

STEP-1: With an detector probe or oscilloscope monitorin the 12.96 MHz si nal at

Page 10 of 34