Capacitors:

There are four types of capacitors used.

●

Multi-layer (MONO) caps, which are generally yellow and rectangular is shape.

●

NPO type disks will have a black dot on the top edge of the cap. Note. Some of the ceramic disk caps will have lead spacing wider

then the hole spacing on the board. In this case, use your needle nose pliers to kink both leads inward slightly to match the board

hole spacing.

●

Film capacitors. These will be green in color.

●

Aluminum Electrolytic. These are round cylinders and have polarity. They must be installed with the correct polarity. Electrolytic

caps inserted with the wrong polarity across the DC supply can heat up and explode! The negative lead is marked with a black

stripe and the positive lead is always the longer lead.

Capacitor value markings:

The capacitor value is marked on the part with a two or three digit number and is read in picofards. The third digit is the zero multiplier.

Values of less than 100 pfd generally show only two digits, but sometimes three. Therefore, if a part is marked 470, that means it is a 47 pfd

cap and not a 470 pfd cap. A 470 pfd cap would be marked 471. Mono caps also often have letters printed on the part. These letters

indicate the type or tolerance and can be disregarded.

NOTE: Although the electrolytic caps are listed in the table below, they should be installed last.

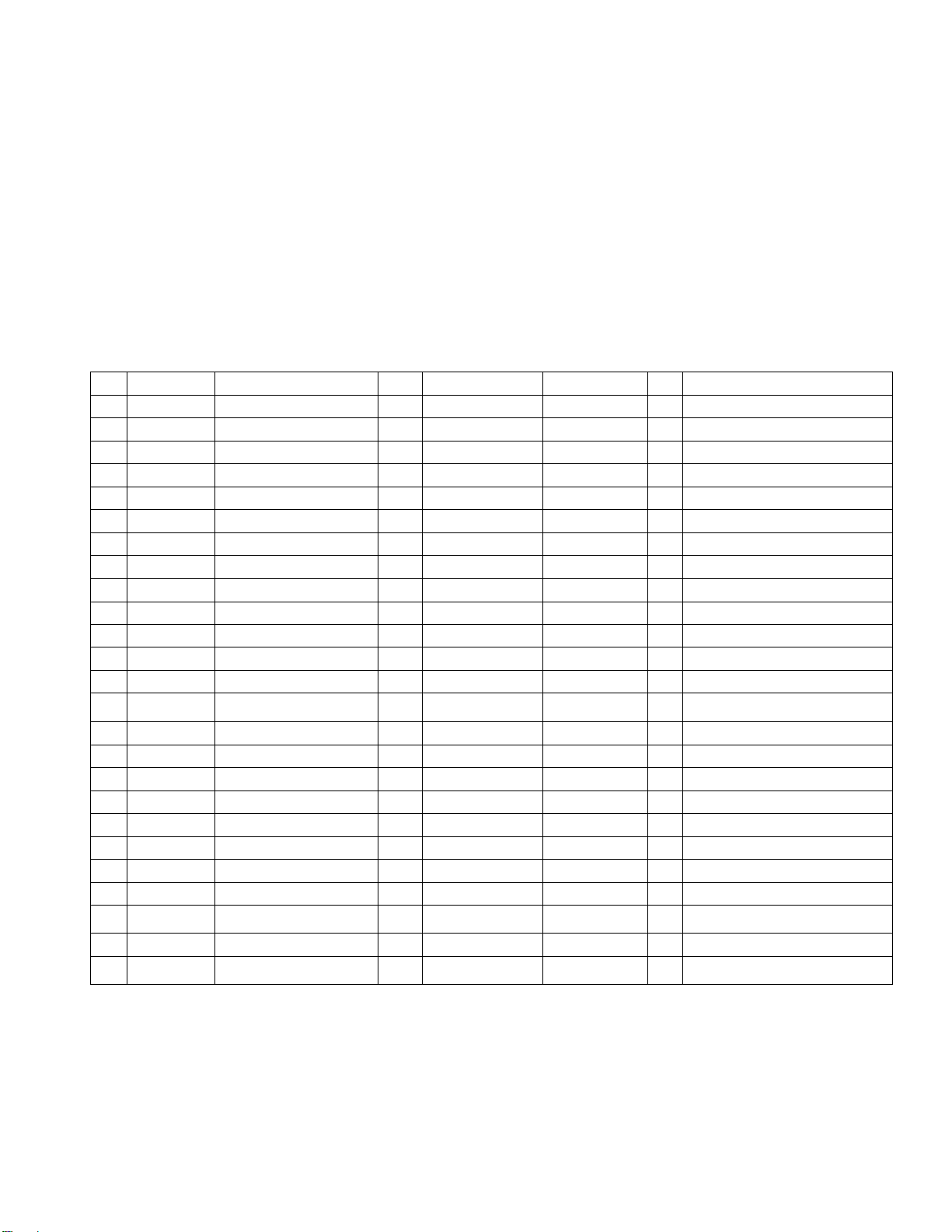

√location value type √location value type

C1 BAND SPEC SEE BAND TABLE

C23 0.1 ufd (104) MONO, YELLOW

C2 0.1 ufd (104) MONO, YELLOW

C24 100 pfd (101) NPO DISK, OR MONO YELLOW

C3 0.1 ufd (104) MONO, YELLOW

C25 2.2 pfd (2.2) NPO DISK, BROWN

C4 100 ufd /16 or 25V ELECTOLYTIC

C26 2.2 pfd (2.2) NPO DISK, BROWN

C5 100 ufd /16 or 25V ELECTOLYTIC

C27 0.1 ufd (104) MONO, YELLOW

C6 BAND SPEC SEE BAND TABLE

C28 22 pfd (22) NPO DISK, BROWN

C7 BAND SPEC SEE BAND TABLE

C29 47 pfd (47) NPO DISK, BROWN

C8 BAND SPEC SEE BAND TABLE

C30 22 pfd (22) NPO DISK, BROWN

C9 0.1 ufd (104) MONO, YELLOW

C31 0.1 ufd (104) MONO, YELLOW

C10 0.01 ufd (103) FILM, GREEN

C32 100 pfd (101) NPO DISK, OR MONO YELLOW

C11 BAND SPEC SEE BAND TABLE

C33 10 ufd /16 or 25V

ELECTROLYTIC

C12 BAND SPEC SEE BAND TABLE

C34 100 pfd (101) NPO DISK, BROWN

C13 BAND SPEC SEE BAND TABLE

C35 100 pfd (101) NPO DISK, OR MONO YELLOW

C14 0.1 ufd (104) MONO, YELLOW

C36 0.1 ufd (104) MONO, YELLOW

C15 0.1 ufd (104) MONO, YELLOW

C37 100 pfd (101) NPO DISK, OR MONO YELLOW

C16 BAND SPEC SEE BAND TABLE

C38 100 pfd (101) NPO DISK, OR MONO YELLOW

C17 0.1 ufd (104) MONO, YELLOW

C39 100 pfd (101) NPO DISK, OR MONO YELLOW

C18 22 pfd (22) DISK

C40 100 pfd (101) NPO DISK, OR MONO YELLOW

C19 BAND SPEC SEE BAND TABLE

C41 .1ufd SMT PREINSTALLED

C20 BAND SPEC SEE BAND TABLE

C42 .01 ufd SMT PREINSTALLED

C21 BAND SPEC SEE BAND TABLE

C43 .01 ufd SMT, PREINSTALLED

C22 BAND SPEC SEE BAND TABLE

C44 22 pfd SMT, PREINSTALLED

C45 .01 ufd SMT, PREINSTALLED

C58 0.1 ufd (104) MONO, YELLOW

C46 100 ufd/16 or 25V ELECTROLYTIC

C59 .001 ufd (102) DISK, BROWN