Models Q4P09H, Q4P09X & Q4P09W

Installation, Operation and Maintenance

10 Rev 12/26/13

Q4P09-IOM-Q.doc

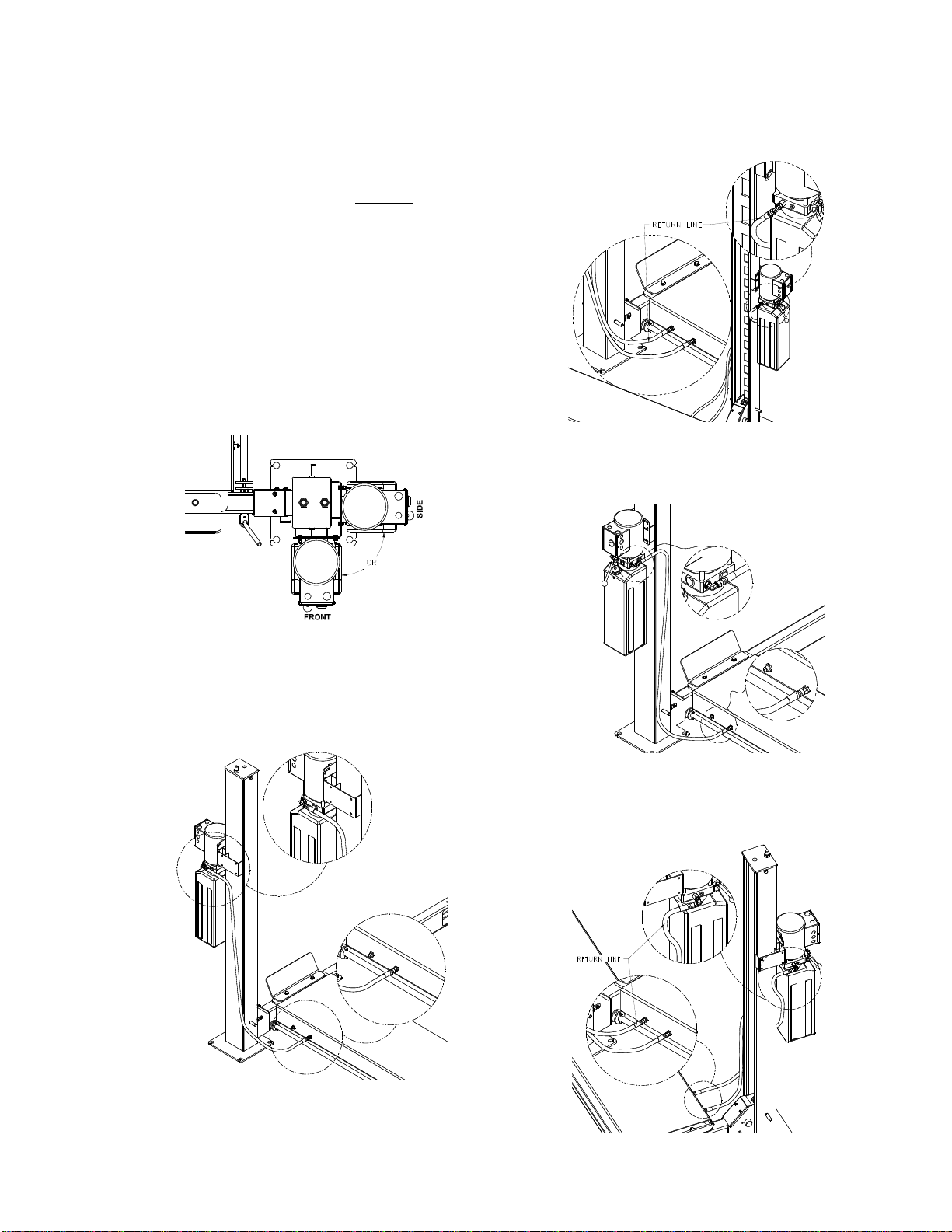

NOTE: When attaching the return line to the

bulk head i n the run way, make sure it is

securely attached at the power unit, and the

hose is not twisted or kinked into a position

that will lead to getting caught on the po wer

unit reservoir or the stud on the column

sides. Rais e the lift and carefully watch the

path the hose is riding u p the column, adjust

connection at the power unit and/or runway

bulkhead to allow the hose to move up

between the power unit and colum n. Make

sure the hose doesn’t catch on the column

caster lug as the lift rises.

38) Install O-Ring end of the straight hydraulic

fitting (9/16-18 O-Ring x M14x1.5-6g) to

power unit output port. Connect the

hydraulic hose to the hydraulic bulkhead

fitting in the power runway.

Do Not Use Teflon Tape or Pipe Dope on

fittings.

39) Connect the power unit to a suitable

electrical power source. The standard power

unit is 115 volt 50/60 Hz single phase

requiring a dedicated 15 amp single throw

circuit breaker to operate lift at full capacity.

40) BE CERTAIN ALL FITTINGS AND CONNECTIONS

ARE TIGHT. IT IS THE INSTALLERS

RESPONSIBILITY TO INSURE SYSTEM IS LEAK-

FREE. Fill the Power Unit with three gallons of

clean 10wt anti-foam anti-rust hydraulic oil or

Dexron III ATF. DO NOT USE OILS WITH

DETERGENTS.

41) Energize the power unit and raise the lift

approximately 1 ft off the ground and look

underneath the power runway to verify that

the cable lugs are resting firmly against the

cylinder pull bar.

42) To level the runways and crossbeams use a

4 ft. level. With the lift resting in its locks, find

the highest corner and adjust the other three

column ladder bars until the runways are

level front-to-rear and side-to-side. Tighten

jam nut against bottom side of each column

top plate.

43) Adjust cables until all four locks are

synchronized when lift is raised. Tighten

cable jam nuts against adjustment nuts.

44) Raise and lower lift several times to bleed

hydraulic cylinder. Hydraulic cylinder is self

bleeding. Lower lift and check fluid level in

reservoir. Add fluid as needed.

45) Run lift to full rise and continue running motor

approximately 5 more seconds. Check

hydraulic hose and connections for leaks.

Re-tighten fitting if leaking.

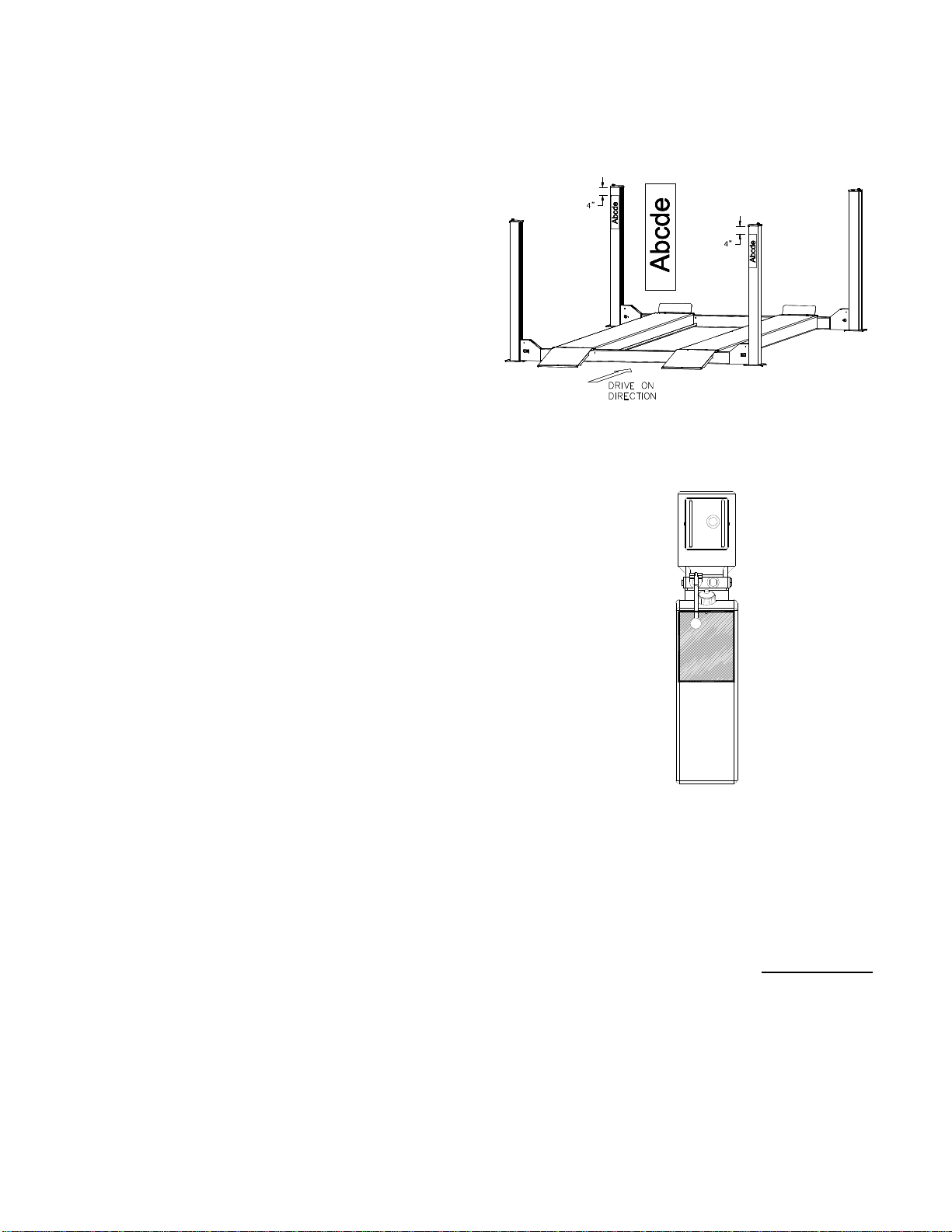

COLUMN DECAL PLACEMENT

46) Center the decal on the front drivers side

column and rear passenger side column.

47) Apply decal 4” from top of columns, Fig 22.

Fig 22 – Decal Placement

48) Place the Caution, Warning and Safety

Instructions decals seen on page 4, on the

power unit as shown, Fig 223.

Fig 23 – Power Unit Decal

OWNER/OPERATOR CHECKLIST

SAVE THESE INSTRUCTIONS deliver them to

owner/user/employee along with other materials

furnished with this lift.

49) Demonstrate the operation of the lift to the

owner/operator and review correct and safe

lifting procedures using the Lifting It Right

booklet as a guide.

50) Complete the Installation Checklist/Warranty

Validation questionnaire with the owner.

Review the terms of the warranty registration

card, and return the card and a copy for the

questionnaires to:

Quality Lifts, Inc.

P.O. Box 3944

Louisville, KY. 40206