General Safety Notes and Driving Limits

WARNINGS!

The construction of this wheelchair, as well as the

technology used, are designed to give the maximum level

of safety. International safety standards currently in force

have either been fulfilled or exceeded in parts.

Nevertheless, users may put themselves at risk by

improperly using their wheelchairs. For your own safety,

the following rules must be observed.

Unprofessional or erroneous changes or adjustments

increase the risk of accident. As a wheelchair user, you

are also part of the daily traffic on streets and pavements,

just like anyone else. We would like to remind you that

you must comply with any relevant traffic laws and

pedestrian restrictions.

Be careful during your first ride in this wheelchair. Get to

know your wheelchair.

Before each use, the following should be checked:

• Quick-release axles on the rear wheels

• Velcro on seats and backrests

• Tyres, tyre pressure, and wheel locks.

Before changing any of the adjustments of this

wheelchair, it is important to read the

corresponding section of the Owner’s manual.

WARNINGS!

Maximum weight limit: 125 kg. Please note the•

weight information for lighter weight options,

which are quoted separately.

This wheelchair should be used exclusively to convey •

one person at a time. Any other use does not comply

with the intended purpose.

Your wheelchair has not been designed for •

transportation in a vehicle. DO NOT sit on the

wheelchair during any transportation in a vehicle;

always use a properly secured vehicle seat!!

Your wheelchair is not designed to be a seat during •

transportation.

Only permanently installed seats and safety belts will •

offer sufficient protection in hazardous situations.

When vehicles are in motion, unoccupied wheelchairs •

should be secured using appropriate means.

Before changing any of the adjustments of this •

wheelchair, it is important to read the corresponding

section of the Owner’s manual.

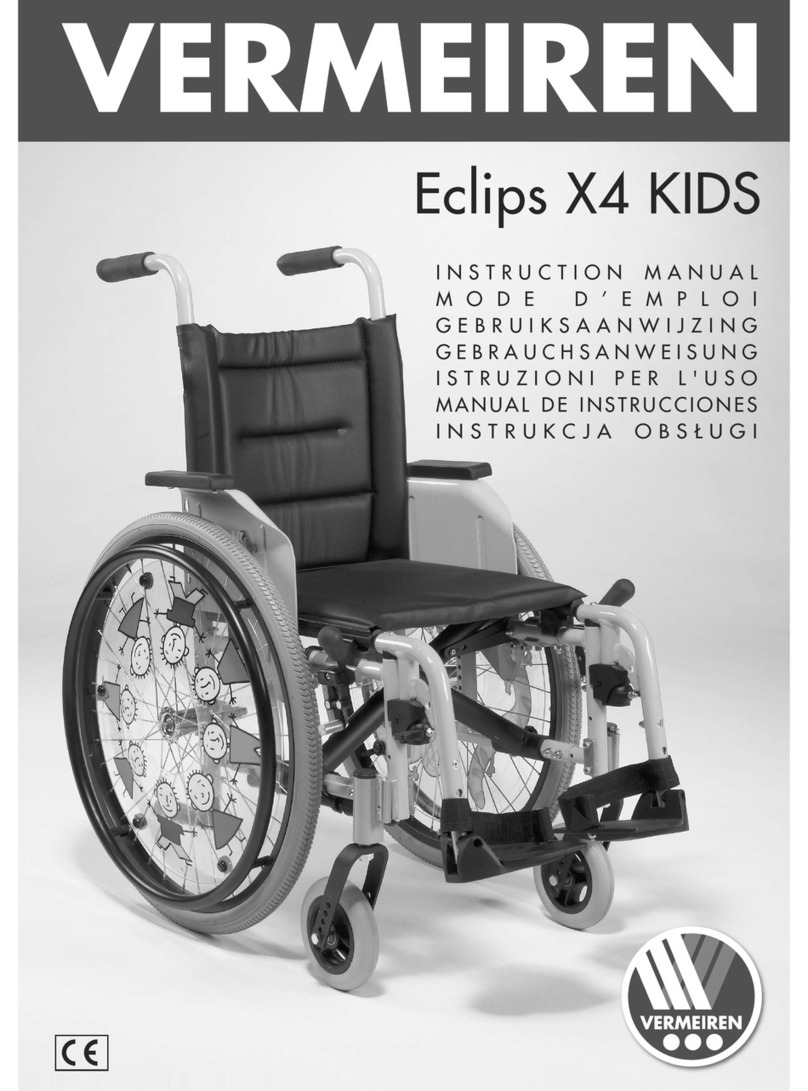

It is possible that potholes or uneven ground could •

cause this wheelchair to tip over, especially when

riding uphill or downhill (Fig. A).

When riding over a step or up an incline frontally, the •

body should be leaning forward, (Fig. A).

DANGER!

Secure your wheelchair on uneven ground or when •

transferring (e. g. into a car) by using the brakes.

For thigh amputees you must position the rear wheels •

towards the back and/or use anti-tip tubes.

With active centre of gravity adjustment, the •

wheelchair may tip over, so anti-tip tubes should be

used.

This product has been tested to a maximum speed of •

10kph. At higher speeds, depending on the

configuration and/or physique/physical capabilities of

the user, there may be unexpected castor wobble.

This can lead to injury of the user.

Before setting off, check that your tyre pressure is •

correct. The correct tyre pressure is printed on the

edge of the wheel, for rear wheels it should be at

least 3.5 bar (350 kPa).

All brakes will only work if there is sufficient tyre •

pressure and if the correct setting has been made

(see the Chapter on "Brakes").

Fig. A