3

INTRODUCTION

* The economy setting reduces the water flow to give economical use of water, whilst

still giving an adequate shower performance.This setting performs best with most

gravity, pumped, and mains pressure unvented systems. On electric showers and

some combination boiler systems the economy setting will have no effect, and will

give the same spray action as the start setting.

**The security hose retaining ring for use with Category 5 risk installations is

permanently connected to the hose. It allows the hose to move through it for

showering, but complete withdrawal of the hose is prevented.

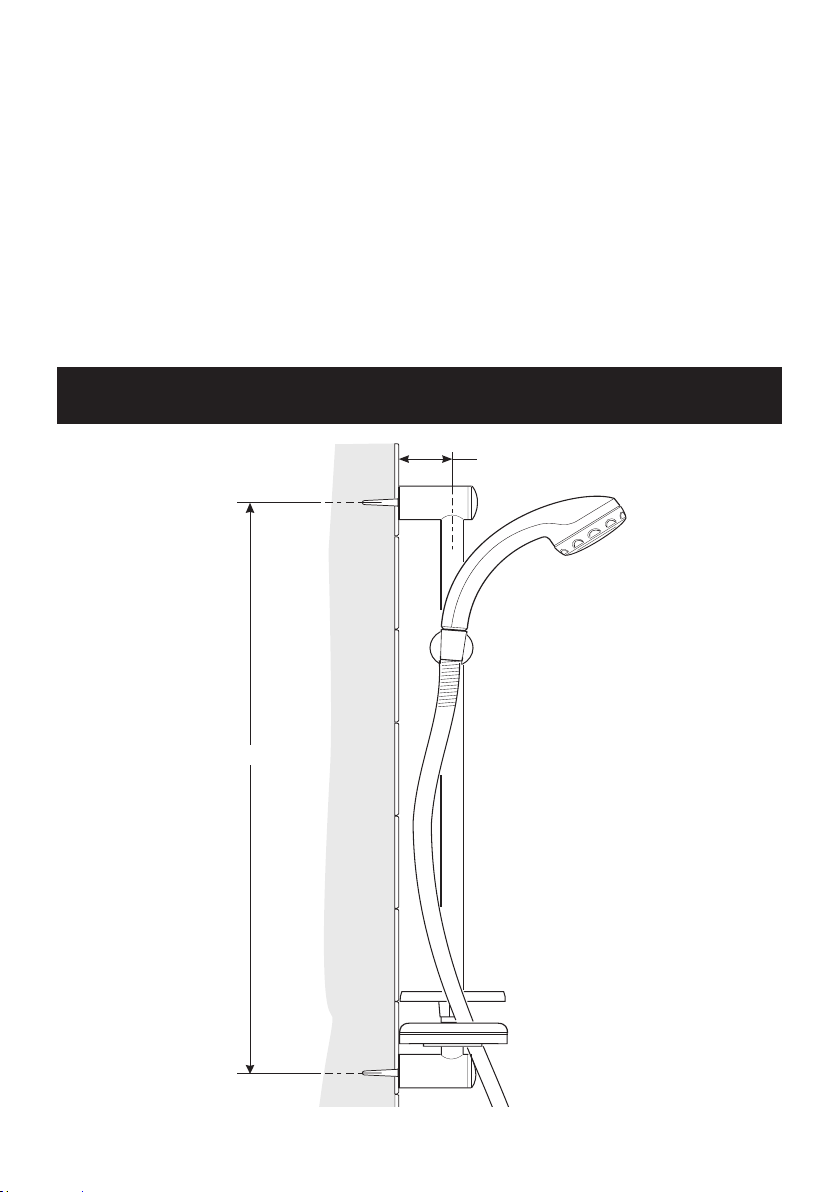

Thank you for purchasing a quality Rada product. To enjoy the full potential of your

new product, please take time to read this guide thoroughly, having done so, keep

it handy for future reference. The following shower fittings are covered by this guide:

Rada Autotherm-3 EV Shower Fitting

An adjustable spray handset with three different spray actions (start, force, soothe),

and an economy setting*, supplied complete with flexible hose, clamp bracket assembly,

slide bar, supports, soap dish, two parking sockets and hose retaining ring. Suitable

for connection to surface mounted shower controls. Available in chrome finish.

The adjustable spray handset is supplied with a low capacity spray plate fitted, a

high capacity plate is also supplied.

Rada Autotherm-3 EV CAT 5 Shower Fitting

Designed to comply with the requirements of a Fluid Category 5 risk installation (as

detailed in Water Regulations). As above but with special patented Security Hose

Retaining Ring** which replaces the standard hose retaining ring and no parking

sockets.

Rada BSM Shower Fitting

An adjustable spray handset,with three different spray actions. Supplied complete

with flexible hose, clamp bracket assembly, slide bar, hose retainer and supports.