6

INSTALLATION

General

The installation and maintenance of this unit must be carried out in

accordance with the instructions and information given in this Manual, and

must be conducted by designated, qualified and competent personnel.

1. Before commencing, ensure that the installation conditions comply with the

information given in the SPECIFICATION section.

2. Care must be taken during installation to prevent any risk of injury or damage.

3. All electrical connections should be in accordance with BS7671 and undertaken

by a competent person.

4. Isolate mains voltage supply before removing cover.

5. Installations must comply with all current Building and Electrical Regulations in

force, and relevant Guidelines.

6. The installation and usage environment of this product must not be subject to

extremes of moisture or temperature, unauthorised tampering or wilful abuse.

7. All solenoids must be approved to EN 60730-2-8.

Installation

The Rada Pulse Control Box is designed to interface with Rada Pulse sensors and

Rada Pulse solenoid valves (refer to individual Product Manuals for information)

which control the system functions.

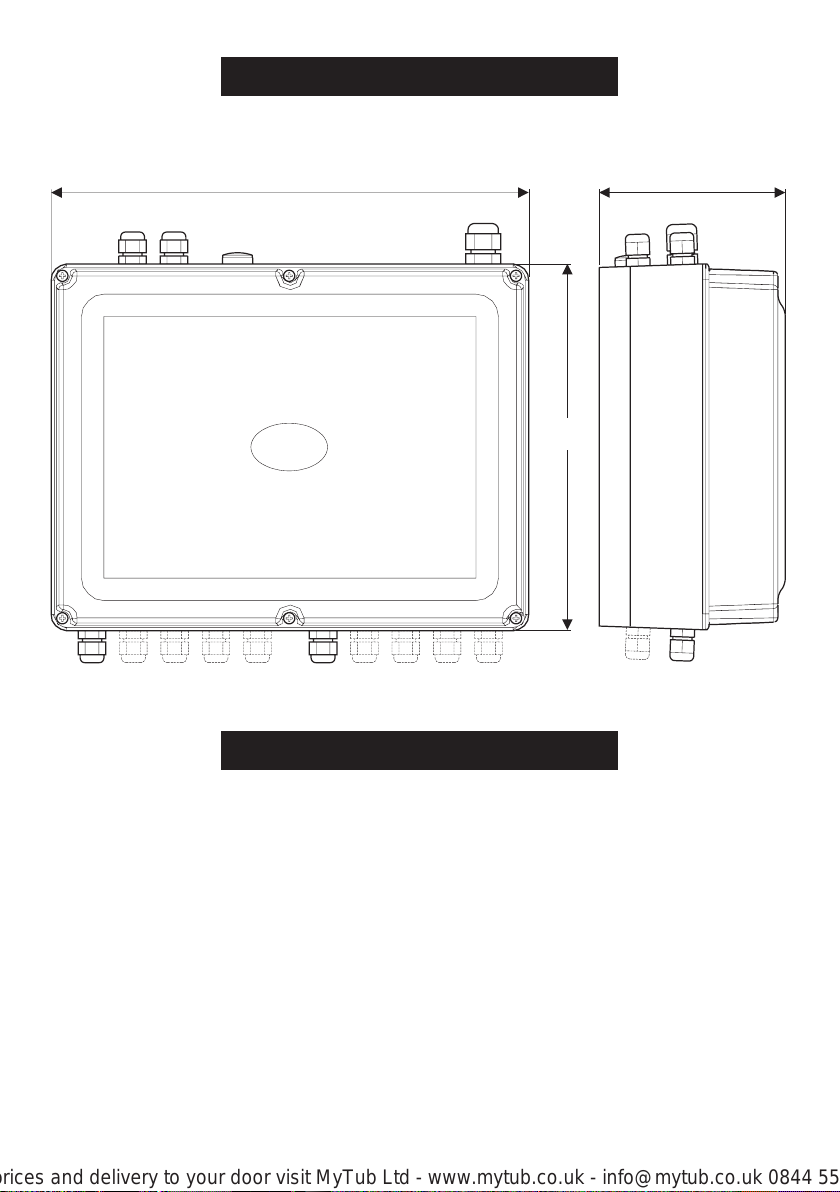

The enclosure is intended for wall-mounting to a suitable flat dry surface (fixing screws

are supplied), accessible for maintenance. Make sure that you fit the sealing washers

to the fixing screws before installation.

Note! An installation template is supplied so that the fixing positions can be marked

and drilled without putting the control box on the wall (If the wall is uneven it is

advisable to fit a board to ensure surface is flat and the control box does not become

distorted).

This appliance is intended for permanent connection to the fixed electrical wiring of

the mains electric system via a double pole switched connection unit fused at 3

amps, which has at least 3 mm contact separation.

A mains 230 V supply cable of 2 metre length is pre-connected, this must not be

removed; do not renew the cable inside the box if damaged.

For latest prices and delivery to your door visit MyTub Ltd - www.mytub.co.uk - [email protected] 0844 556 1818