Contents

Description........................................................................1

Autoclaving ......................................................................2

Operating Ranges ..............................................................2

Switching On ....................................................................2

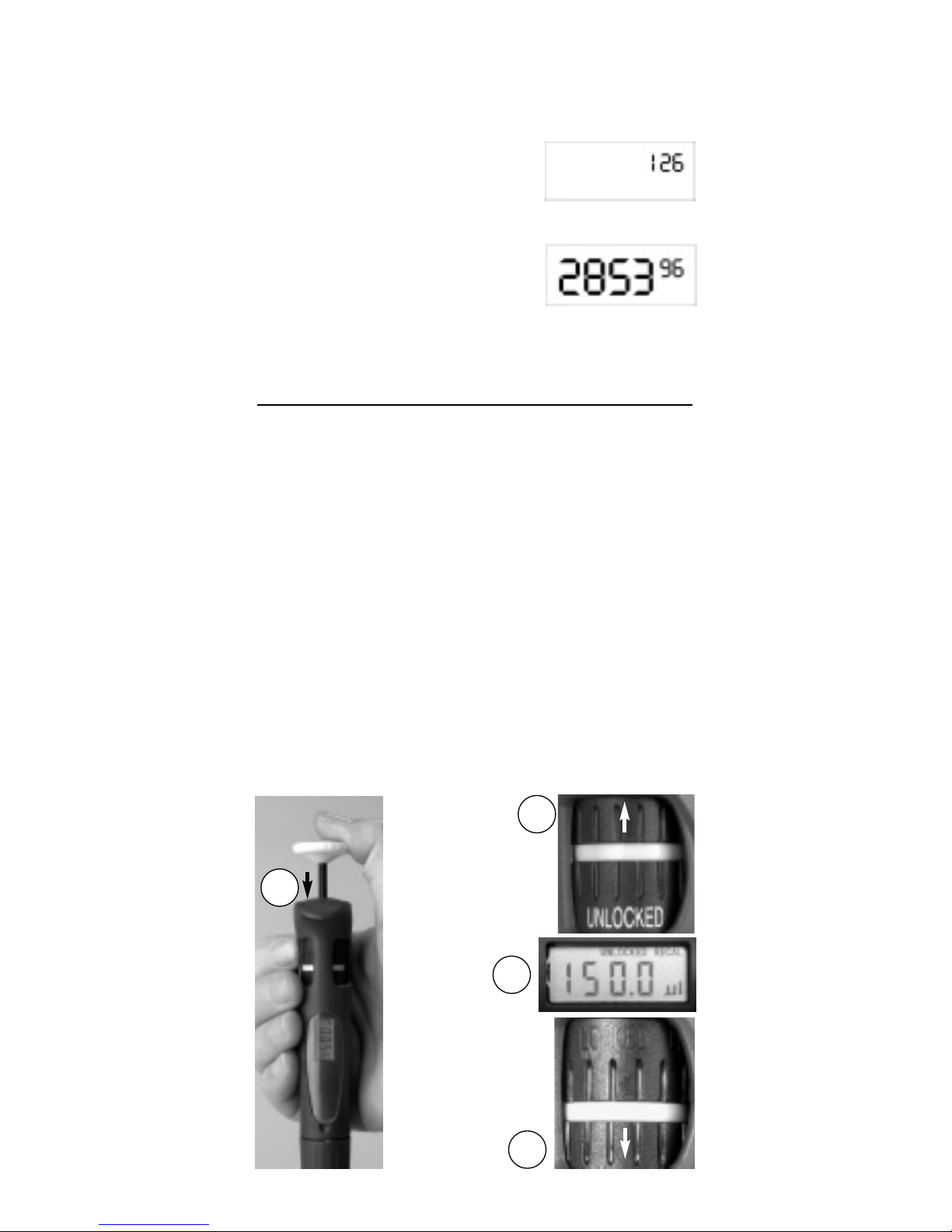

Volume indicator - LCD window ..........................................2

Setting the Volume ............................................................3

Tip Selection......................................................................4

Pipetting ..........................................................................4

Tip Immersion Depth ..........................................................5

Pipetting Guidelines & Precautions ......................................6

Reverse Mode Pipetting ......................................................6

Pipetting Liquids of Varying Density......................................7

Temperature Considerations ................................................7

Acids and Corrosives..........................................................7

Personalizing your Pipette ..................................................8

Name Tag Label ................................................................8

TIp-Ejector Extension ..........................................................9

Troubleshooting ..............................................................10

Error Messages................................................................11

Maintenance ..................................................................11

Cleaning and Decontamination..........................................16

Leak Test ........................................................................18

Recalibration ..................................................................18

Service, Calibration and Repair..........................................20

GLP Features ..................................................................20

Specifications ..................................................................21

Replacement Parts ..........................................................22

Pipetman Ultra Features

Parallax-free electronic display for easy volume setting

Flashing indicators if volume set is out of range

Ergonomic design, maximum comfort for left or right-handed use

Light, balanced, low ejection force

Simple to maintain and calibrate

GLP cycle counters

Parts Check List

The following items should be included.

Pipetman Ultra User's Guide

Calibration Tool Tube of lubricant (except U-2 & U-10)

Name-tags (5 different colors)

Certificate of conformity (including bar-code sticker).

If any item is missing, call 800-543-4030

Technical Assistance: 800-543-4030

Call this toll free number for technical consultation and product

information for Pipetman, RAININ pipettes, and disposable tips.

Pipetman and Microman are trademarks of Gilson Inc. U.S. and national patents pending.

Rainin is the U.S. distributor of Pipetman products.

Copyright 2003, Rainin Instrument, LLC.

Prices and specifications are subject to change without notice.