1About this Document 1

1.1 Objective and Target Group of this User Manual ...................................................... 1

1.2 Symbols and Typographic Conventions...................................................................... 1

1.3 Figures ........................................................................................................................ 2

1.4 Other Applicable Documents ..................................................................................... 2

1.5 Downloading Manuals................................................................................................ 3

2Safety 5

2.1 Intended Use .............................................................................................................. 5

2.2 General Safety Instructions ........................................................................................ 5

2.3 Organizational Measures............................................................................................ 5

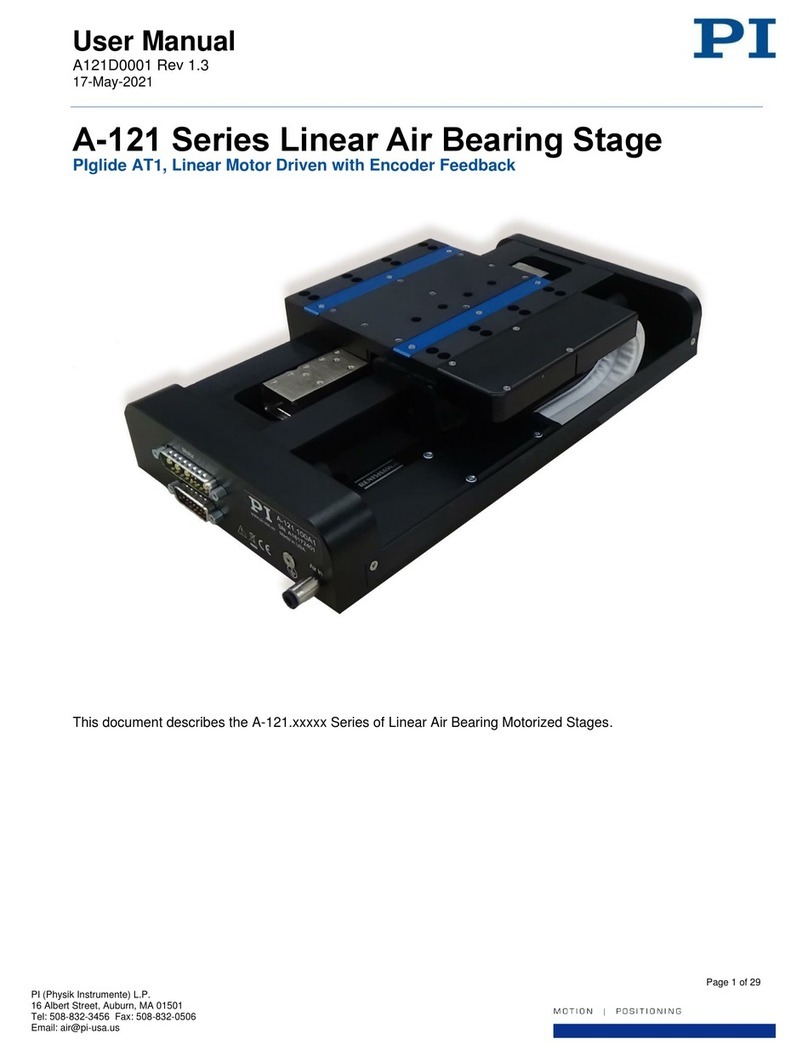

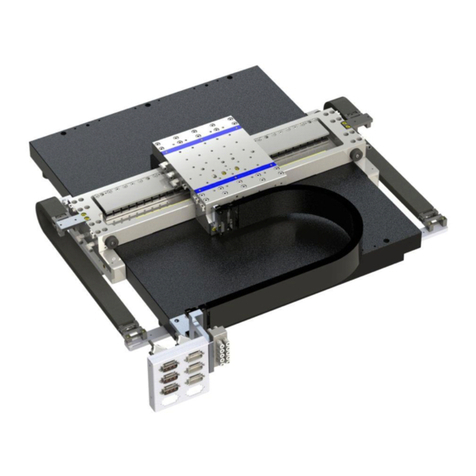

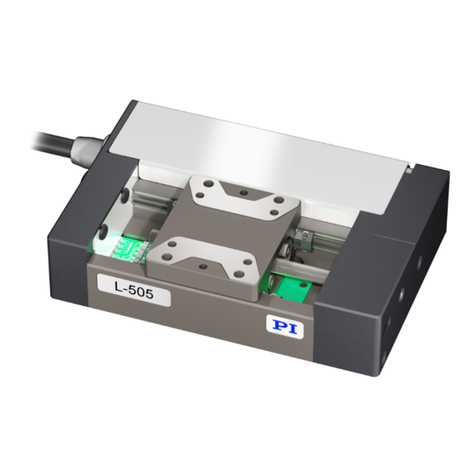

3Product Description 7

3.1 Features and Applications .......................................................................................... 7

3.2 Product View .............................................................................................................. 8

3.3 Technical Features...................................................................................................... 8

3.3.1 Struts.............................................................................................................. 8

3.3.2 Reference Switch and Limit Switches............................................................ 9

3.3.3 Control........................................................................................................... 9

3.3.4 Motion ........................................................................................................... 9

3.3.5 ID Chip.......................................................................................................... 13

3.4 Scope of Delivery...................................................................................................... 14

3.5 Optional Accessories ................................................................................................ 14

3.6 Suitable Controllers .................................................................................................. 15

4Unpacking 17

5Installing 19

5.1 General Notes on Installation................................................................................... 19

5.2 Determining the Permissible Load and Workspace ................................................. 20

5.3 Grounding the Hexapod ........................................................................................... 20

5.4 Mounting the Hexapod on a Surface ....................................................................... 21

5.5 Fixing the Load to the Hexapod................................................................................ 22

5.6 Optional: Removing the Coordinate Cube ............................................................... 24

5.7 Connecting the Hexapod to the Controller .............................................................. 24

Contents