2.0 Specications Rain Master Eagle User Manual

- 4 -

2.1.1 Water Conservation Features

• Flow sensing and control.

• Evapotranspiration (ET) based scheduling.

• Percentage adjustment on a per program basis to allow an increase or decrease of all station

runtimes within that program. e percentage will allow adjustment from 0 to 300% in 1%

increments.

Programmable rain shut o in order to delay the start of irrigation after a rain storm. e

controller will not water during the programmed shut o period (from one to seven days). After

the shut o period has expired the controller will return to the Automatic Mode of operation.

• Manual Rain Switch (Automatic Watering – No Watering) provides a means of quickly turning

o all irrigation programs without disturbing the stored program(s). When the switch is placed

in the No Watering position the display will show “RAIN OFF”.

• Connectivity for any one of the following: rain, moisture, or freeze sensor device. e

enabling of these devices can be performed on a per program basis. When the sensor is “active”

irrigation will stop and the display will indicate that the sensor is active. is feature allows

non-irrigation programs to execute independent of these devices.

• e ability to select either ODD or EVEN day watering on a per program basis. (When either

of these features is selected, the controller will not water on the 31st day of the month.)

• Selectable Cycle and Soak irrigation programming or conventional programming on a

preprogram basis.

• Programmable cycle runtime, Max Cycle Time, and Soak time on a per station basis.

• Automatic minimization of the water window by intelligently scheduling station starts when

other stations are satisfying their SOAK TIMES.

• Controller supports Quick Station programming in the Cycle and Soak programming mode.

• e controller provides a display of the total runtime of the program using the REVIEW

feature of the controller. e Cycle and Soak feature intelligently displays the total runtime of

the program, the controller considers all soak delays, optimized program features, water budget

percentage and inter-station delays.

• Optimized water savings, all station run times are calculated and executed to the nearest

second.

2.1.2 Convenience Features

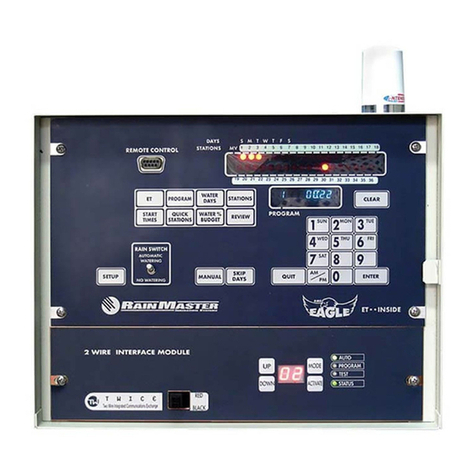

• Easy to understand and use keyboard layout, provides ease of use during programming and

review.

• Multiple displays provide a simple way of programming and information review.

• During program execution, the controller will display the executing program number, the ow

in GPM, and the station runtime countdown in hours, minutes and seconds.

• Programmable Controller Security Access code to prevent unauthorized use or modications to

be made of the controller’s programs. is feature is enabled by entering a security access code

from 1 to 4 digits in length.

• Review key to display all program parameters on a per program basis. Successive invocation of

the key will display program parameters one by one. Depression and subsequent hold of this

key will allow rapid review of program parameters.