1-800-563-4382 RAM Elevators + Lifts

Contents

Lift Diagrams ...............................................................................................................................................................2

Section 1: Introduction ................................................................................................................................................4

1.1: Online Resources ............................................................................................................................................................4

1.2: Installer Contact Information......................................................................................................................................4

Section 2: Safety Information....................................................................................................................................5

2.1: Safety Symbols and Definitions .................................................................................................................................5

2.2: Additional Symbols........................................................................................................................................................5

2.3: Safety Notes ....................................................................................................................................................................6

Section 3: Pre-Installation.........................................................................................................................................7

3.1: Tools....................................................................................................................................................................................7

3.2: Table of Provided Fasteners ......................................................................................................................................8

3.3: Site Preparation .............................................................................................................................................................9

3.4: Unpacking....................................................................................................................................................................... 10

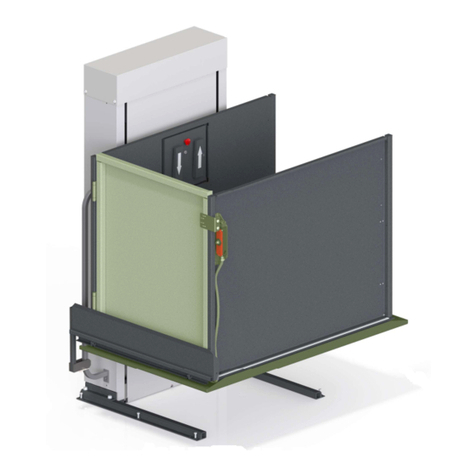

Section 4: Installation...............................................................................................................................................12

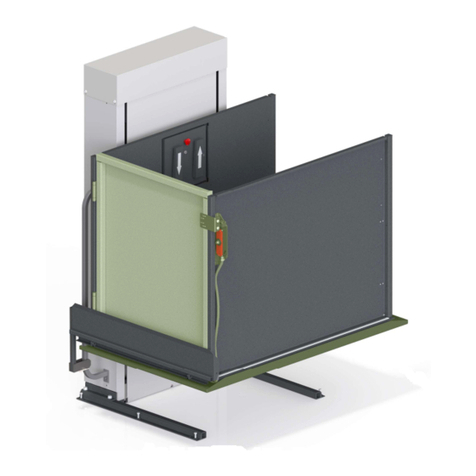

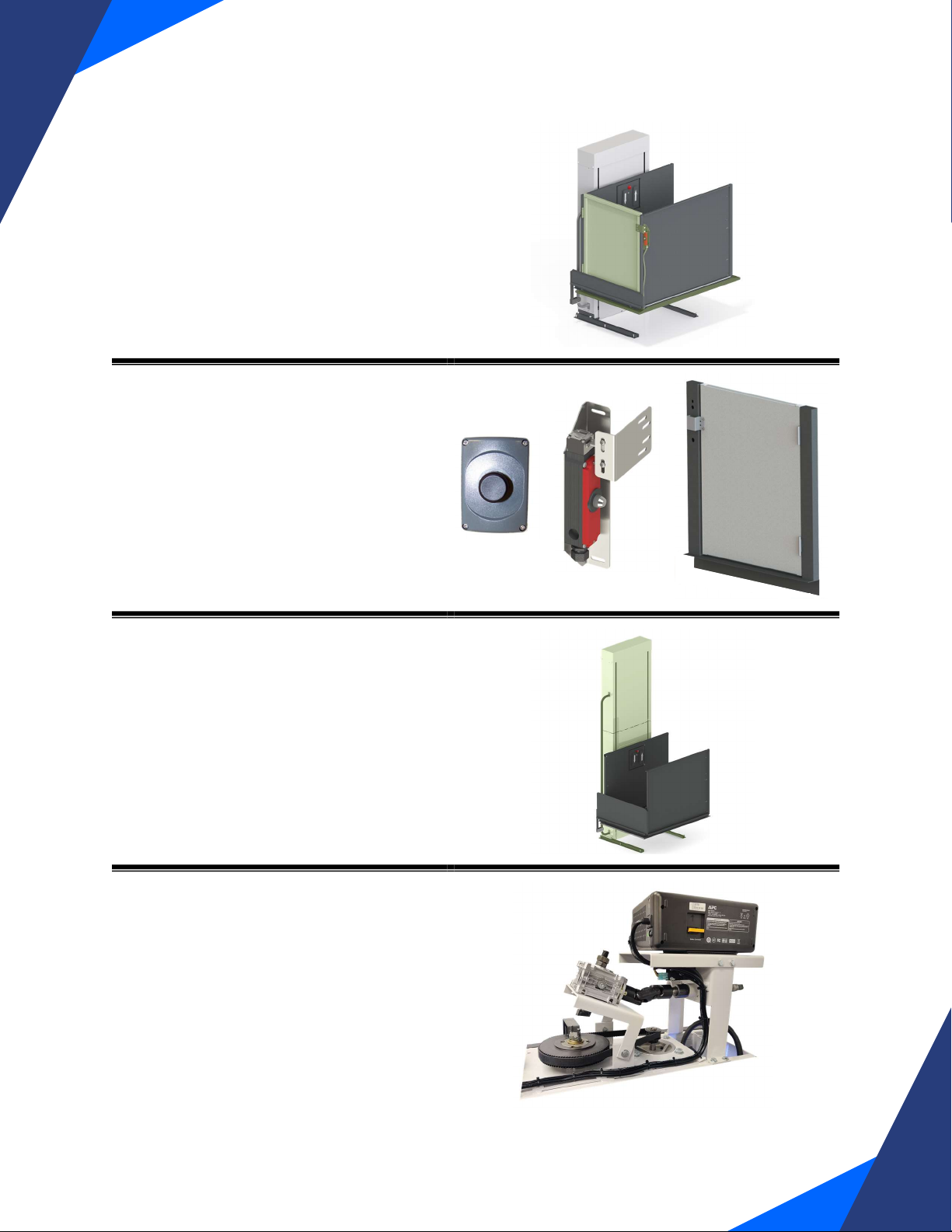

4.1: Base Frame .................................................................................................................................................................... 12

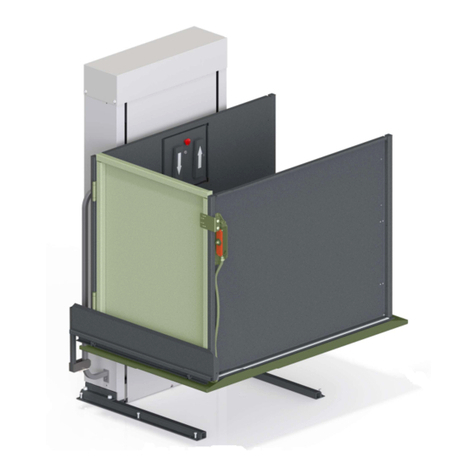

4.2: Locating Lift Keys ........................................................................................................................................................ 13

4.3: Platform.......................................................................................................................................................................... 14

4.4: Plug in and Test Operation ....................................................................................................................................... 16

4.5: Toe Plate......................................................................................................................................................................... 17

4.6: Platform Walls ............................................................................................................................................................. 20

4.7: Final Positioning & Leveling..................................................................................................................................... 21

4.8: Platform Tilt...................................................................................................................................................................22

4.9: Setting the Upper Limit Bracket .............................................................................................................................23

4.10: Anchoring .....................................................................................................................................................................25

4.11: Installing Additional Components..........................................................................................................................25

Section 5: Testing......................................................................................................................................................26

5.1: Full Load Testing...........................................................................................................................................................26

5.2: Upper Limit and Upper Final Limit Switch...........................................................................................................26

5.4: Lower Limit Switch .....................................................................................................................................................27

5.5: Additional Testing Notes............................................................................................................................................27

5.6: Reinstalling the Front Cover ................................................................................................................................... 28

Section 6: Troubleshooting ......................................................................................................................................29