RANCO INSTALLATION INSTRU CTIONS

HC ~INGlE HAGE ElECTRONIC TEMPERATURE CONTROL

PRODUCT DESCRIPTION

The Ranco ETC is a microprocessor-based

family of electronic temperature controls, de-

signed to provide on/off control for commercial

heating, cooling, air conditioning and refrigera-

tion. The ETC is equipped with a liquid crystal

display (LCD) that provides a constant readout

ofthe sensed temperature, and a touch keypad

that allows the user to easily and accurately

select the set point temperature, differential and

heating/cooling mode of the operation. Models

are available that operate on either line voltage

(120/208/240 VAG) or low voltage (24VAC).

With its wide temperature

setpoint range and selectable

heating or cooling modes, the

ETC can be used for a wide variety of

applications including refrigerated display

cases, walk-.inand reach-inr~frigerators,mHk coolers, refrigerated

warehouses, chillers, beefan1f-rreverage coolers, tank heating, space

and retum air temperature control and condenser fan cycling.

'Wide setpoint temperature range (-30°F to 220°F) and

differential adjustment (1°F to 30°F).

'Simple keypad programming of setpoint temperature,

differential and coolinglheating modes.

.LCD readout of sensor temperature, control settings,

relay status and onboard diagnostics.

•Remote temperature sensing up to 400 feet.

.SPDT output relay.

'User-selectable Fahrenheit/Celsius scales.

.Lockout switch to prevent tampering by unauthorized

personnel.

'Choice of line voltage and low voltage models available.

'Optional 0 to 10 volt analog outputavaHabla for remote

temperature indication.

InputVoltage

Temperature Range

DifferentialRange

SwitchAction

Sensor

120or 208/240 VAC (24 VAC optional),

50160

Hz

-30~t0220~

1°Fto 30°F

SPOT

Thermistor, 1.94 in. long x 0.25 in. diameterwith

8

ft.

cable

120/208/240VAC: 100 Milliamps

24 VAC: 2 - 6 VA

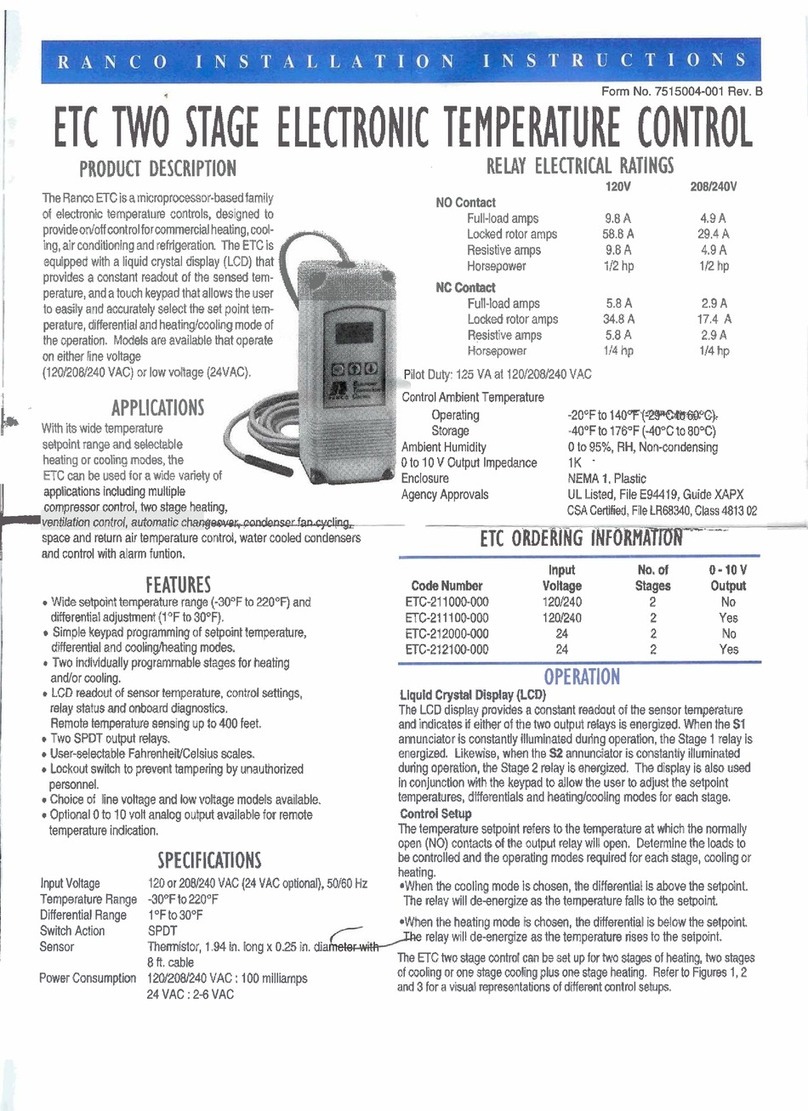

Relay Electrical Ratings 120V 20S/240V

NO Contact

Full-load amps 16A 8A

Locked rotor amps 96A 48A

Resistive amps 15A 8A

Horsepower 1 hp 1 hp

NC Contact

Full-load amps 5.8A 2.9A

Locked rotor amps 34.8 A 17.4 A

Resistive amps 5.8A 2.9A

Horsepower 1/4 hp 1/4 hp

Pilot Duty: 125 VA at 120/208/240 VAC

Control Ambient Temperature

Operating

Storage

Ambient Humidity

o

to 10 V Output Impedance

Enclosure

Agency Approvals

-20~ to 140°F (-29°C to 6D°G)

-40~ to 176°F (-40ce to 80°G)

o

to 95%, RH, Non-condensing

1K

NEMA 1, Plastic

UL Listed, File E94419, Guide XAPX

CSACertified,FHeLR68340,Class481302

Input No. of 0·10 V

Code Number Voltage Stages Output

ETC-111000-000 120/240 1 No

ETC-111100-000 120/240 1 Yes

ETC-112000-000 24 1 No

ETC-112100-000 24

1

Yes

OPERATION

Liquid Crystal Display (LCD)

The LCD display provides a constant readout of the sensor temperature and

indicates if the output relay is energized. When the S1 annunciator is

constantly illuminated during operation, the relay is energized. The display is

alsoused inconjunction with the keypad toallow the usertoadjustthe setpoint

temperature, differential and heating/cooling modes.

Control Setup

The temperature setpoint refers tothe temperature atwhich the normally open

(NO) contacts of the output relay will open. Determine the load

(5)

to be

controlled and the operating mode required, cooling or heating. Refer to

Figure 1 for a visual representation.

'When the cooling mode is chosen, the differential is above the setpoint.

The relay will de-energize as the temperature falls to the setpoint.

'When the heating mode is chosen, the differential is below the setpoint.

The relay will de-energize as the temperature rises to the setpoint.