GB

DO NOT OVERLOOK!

Maintenance and cleaning should only be carried out on painted and glass parts with soft non-abrasive cloths and cleaning liquids. Do not use any abrasive

pastes, wire wool or chemical cleaners e.g., thinners, acetone etc. The manufacturer is not liable for damage caused by wrong or careless use of cleaning

materials.

The manufacturer recommends the use of the following Ravak products: RAVAK ANTICALC CONDITIONER - To be used for perfect maintenance of the

protective Anticalc glass layer. This layer is factory applied to all safety glass panels. Easy application-perfect results. RAVAK DISINFECTANT - A solution with

significant disinfecting effects-intended for versatile use in every household, also recommended for maintenance of bathtub hydromassage systems. RAVAK

CLEANER-This highefficiency detergenthasapleasant fragrance.Theproduct complementsthe seriesof specialized chemicals by RAVAK.

Provided that installation is carried out in a professional manner and in accordance with above schedule, the product is subject to 24 months warranty.In

alternativecases, localcountry orEU laws willprevail. The manufacturer is notliable fordamage causedby incorrect installation, use ormaintenance.

Forfurther information,contact yourlocal Ravak dealer.

Themanufacturer reservesthe rightto amend orimprove onexisting designsor features.

Please help preserve the environment by observing local country guidelines or laws regarding re-cycling. Materials which are not suitable for re-cycling must be

disposedof atan officialandsuitable wastecontrol centre.

ASSEMBLY INSTRUCTIONS

TWO-PART SHOWER DOOR GSD2

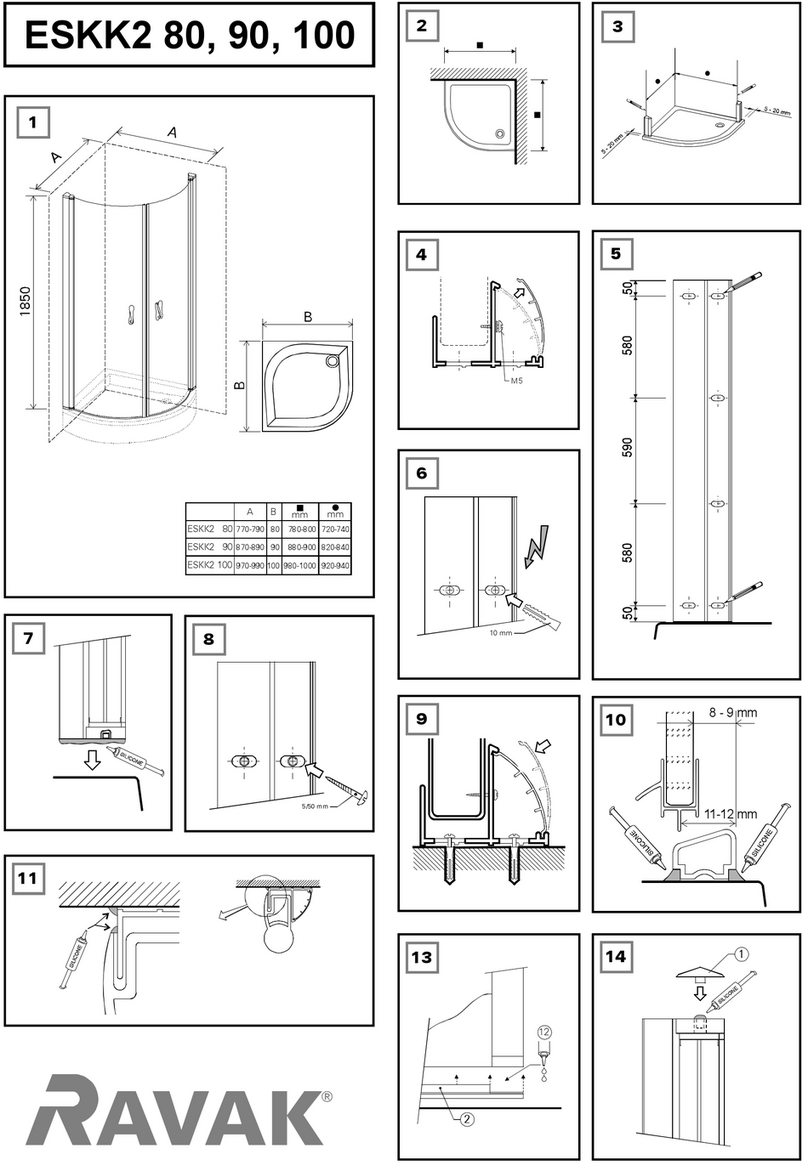

The product is for mounting in a totally finished (tiled, plumbed, etc.) bathroom and fitted shower tray (if used). The constructional dimensions and/or shower tray

dimensions must be in strict accordance with the dimensions of the selected shower door or enclosure i.e. nominal 80, 90, 100, 110, or 120 cm. according to type.

Forbest results,the productmust only befitted toa strongand rigid,solid bathroom wallthat isvertical andadjacent wallsshould be squareto eachother.

WARNING:whenmanipulating theglass panels, alwaysensure thatsome softmaterial isplaced under thebottom edge,for protection.

Un-pack and prepare individual glass components according to the scheme for left (and right) variants. The glass for the fixed wall with a thickness of 8mmat

the wall has two fixing holes and on the other side there are 4 holes for door hinges. The door glass has 2 holes for hinges and on the other side there is 1 hole for

thehandle halfwayup theheight of thedoor.Markson theglass mustbe readablewhen viewed fromthe outside.

Fit the long plastic sealing profile to the vertical edge of the fixed glass wall on the side where it will contact the wall. For easier manipulation, dampen the seal

witha littlesoapy water. (Item1)

Ontothe oppositeedge ofthe fixed glasswall, fitthe longsoft edgeddoor seal. (Item2)

Fit to the fixed glass wall, the dismantled halves of the hinges, the lower part of the hinges, with the side for the screw on the inner side of the glass. Repeat with

theupper hingeparts ontothe folding door.Ensure thatprotection piecesare in place.Never fithinges directlymetal toglass without theprotection pieces.

Onto thewall edgeof thefixed glass wall, mount the wall brackets, angled side on the inner side,flat sideon theouter sideand lightlytighten. The final tightening

forceafter alladjustments aremade should be4-5Nmtorque.

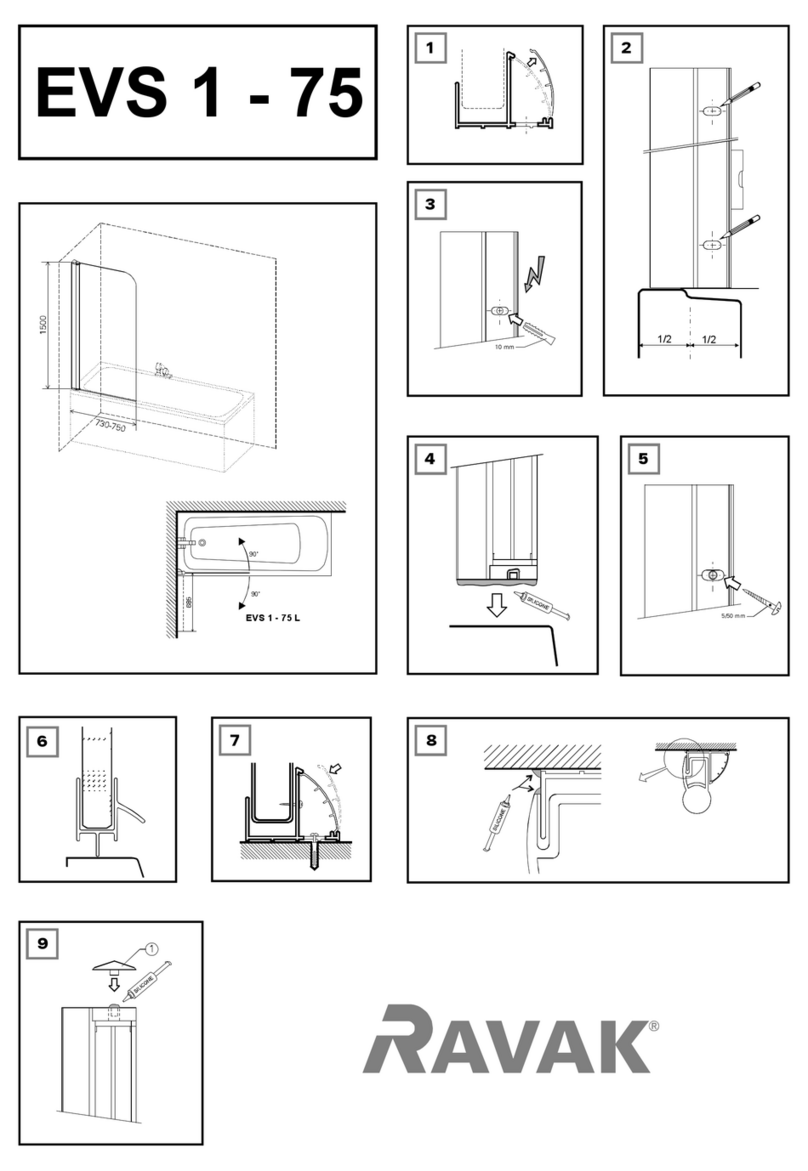

According to the diagram 6, measure and mark points for drilling from the top of the shower tray (or tiling) up for the centre of the bracket holes. The front face of

the fixed glass wall should sit 19 mm from the outer edge of the shower tray and the centres of the mounting brackets should be 55 mm from the outer edge of the

shower tray. Insert the temporary white moulded plastic parts under the glass wall so that it will have a 2 - 3mm space underneath for later filling. Ensure correct

measurementsare maintainedand thatmeasurement points arevertical bya spiritlevel.

Drill 2 holes 8 mm dia. to depth of 60 mm. Fit the special 'Mungo' plastic wall plugs. Onto the opposite side of the niche, again mark for four holes in accordance

with the diagram, 23 mm from the edge of the shower tray. Drill four holes 8 mm dia. and insert the four ordinary plastic wall plugs. Screw the aluminium profile to

the wall with four 3,5 x 50 mm screws and fit the magnetic strip/plastic profile onto the aluminium profile with the angle face pointing outwards. (Picture 2 - 3). For

easiermanipulation, dampenthe profilewith a littlesoapy water.

Washers and screws are included for fitting components to traditional walls of brick and plaster or cement. If other wall materials are used, other full strength

fitting components must be utilised in accordance with manufacturers advice. Safe working load of Mungo wall plugs is 4,5 kN. For fastening the profile, use four

wallplugs.

Setfixed glasswall vertical,fit and tightenthe two5 x60 mmscrews. For settinglevel tothe base,adjust thewhite moulded plasticparts, asnecessary.

Fit the magnetic seal profile to the door with the angle face pointing inward. (Picture 2 - 3). Fit the door onto the hinges. Fit the door handle with the correct

plasticsleeve inthe holeof the doorand plasticwashers betweenthe handlesand the glass.Never fitmetal directlyto glass.

Adjustthe doorso thatit is level.Check thecontact ofthe magnetseals against eachother ensuringthey meettogether correctlyfor the wholevertical length.

The gap between the door glass and the fixed glass wall must be even and approximately 4 mm when the door is in the closed position. The soft seal will fill this

space.

Ifnecessary,loosen thescrews inthe bracketsof thefixed glasswall.The doorcan then be moved by± 6mm. The plasticwith magneticstrip profilecan alsobe

partiallyadjusted byup to5 mm bymoving iton thealuminium profile.Never adjust theopposite plasticwith magneticstrip profile,which is attachedto thedoor.

When the product is correctly adjusted, it should have the top edges of the glass panels level with each other and horizontal. The edges of the door and fixed

wall panel must be level with the shower tray edge and the magnetic strips must make proper contact over the whole length of the strip. In the case of uneven walls

or tiling, it is possible to make compensation by using the flexible mounting washer part underneath the relevant wall bracket. (Diagram 14). The brackets must be

in one vertical line and the gap between the upper and lower part of the hinge must be the same for both hinges. The final gap under the fixed wall should still be 2 -

3mm andunder theglass door shouldbe 32- 33mm.

DOUBLECHECK tightnessof allconnections.Tighteningtorque ofglass againstbrackets or hingesshould be4-5Nm.

Ensurethe sealingprofile betweenthe fixed glasswall andtiled wallis pushedhard in.

Onto thelower edgeof the door,use siliconputty tofit the smalldraining seal.

Usesilicon puttyto fitthe threshold stripparallel withthe door. Thecorrect position is9 mmfrom theouter edgeof the glass.

Using the Ravak transparent silicon putty, fill all seals from the external side of the vertical connections between the fixed glass wall and the tiling and between

the opposite wall tiling and the aluminium profile. Discard the temporary plastic pieces and fill the horizontal gap underneath the fixed glass wall. Fill along the

edges of the threshold strip. Fill along the edges of the small draining seal. Place a knob of silicon on top of the bracket screws and press into place the stainless

steelbracket coverswith theflat face outermost.When set,remove theprotective foil.

Where this component is part of the product contents, attach the strut to the upper edge of the fixed glass wall(s). Find the position where the opposite end touches

the wall and make a mark for the centre of the wall bracket. Drill a hole 8 diameter x 60 deep. Fit a wall plug and screw bracket to wall witha5x60screw. Fasten the

oppositeend tothe glasswith bolt M8x 8mm

ASSEMBLYSEQUENCE:

1.

2.

3.

4.

5.

6.

7.

Warning:Becareful toavoidelectric, waterand gaspipes hiddenbeneath plasterwork ortiling.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.Alternativemounting strut: