1

11

1 General information

2 9936092x – V04 2012/02

Contents

1

11

1 General information

General informationGeneral information

General information

................................

................................................................

................................................................

................................................................

................................................................

................................................................

.........................................

..................

.........

3

33

3

1.1 Scope of these instructions .......................................................................................... 3

1.2 Designated use ............................................................................................................ 3

2

22

2 Safety instructions

Safety instructionsSafety instructions

Safety instructions

................................

................................................................

................................................................

................................................................

................................................................

................................................................

...........................................

......................

...........

4

44

4

3

33

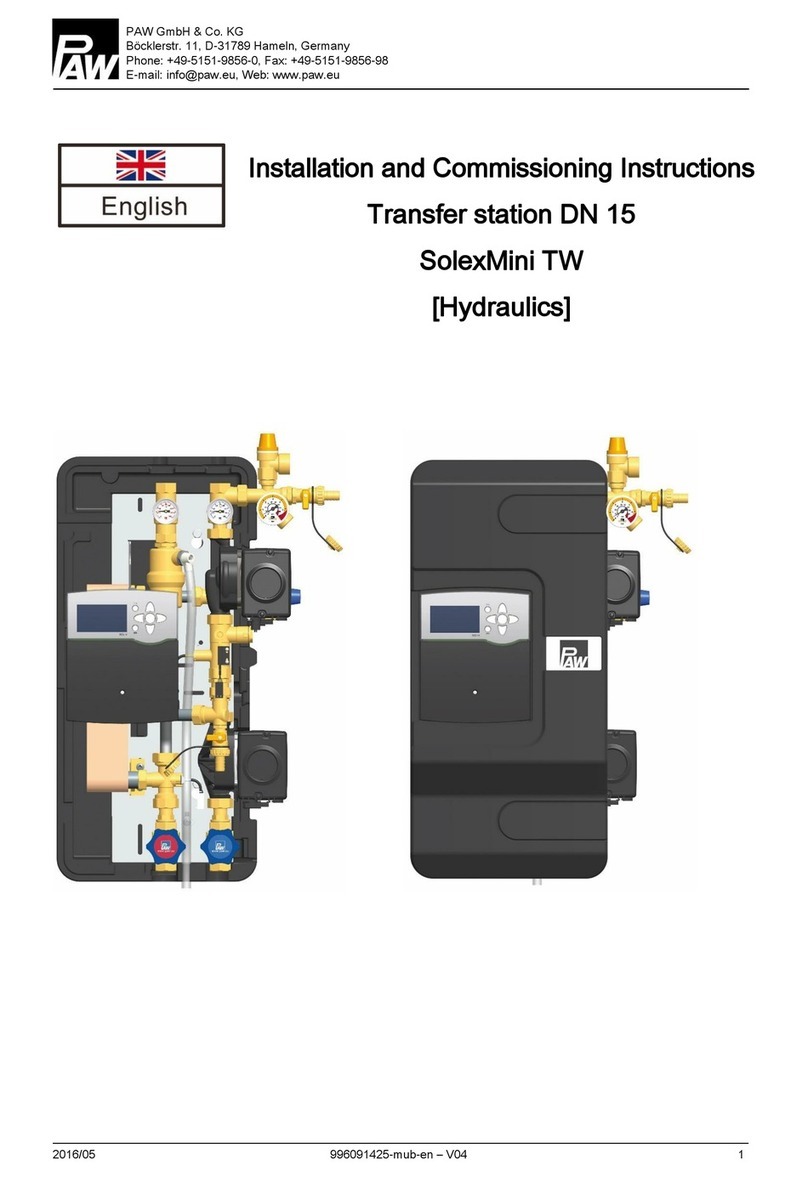

3 Product description

Product descriptionProduct description

Product description

................................

................................................................

................................................................

................................................................

................................................................

................................................................

..........................................

....................

..........

5

55

5

3.1 Equipment .................................................................................................................... 5

3.2 Function ....................................................................................................................... 6

3.2.1 3-temperature mixing valve [specialist] .................................................................. 7

3.2.2 Change of the flow line [specialist] ........................................................................ 8

3.2.3 Check valve and non return valve [specialist] ...................................................... 11

3.3 Optional equipment: actuator [specialist] .................................................................... 12

4

44

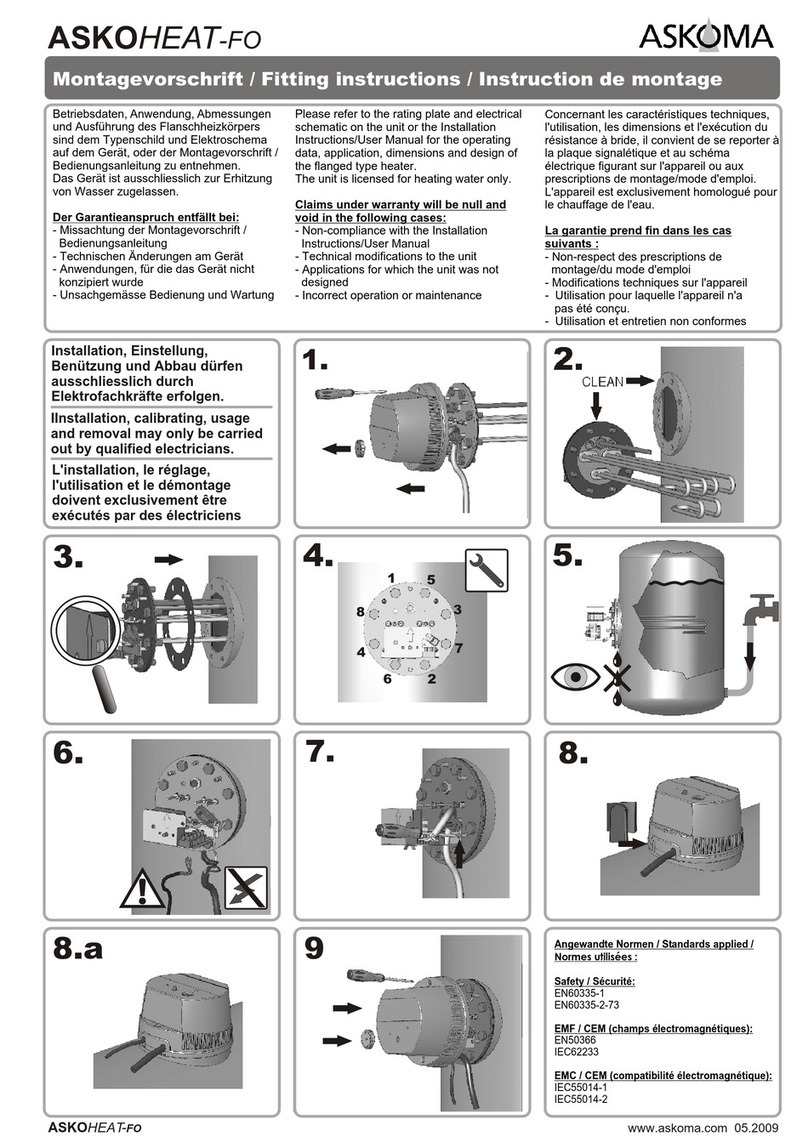

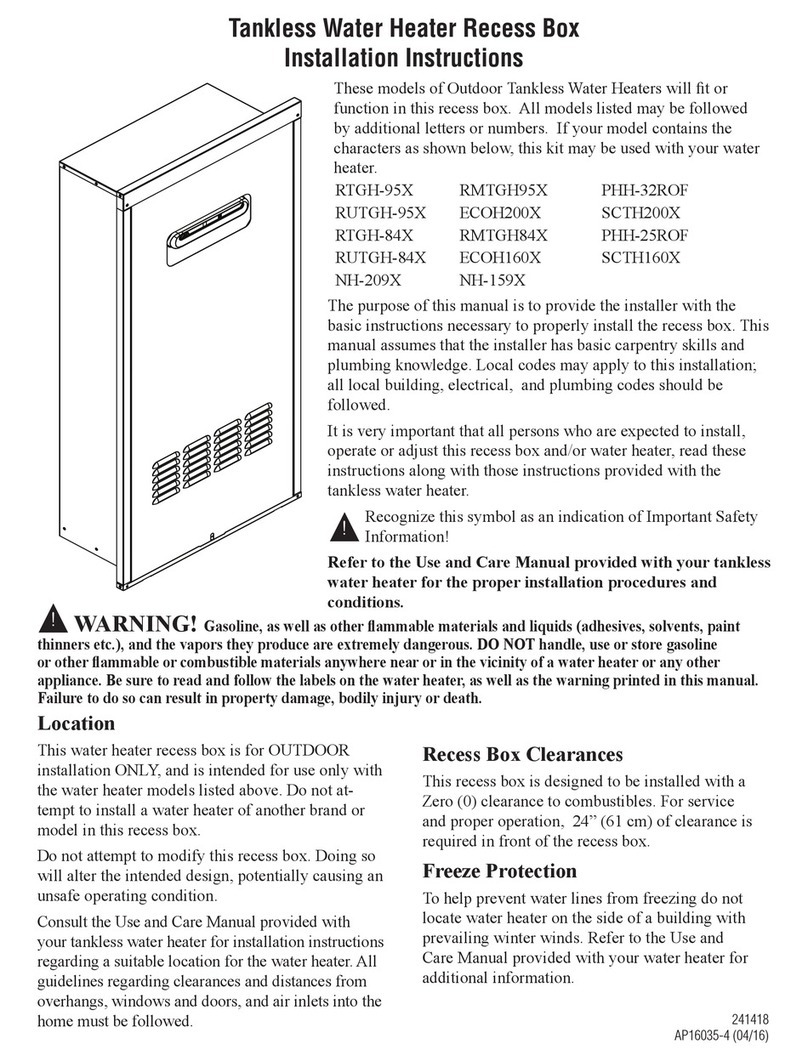

4 Assembly and installation [specia

Assembly and installation [speciaAssembly and installation [specia

Assembly and installation [specialist]

list]list]

list]

................................

................................................................

................................................................

................................................................

..............................................

............................

..............

13

1313

13

4.1 Accessories: compression fitting (not included in delivery) ......................................... 13

4.2 Assembly of the heating circuit ................................................................................... 14

5

55

5 Scope of delivery [specialist]

Scope of delivery [specialist]Scope of delivery [specialist]

Scope of delivery [specialist]

................................

................................................................

................................................................

................................................................

..........................................................

....................................................

..........................

16

1616

16

6

66

6 Technical data

Technical dataTechnical data

Technical data

................................

................................................................

................................................................

................................................................

................................................................

................................................................

...............................................

..............................

...............

17

1717

17

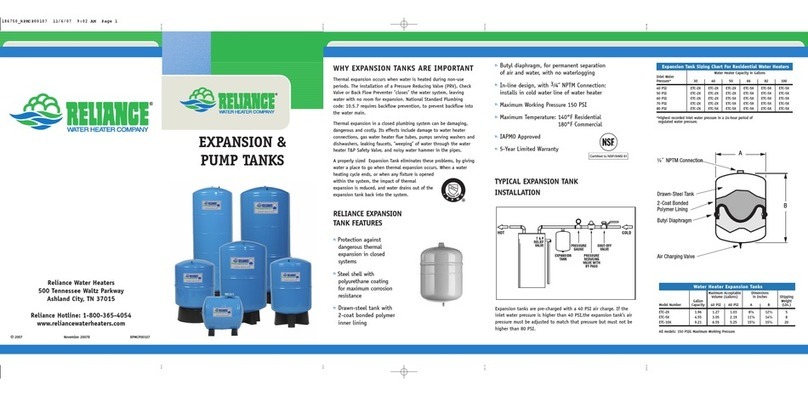

6.1 Pressure drop and pump characteristics .................................................................... 18

Item no. 9936092x – Version V04 – Issued 2012/02

Translation of the original instructions

We reserve the right to make technical changes without notice!

Printed in Germany – Copyright by PAW GmbH & Co. KG

PAW GmbH & Co. KG

Böcklerstr. 11

31789 Hameln, Germany