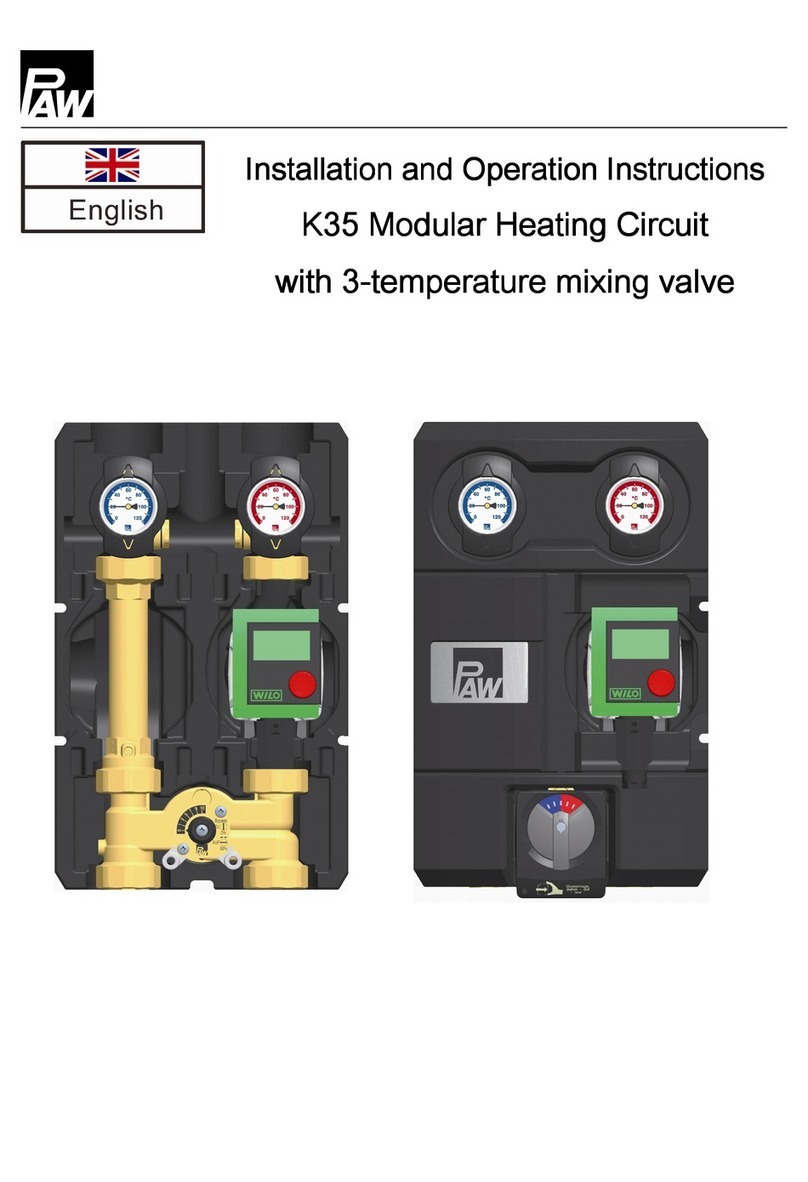

1 General information

2 996091425-mub-en –V04 2016/05

Contents

1General information .........................................................................................................3

1.1 About these instructions................................................................................................ 3

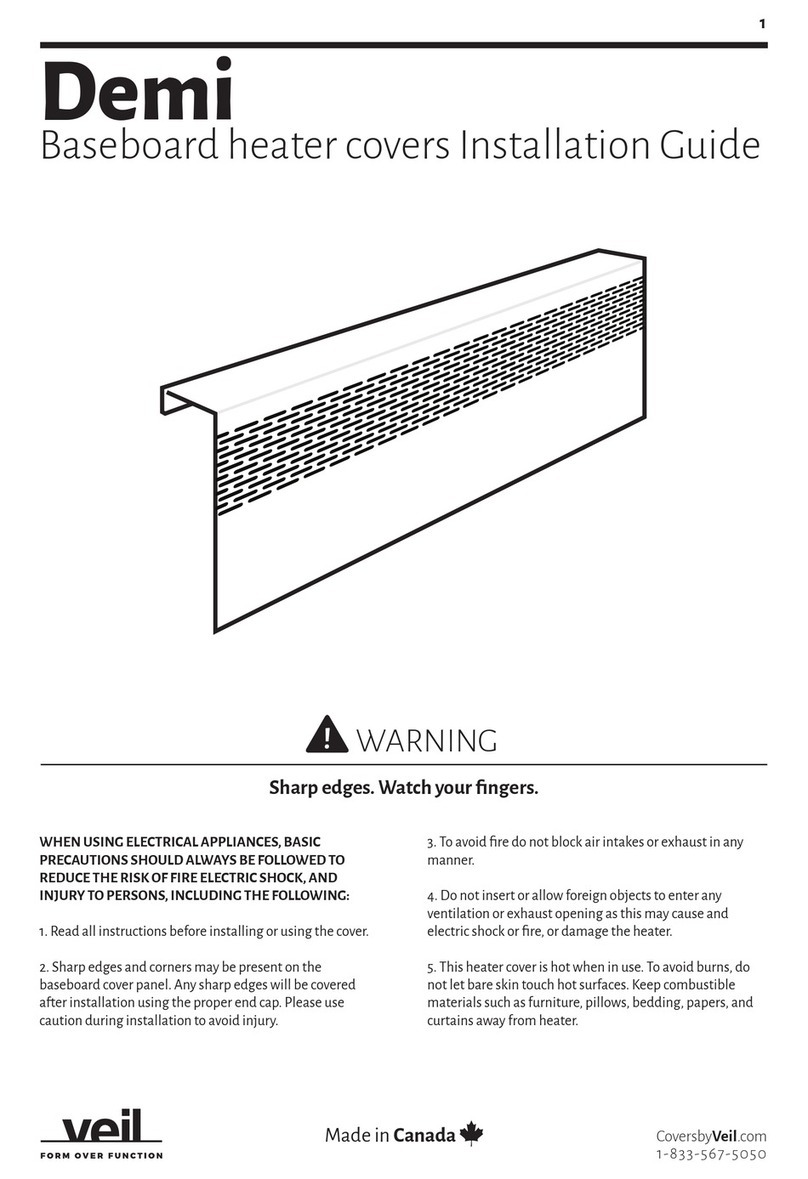

1.2 About this product......................................................................................................... 4

1.3 Designated use............................................................................................................. 5

2Safety instructions ...........................................................................................................6

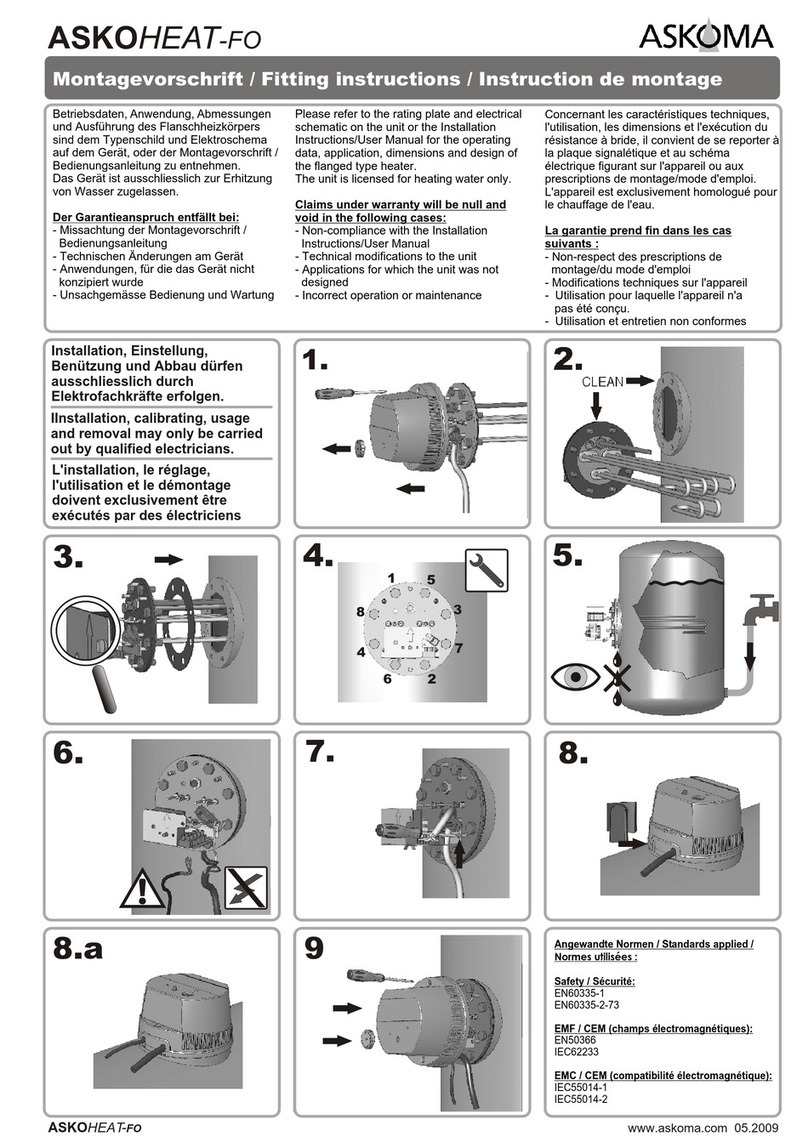

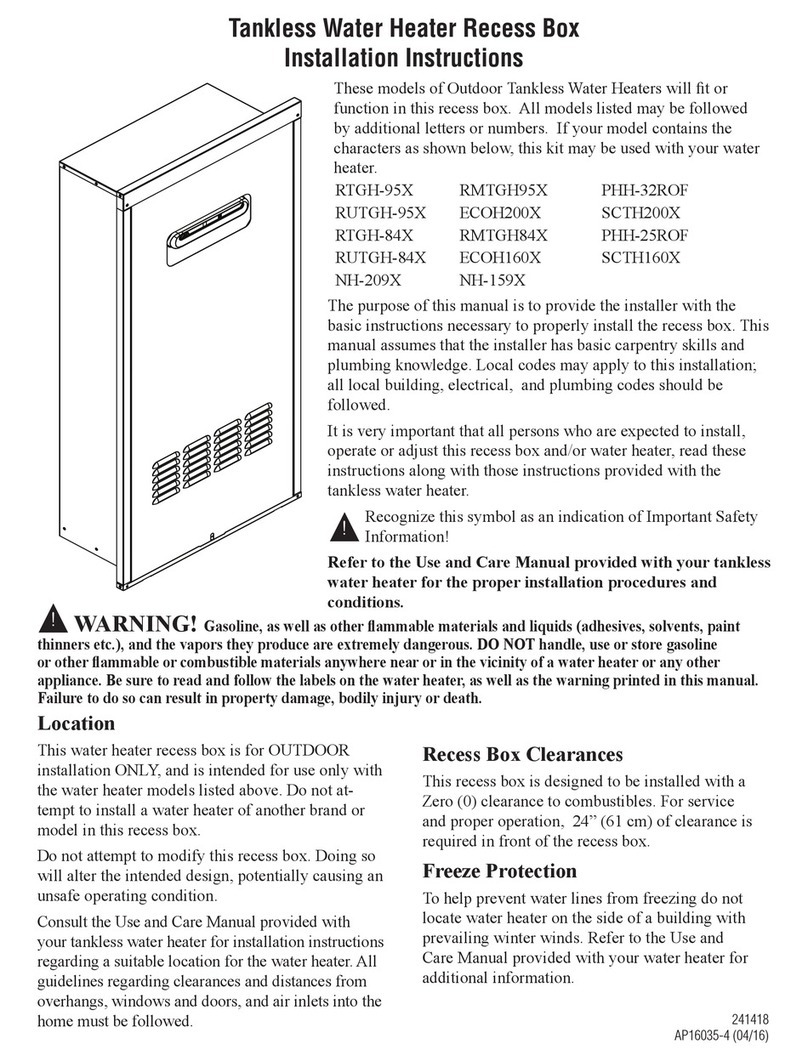

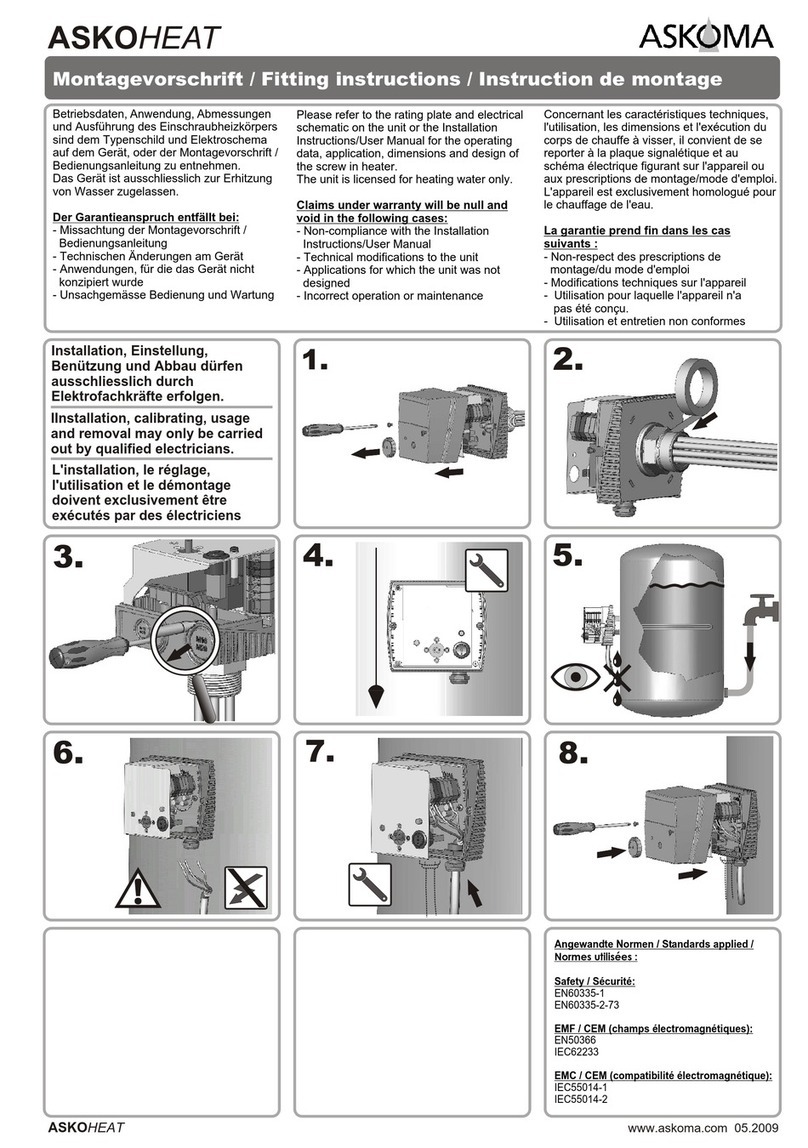

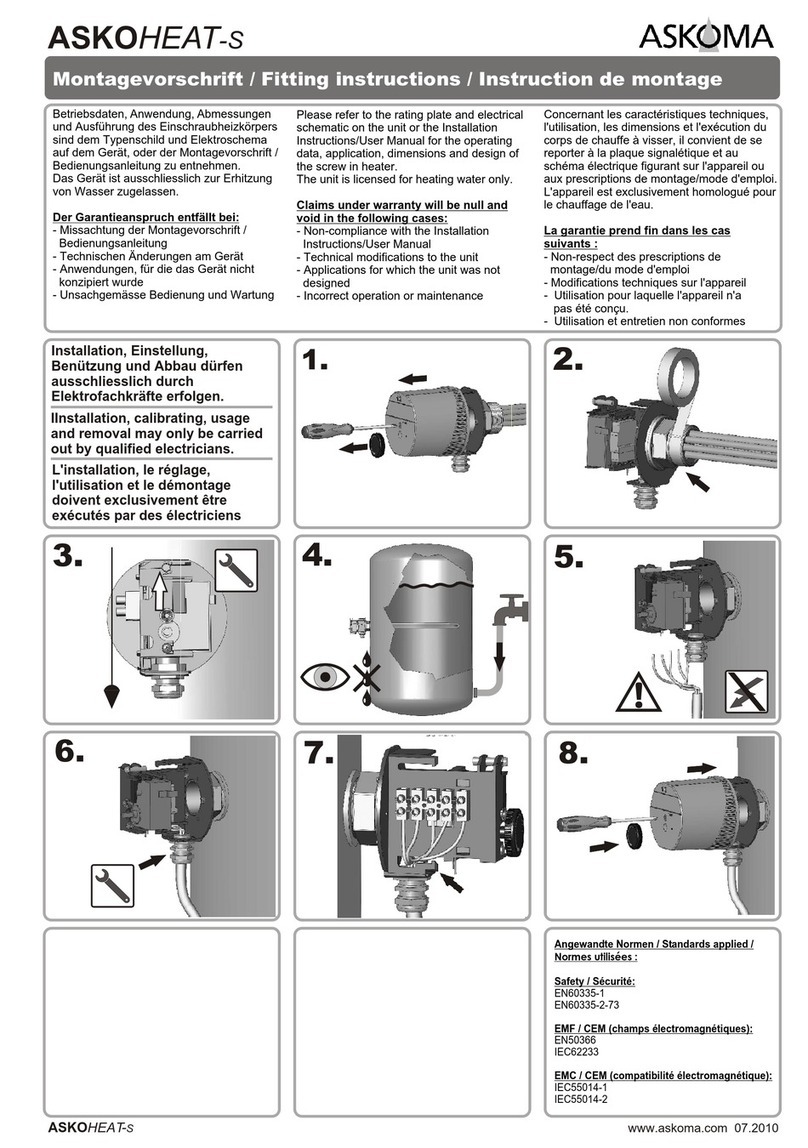

3Assembly and installation [specialist]................................................................................8

3.1 Controller connection.................................................................................................. 11

4Commissioning [specialist].............................................................................................12

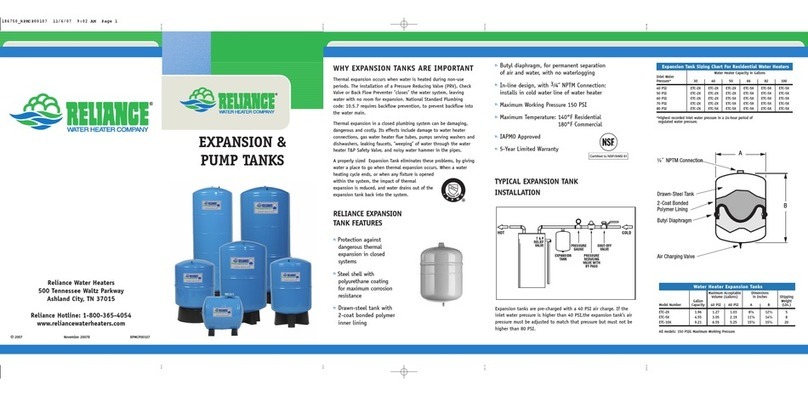

4.1 Flushing and filling the secondary circuit..................................................................... 13

4.2 Flushing and filling the solar circuit ............................................................................. 14

4.3 Parameters: SolexMini TW with controller SC5.14...................................................... 19

5Maintenance [specialist].................................................................................................20

5.1 Draining the solar circuit ............................................................................................. 21

5.2 Deinstallation.............................................................................................................. 21

6Spare parts [specialist] ..................................................................................................22

6.1 Primary circuit SolexMini TW (6091425) ..................................................................... 22

6.2 Secondary circuit SolexMini TW (6091425) ................................................................ 23

7Technical data...............................................................................................................24

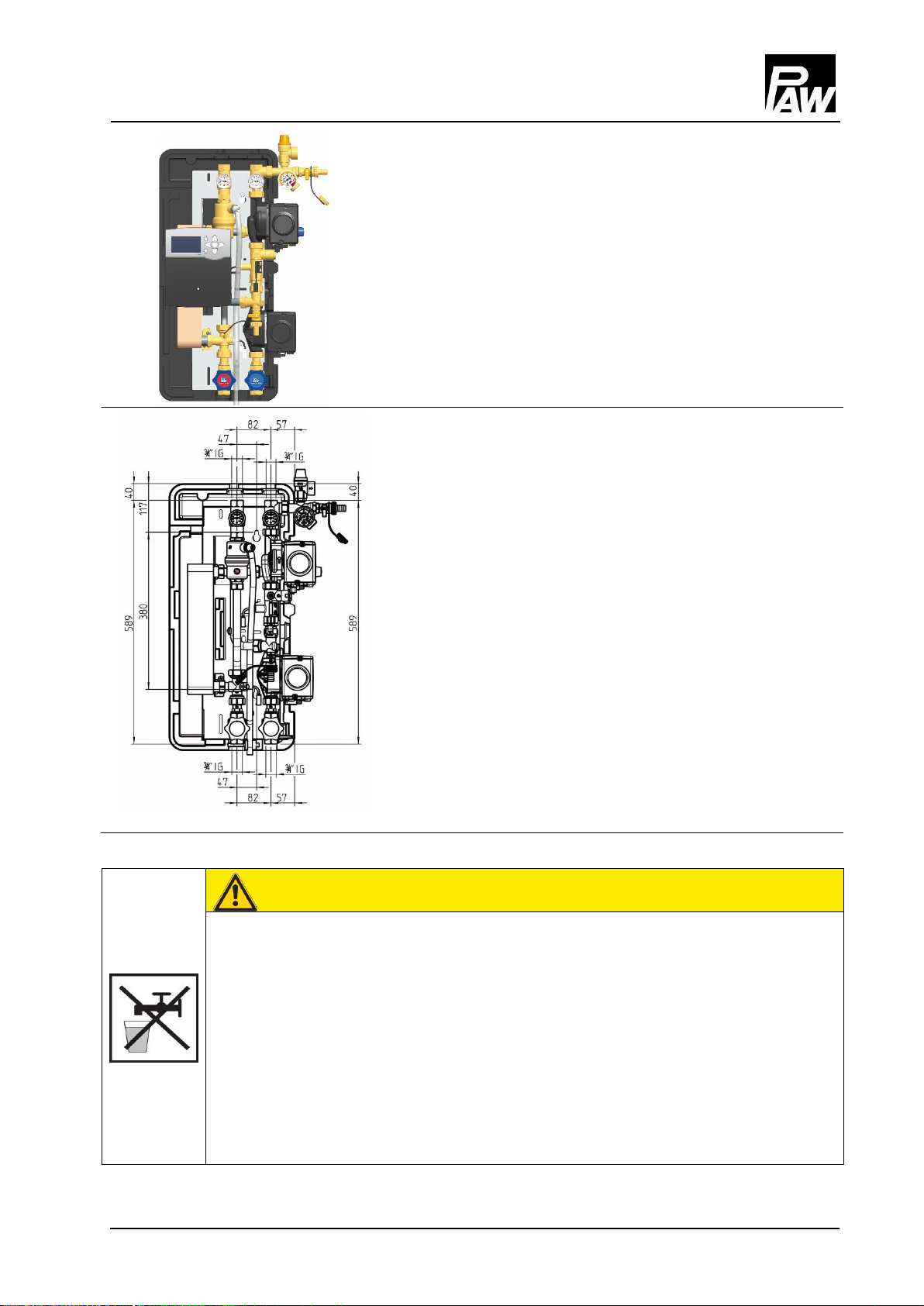

7.1 Dimensional drawing SolexMini TW............................................................................ 25

7.2 Pressure drop characteristic curve SolexMini TW....................................................... 25

8Function of the check valves [specialist] .........................................................................26

9Commissioning report....................................................................................................28

Item no. 996091425-mub-en - Version V04 –Issued 2016/05

Translation of the original instructions

We reserve the right to make technical changes without notice!

Printed in Germany –Copyright by PAW GmbH & Co. KG

Böcklerstraße 11

D-31789 Hameln, Germany