3

Revised 03/2023 Drawing No. LP0911

For hazardous location installation the following shall be taken

into consideration:

- When used in a Zone 22 environment, the device shall be

panel mounted in at least Zone 22 IECEx/ATEX-Certified

tool accessible enclosure with a minimum ingress protection

rating of at least IP64 as defined in IEC/EN 60529.

- When used in a Zone 2 environment, the device shall be

panel mounted in at least Zone 2 IECEx/ATEX-Certified tool

accessible enclosure with a minimum ingress protection

rating of at least IP54 as defined in IEC/EN 60529.

- This device is open-type and must be mounted in a suitable

dusttight end-enclosure in accordance with articles 500 and

502 of the NEC and positioned so only the face of the

display is exposed.

- Must be wired using Division 2 wiring methods as specified

in article 501-4(b), 502-4(b), and 503-3(b) of the National

Electric Code, NFPA 70 for installation within the United

States, or as specified in section 19-152 of Canadian

Electrical Code for installation in Canada.

CONNECTING TO EARTH GROUND

Each operator panel has a chassis ground terminal on the back

of the unit. Your unit should be connected to earth ground. Steps

should be taken beyond connecting to earth ground to eliminate

the buildup of electrostatic charges.

The chassis ground is not connected to signal common of the

unit. Maintaining isolation between earth ground and signal

common is not required to operate your unit. But, other equipment

connected to this unit may require isolation between signal

common and earth ground. To maintain isolation between signal

common and earth ground care must be taken when connections are

made to the unit. For example, a power supply with isolation

between its signal common and earth ground must be used. Also,

plugging in a USB cable may connect signal common and earth

ground.1

1USB’s shield may be connected to earth ground at the host.

USB’s shield in turn may also be connected to signal

common.

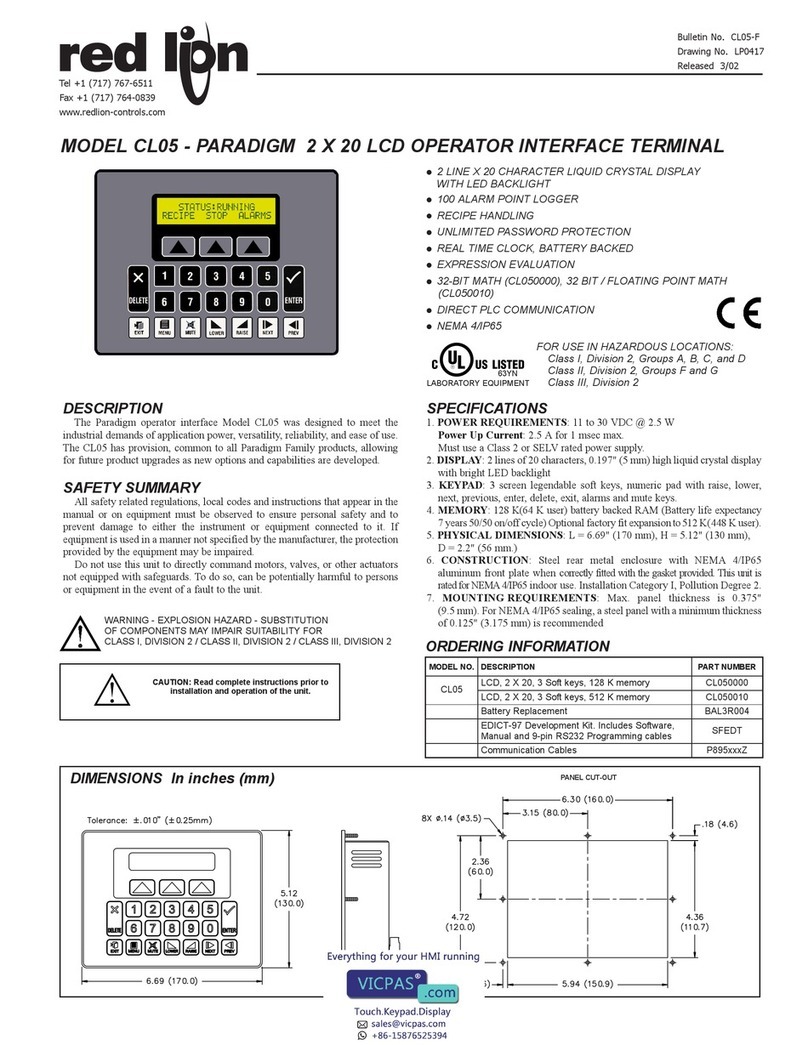

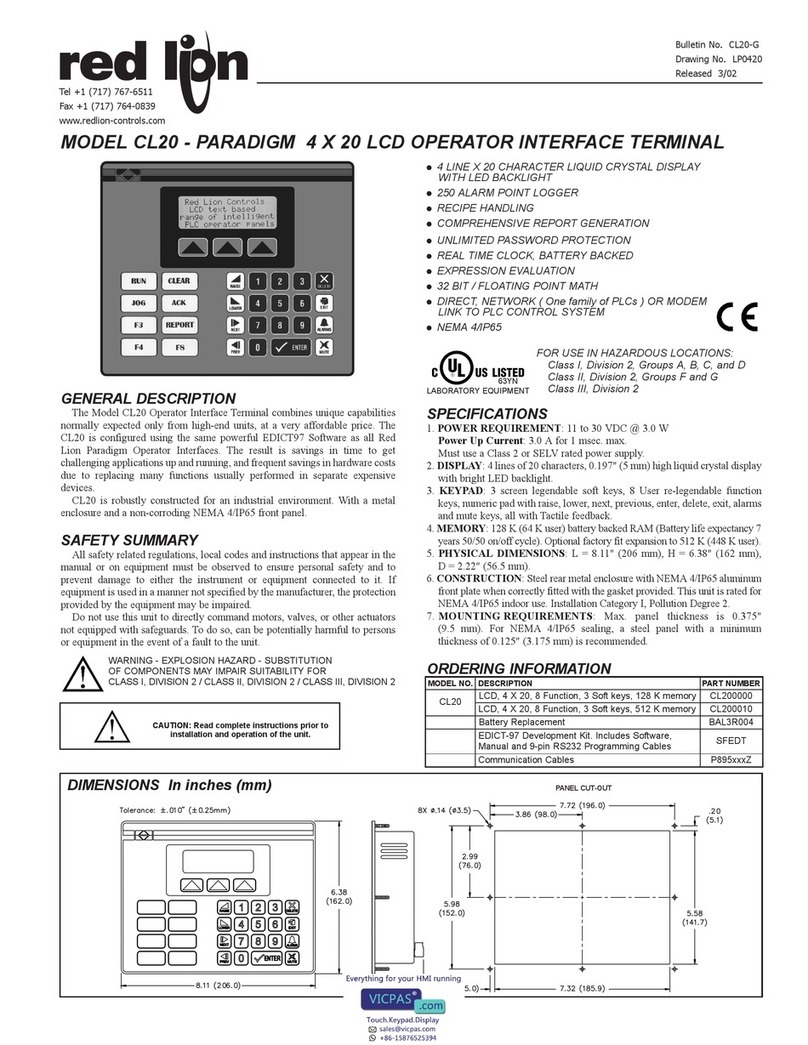

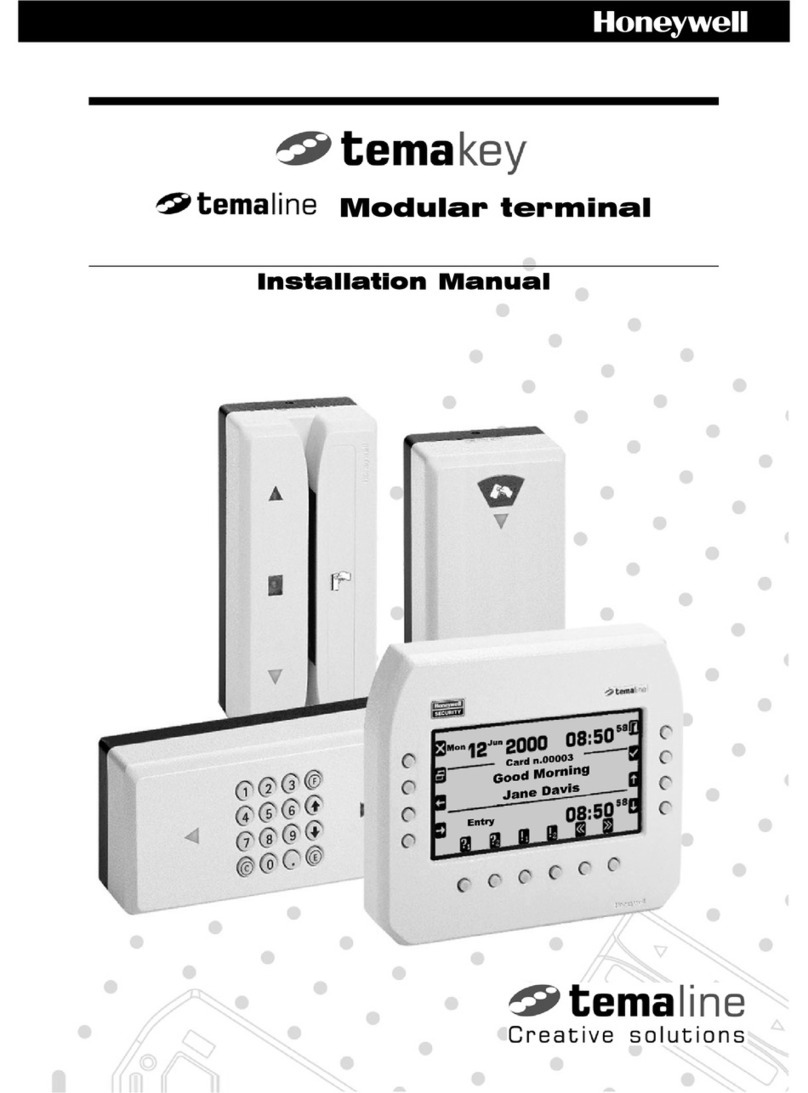

TYPE B

COMMS PORT

TxB

USB

TxA (PIN 8)

TxEN

COMM

RxB

TxB (PIN 1)

TxA

RxA

PORT B

PORT A

ETHERNET

STATUS

USB HOST

(NIC)

AUXILIARY

TxA

(NIC)

STATUS

ETHERNET

COMM

RTS (PIN 6)

Tx

CTS (PIN 1)

Rx

COMM

TxA (PIN 8)

TxB

COMM

RxB

TxEN

RxA

Rx

RTS (PIN 6)

TxB (PIN 1)

COMM

Tx

COMM

CTS (PIN 1)

AUXILIARY

RS485 COMMS PORTCOMMS PORTPGM PORT

RS232 RS485 RS232

DEVICE

USB

POWER

-+ETHERNET

AUXILIARY

PORT B

RS485 USB HOST PORT A (PGM)

RS232

PORT B

RS232

PORT A

RS485

CONNECTOR

POWER

CHASSIS

COMMON

+DC VOLTAGE

1

2

3

[OPTIONAL]

[OPTIONAL]

A

BETHERNET

G15 PORT PIN OUTS

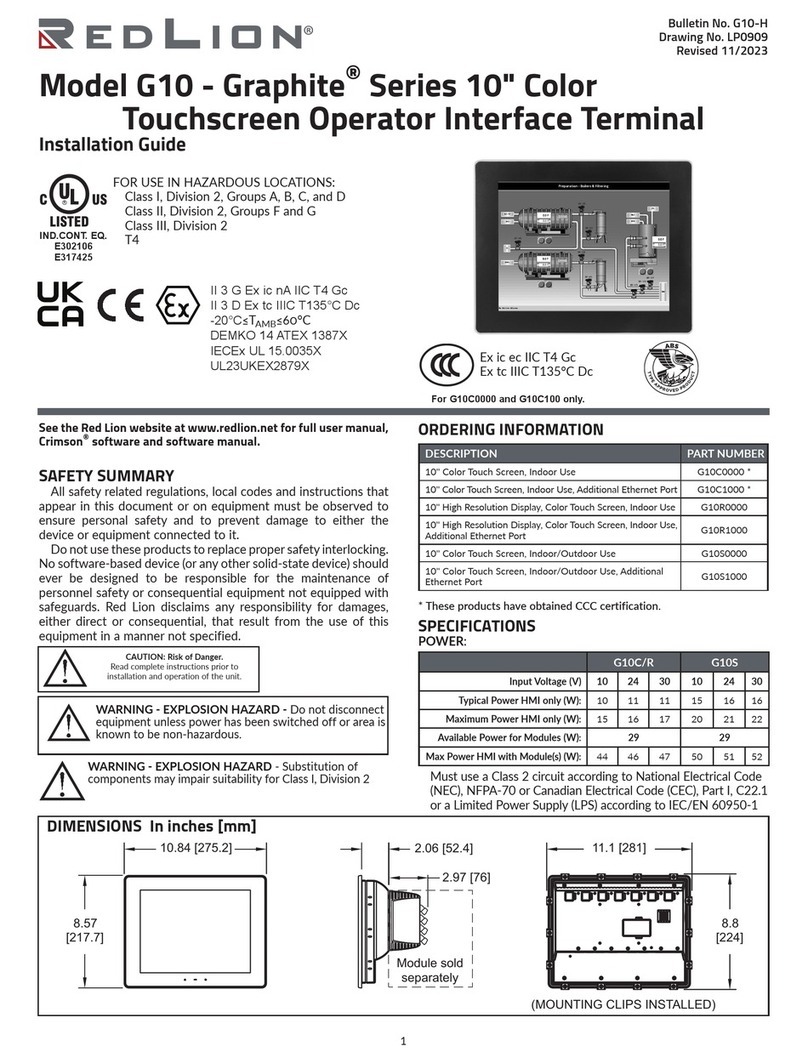

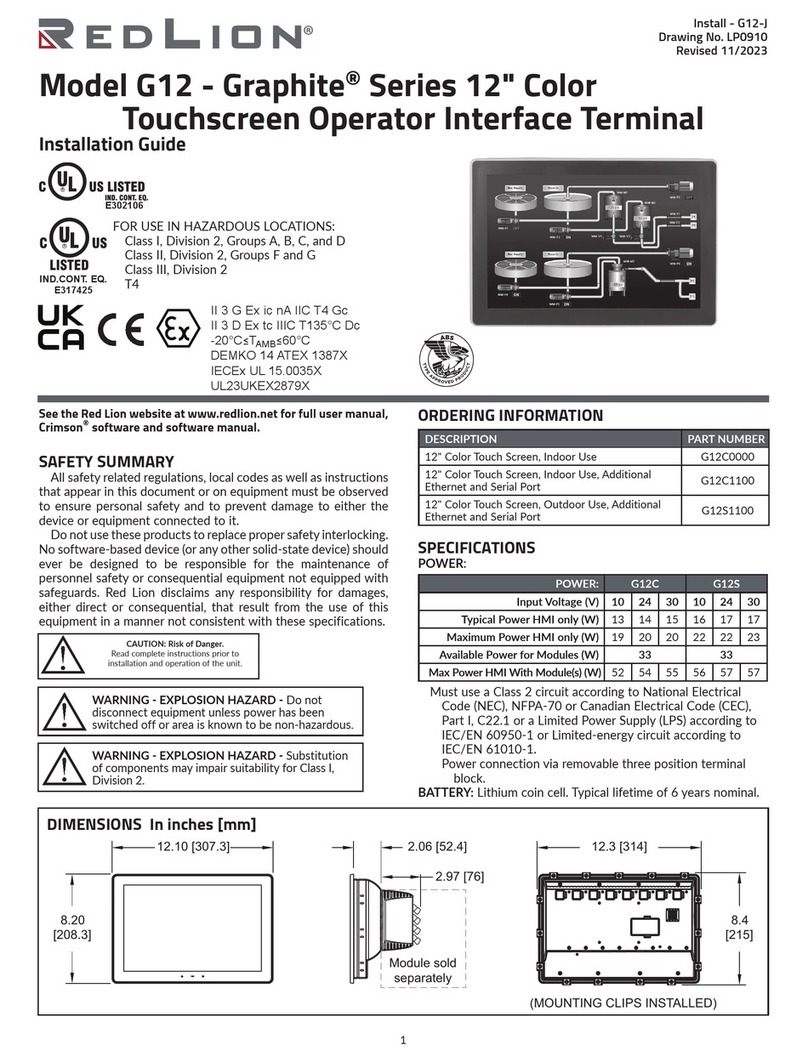

POWER SUPPLY REQUIREMENTS

The G15 requires a 10-30 VDC power supply. Your unit may

draw considerably less than the maximum rated power depending

upon the features being used. As additional features are used

your unit will draw increasing amounts of power. Items that could

cause increases in current are modules, additional on-board

communications, SD card, and other features programmed

through Crimson.

To ensure you do not exceed the capacity of your Graphite host

power supply, calculate the total power consumption required for

all of your planned modules. Each module’s maximum power

consumption is listed in the Specifications of their Product

Bulletin. The total power available for modules is listed in the

specifications of the Graphite host.

In any case, it is very important that the power supply is

mounted correctly if the unit is to operate reliably. Please take

care to observe the following points:

– The power supply must be mounted close to the unit, with

usually not more than 6 feet (1.8 m) of cable between the

supply and the operator interface. Ideally, the shortest

length possible should be used.

– The wire used to connect the operator interface’s power

supply should be at least 22-gage wire suitably rated for the

temperatures of the environment to which it is being

installed. If a longer cable run is used, a heavier gage wire

should be used. The routing of the cable should be kept

away from large contactors, inverters, and other devices

which may generate significant electrical noise.

– A power supply with an NEC Class 2 or Limited Power

Source (LPS) and SELV rating is to be used. This type of

power supply provides isolation to accessible circuits from

hazardous voltage levels generated by a mains power supply

due to single faults. SELV is an acronym for “safety extra-

low voltage.” Safety extra-low voltage circuits shall exhibit

voltages safe to touch both under normal operating

conditions and after a single fault, such as a breakdown of a

layer of basic insulation or after the failure of a single

component has occurred. A suitable disconnect device shall

be provided by the end user.