3

MAINTENANCE

1. INSPECTION:

Valves should occasionally be inspected for damage

and wear. The inspection period should be determined

by the severity of the service and environment. If valves

are periodically inspected and preventive maintenance

done, the valve will last longer and operate better.

CAUTION: Do not remove the bolting or valve parts

with pressure in the line. Relieve pressure on both

sides of the valve prior to servicing.

ELASTOMER MEMBRANE REPLACEMENT:

1. A spare replacement membrane should be placed on

order when this valve is placed in service.

2. Remove the existing valve and install the replacement

membrane by removing the rod fasteners and mount-

ing rod. Place the new membrane on the disc while

aligning mounting holes in membrane with holes in the

disc. The membrane must be placed on the disc with

the label facing you. Improper operation may result if

the membrane is installed with the label facing the disc.

Re-install rod, bolts and torque lock nuts just enough

for compression of rod to membrane to disc. Do not

over torque lock nuts as it may cause edge of mem-

brane to lift off disc.

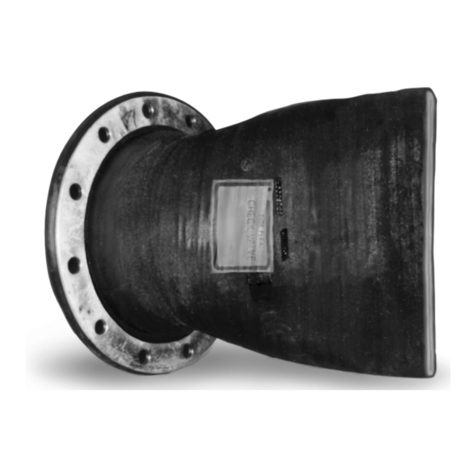

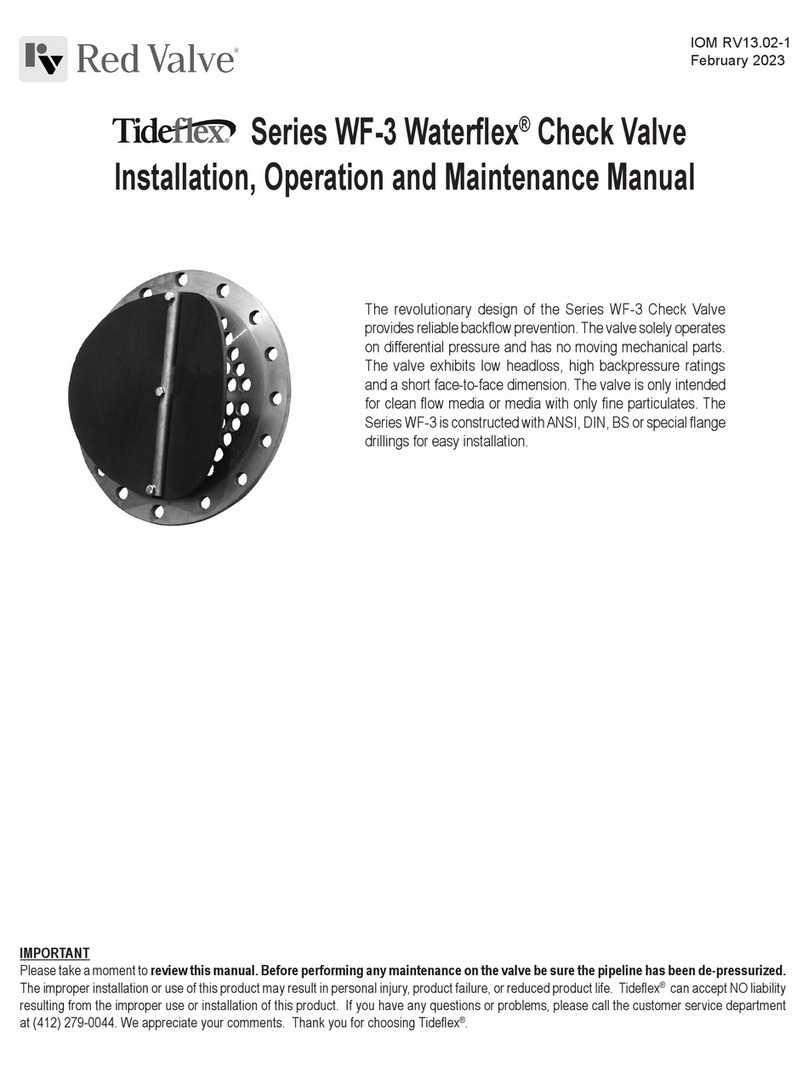

The Series WF-3 operates soley on differential

pressure. Positive differential opens the valve allow-

ing flow, reverse differential closes the valve prevent-

ing backflow.

The Series WF-3 Check Valve is a self containing

Check Valve with backpressure ratings shown in the

table on this page. Backpressures in excess of these

ratings can damage the disc or membrane.

Red Valve check valves are custom made products

intended for a specific application and have been

designed to respond to criteria unique to that pur-

pose, such as line pressure, minimum and maximum

backflow pressure, and chemical compatibility. Should

the conditions for which the valve has been designed

be altered or change in any way, it could affect the

normal operation of the valve.

OPERATION

If your Waterflex™ Valve is to be stored for a period

of time prior to installation, the following storage

guidelineswill help preserve yourvalve and assure a

trouble free installation.

1. Store valve in a clean, cool, dry location. Avoid

exposure to light, electric motors, dirt or chemicals.

2. Store valve to prevent other items from contacting

membrane or flanges to prevent possible damage.

3. Lay Waterflex™ flat with membrane up.

4. Store this manual with the valve, so that it is readily

available at time of installation.

STORAGE

Backpressure Ratings Table

Consult factory for larger sizes and higher working pressure.

Nominal ANSI BACK PRESSURE

PIPE FLANGE OUTSIDE ANSI RATING

SIZE SIZE DIAMETER psi

4

"

4" 9" 150

6

"

6" 11" 150

8

"

8" 13.5" 125

10

"

10" 16" 100

12

"

12" 19" 75

14

"

14" 21" 75

16

"

16" 23.5" 75

18

"

18" 25" 75

20

"

20" 27.5" 75

24

"

24" 32" 50

30

"

30" 38.75" 50

36

"

36" 46" 50

42

"

42" 53" 50

48

"

48" 59.50" 50