3

battery to spark or might short-circuit the battery or other

electrical parts that may cause an explosion.

12. Remove personal metal items such as rings, bracelets,

necklaces, and watches when working with batteries. A

battery can produce a short-circuit current high enough to

weld a ring or the like to metal, causing a severe burn.

A SPARK NEAR A BATTERY MAY CAUSE THE BATTERY

TO EXPLODE. TO REDUCE THE RISK OF A SPARK NEAR A

BATTERY WHEN CONNECTING THE BATTERY INSTALLED

IN A VEHICLE TO THE BATTERY CHARGER, ALWAYS DO

THE FOLLOWING:

Always wire the Output Connector before connecting it to the

Battery Charger. During connection of the unit, the Battery

Output (positive) must be connected first, followed by the

Ground (chassis) terminal. The chassis connection should

be made away from the battery and fuel lines. DC Input

(positive) should be connected last. Once all connections are

wired to the Output Connector, plug the connector into the

Main Unit.

When disconnecting the Battery Charger, remove the AC

Connector first, followed by the CAN connection then the

Output Connector from the Main Unit. The DC Input should

be disconnected next, followed by the Ground (chassis)

connection, then the Battery Output connection if complete

removal is necessary.

13. PERSONAL SAFETY PRECAUTIONS

To assist with the safe operation and use of the Battery

Charger:

a) Consider having someone close by to come to your aid when

you are using the Battery Charger.

b) Have plenty of fresh water and soap nearby in case battery

acid contacts skin, clothing, or eyes.

c) Wear complete eye protection and clothing protection. Avoid

touching eyes while working near a battery.

d) If battery acid contacts your skin or clothing, remove the

affected clothing and wash the affected area of your skin

immediately with soap and water. If battery acid enters your

eye, immediately flood the eye with running cold water for at

least 10 minutes and seek medical assistance immediately.

e) To improve user safety it is recommended to control the

charger and monitor the charging process using the remote

away from the vicinity of the battery being charged.

NOTICE

1. Do NOT connect computers or IT equipment to the Charger

front panel connector or remote. Damage may occur.

2. It is recommended to leave the remote connected to the

base unit at all times.

3. The Main Unit must be fixed using suitable screw

mounts. Failure to adequately mount the unit, such as

using adhesives to mount the unit will result in unreliable

operation of the charger.

4. When using the charger in Storage mode, make sure that

there is a valid charging source and that all loads are

disconnected from the house battery. Failure to do so may

cause the house battery to be under charged, give false

readings on the State of Charge indicator and possibly cause

damage to any loads connected.

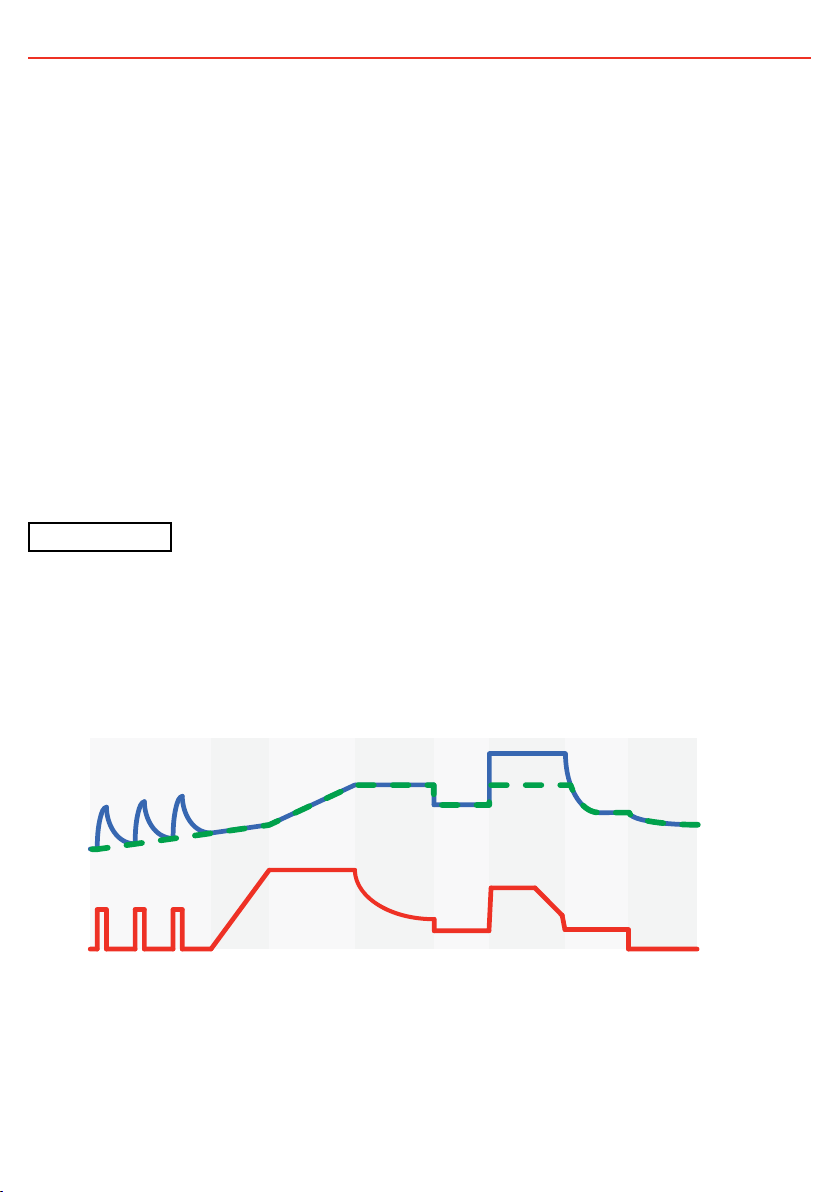

5. A partially shaded panel (or low-light conditions such as

dawn or dusk) will increase the target solar panel voltage

level to match the maximum power point. In this situation

solar will be selected as a source however little or no current

will be flowing into the battery.

6. Modification of the ‘Advanced Settings’ menu items affect

the way the Battery Charger responds to charging situations.

Modification of these settings may result in the Battery

Charger not functioning at 100% of its capacity. These

settings should only be modified if absolutely necessary and

when the effects of the changes are 100% understood.

7. Touring mode will achieve its best charge level if a Storage

mode charge has been recently performed.

8. It is the installers responsibility to ensure their installation

complies with any applicable legal and regulatory

requirements.

FCC DECLARATION

This device complies with part 15 of the FCC Rules. Operation

is subject to the following two conditions: (1) This device may

not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause

undesired operation.

Note: This equipment has been tested and found to comply

with the limits for a Class B digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of

the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician

for help.

WARNINGS AND SAFETY INSTRUCTIONS