1. Models designed for fuel are coded with the prefix “F” i.e., “FF9500 OLP.”

Check name plate on the reel before installing.

2. Do not use reel at higher pressures or temperatures than listed on the back

of this bulletin.

3. Remove all spring tension before beginning dissassembly process.

4. Reel spring motor case is permanently sealed. Any attempt to remove the

spring motor may cause serious injury.

SAFETY

INSTALLATION: The swivel union is packed separately in the reel carton, use teflon tape to assure a satisfactory seal. A flexible hose

connection must be used between the hose reel inlet and the source of supply to prevent possible misalignment and

binding. Non flexible connections will void the warranty, pressure rating of inlet hose must be equal to or more than

the pressure rating of the reel. Consult factory for proper spring when installing reels above 16 ft.

LUBRICATION: Hose reel spring and bearings are factory lubricated and require no further lubrication.

REPLACING HOSE: 1. Wind spool flange clockwise-facing swivel-until spring is tight.

2. Back off three turns and latch.

3. Insert hose through roller guide.

4. Connect hose fitting to female outlet ell.

ADJUSTMENTS: To adjust spring tension, add or remove wraps of hose from the spool, one wrap at a time until desired tension is

obtained.

REPAIRS: Extensive repairs should be performed only by an authorized serviceman or factory to avoid damage which may

void your warranty. Remove all spring tension before beginning disassembly process.

MODIFICATION: Hose latching mechanism can be removed for constant tension applications.

FF9500 OLPBW FF9600 OLPBW

Operating Instructions

Series FF9000 Spring Driven Hose Reels

Low Pressure Model Numbers:

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

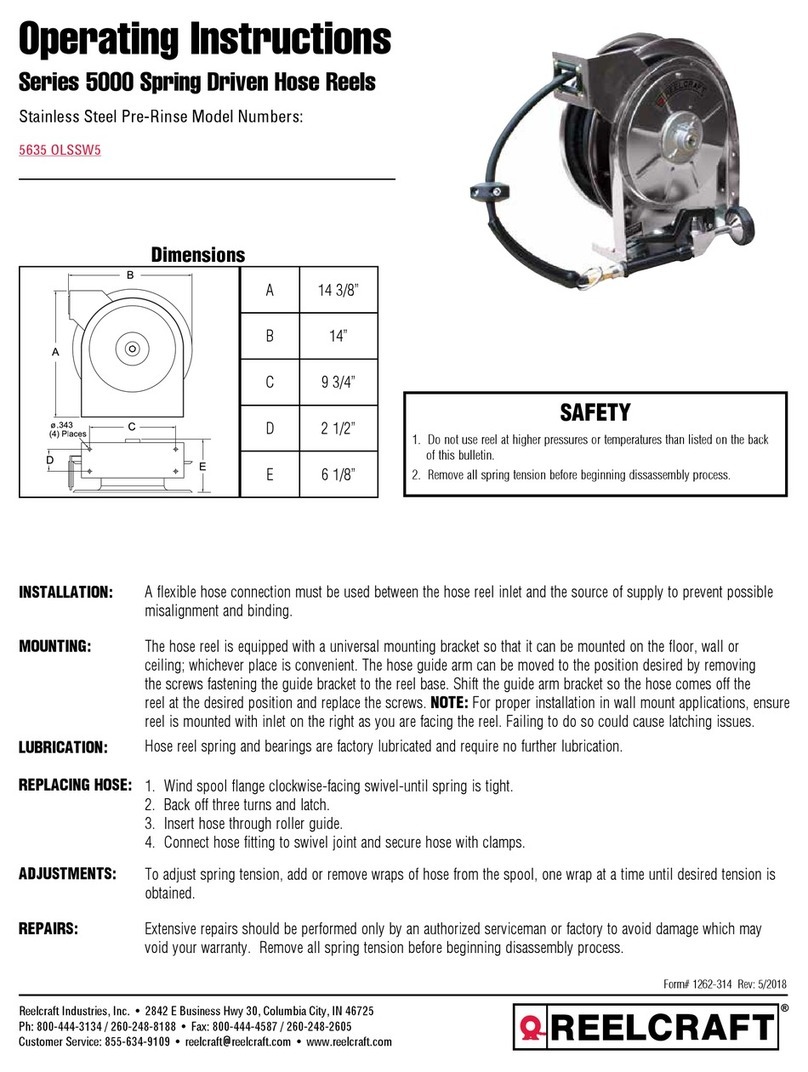

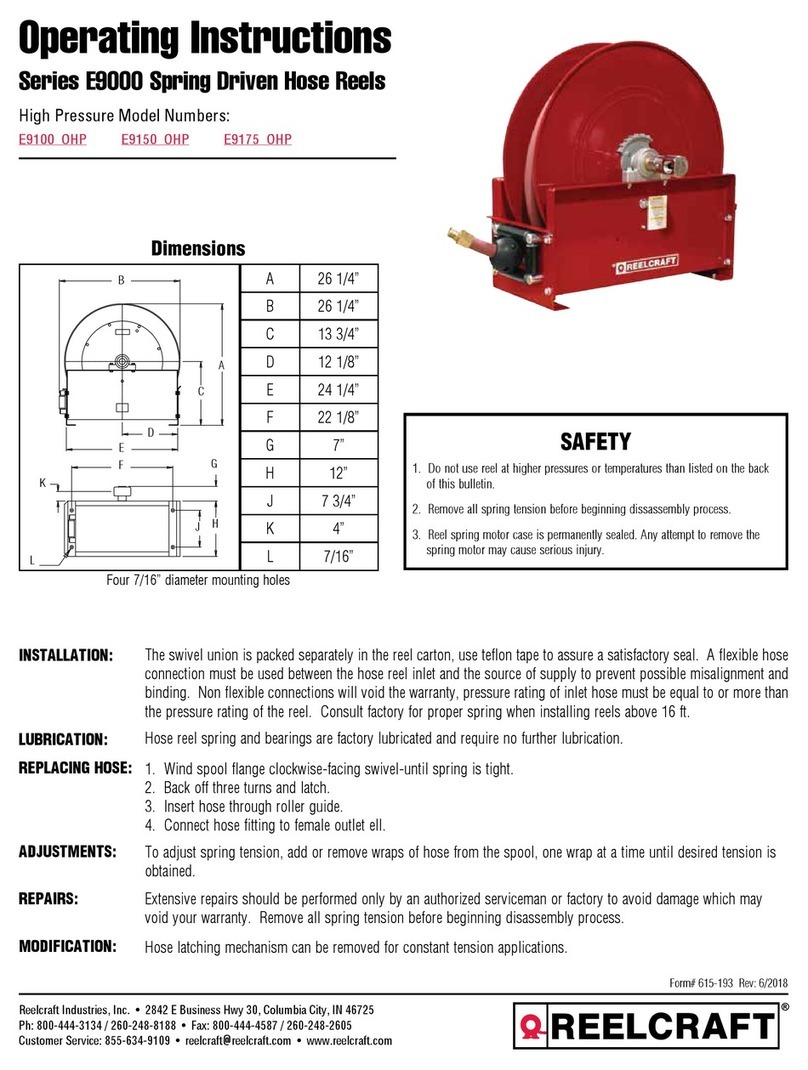

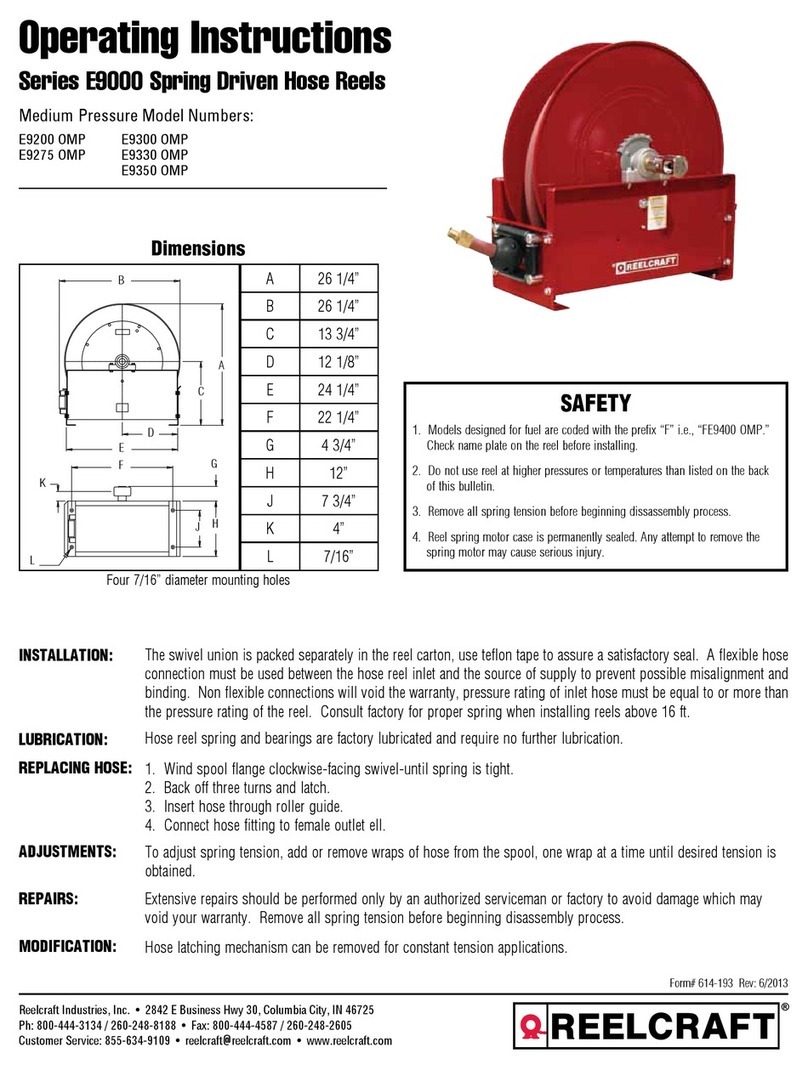

A26 3/8”

B26 1/4”

C22 1/4”

D13 1/2”

E17 3/4”

F24 1/8”

G3 7/8”

Dimensions

Form# 1152-204 Rev: 6/2018

A

B

C

DE

G

F