8540581 - 29/09/2010 - Rev.10 1

PHOTOELECTRIC

SAFETY

BARRIER

ADMIRAL AX BK

INSTALLATION USE AND MAINTENANCE

INDICE

INTRODUCTION..................................................................................................................... 2

OPERATION............................................................................................................................ 3

INSTALLATION....................................................................................................................... 4

POSITION..................................................................................................................................... 5

MASTER/SLAVE POSITIONING.................................................................................................. 6

SAFETY DISTANCE CALCULATION........................................................................................... 7

VERTICAL POSITION OF THE BARRIER................................................................................... 8

HORIZONTAL POSITION OF THE BARRIER ............................................................................. 9

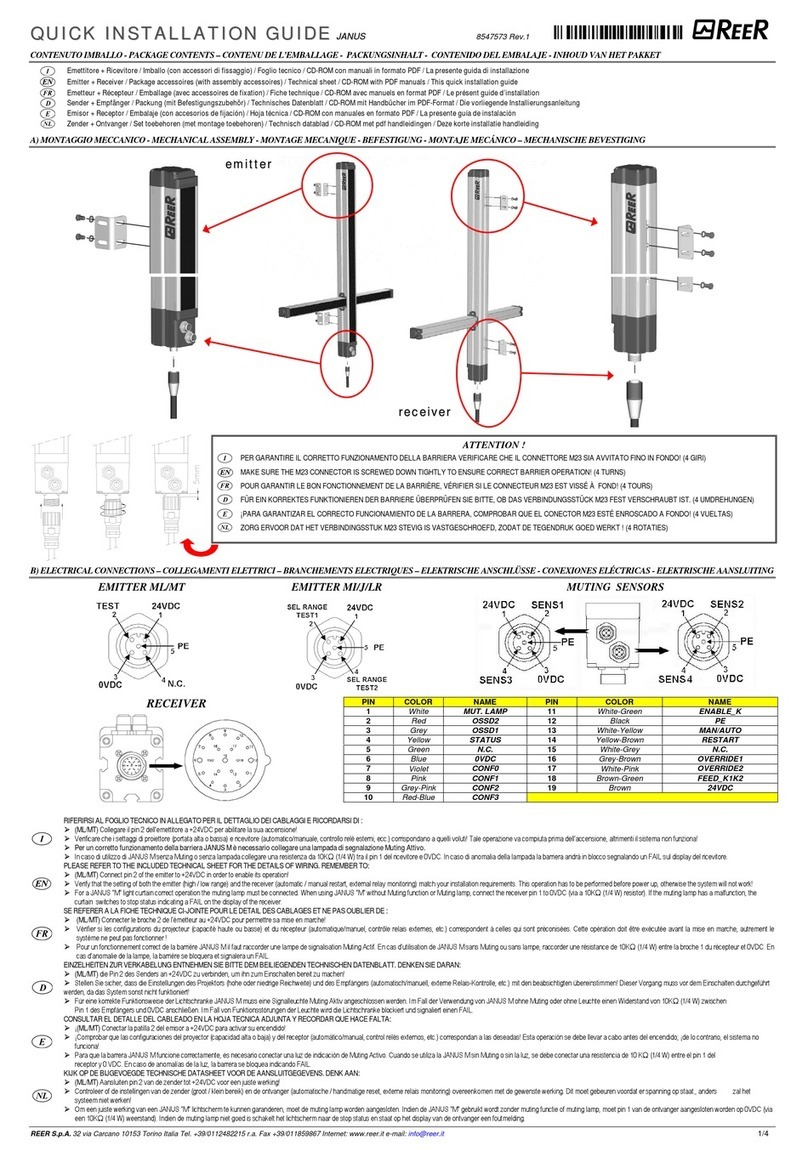

ELECTRICAL CONNECTIONS.................................................................................................. 10

EMITTER CONNECTIONS......................................................................................................... 11

RECEIVER CONNECTIONS...................................................................................................... 11

WARNINGS REGARDING THE CONNECTION CABLES......................................................... 12

BLANKING FUNCTION .............................................................................................................. 13

CONFIGURATION OF THE TYPE OF BLANKING.................................................................... 18

MULTIPLE SYSTEMS ................................................................................................................25

USE OF DEFLECTION MIRRORS............................................................................................. 26

DISTANCE BETWEEN REFLECTING SURFACES .................................................................. 27

MECHANICAL ASSEMBLY AND OPTICAL ALIGNMENT......................................................... 28

OPERATION AND TECHNICAL DATA................................................................................. 29

SIGNALS..................................................................................................................................... 29

TEST FUNCTION ....................................................................................................................... 31

OUTPUT STATUS...................................................................................................................... 31

TECHNICAL SPECIFICATIONS................................................................................................. 32

DIMENSIONS........................................................................................................................ 33

CHECKOUTS AND MAINTENANCE.......................................................................................... 34

TROUBLESHOOTING................................................................................................................ 36

SPARE PARTS...................................................................................................................... 39

GUARANTEE ........................................................................................................................ 40