Positioning ...................................................................................................... 6

Master/Slave Positioning.................................................................................. 7

Calculation of safety distance .......................................................................... 8

Multiple systems ............................................................................................. 9

Use of deflecting mirrors ............................................................................... 10

Distance from reflective surfaces ................................................................... 11

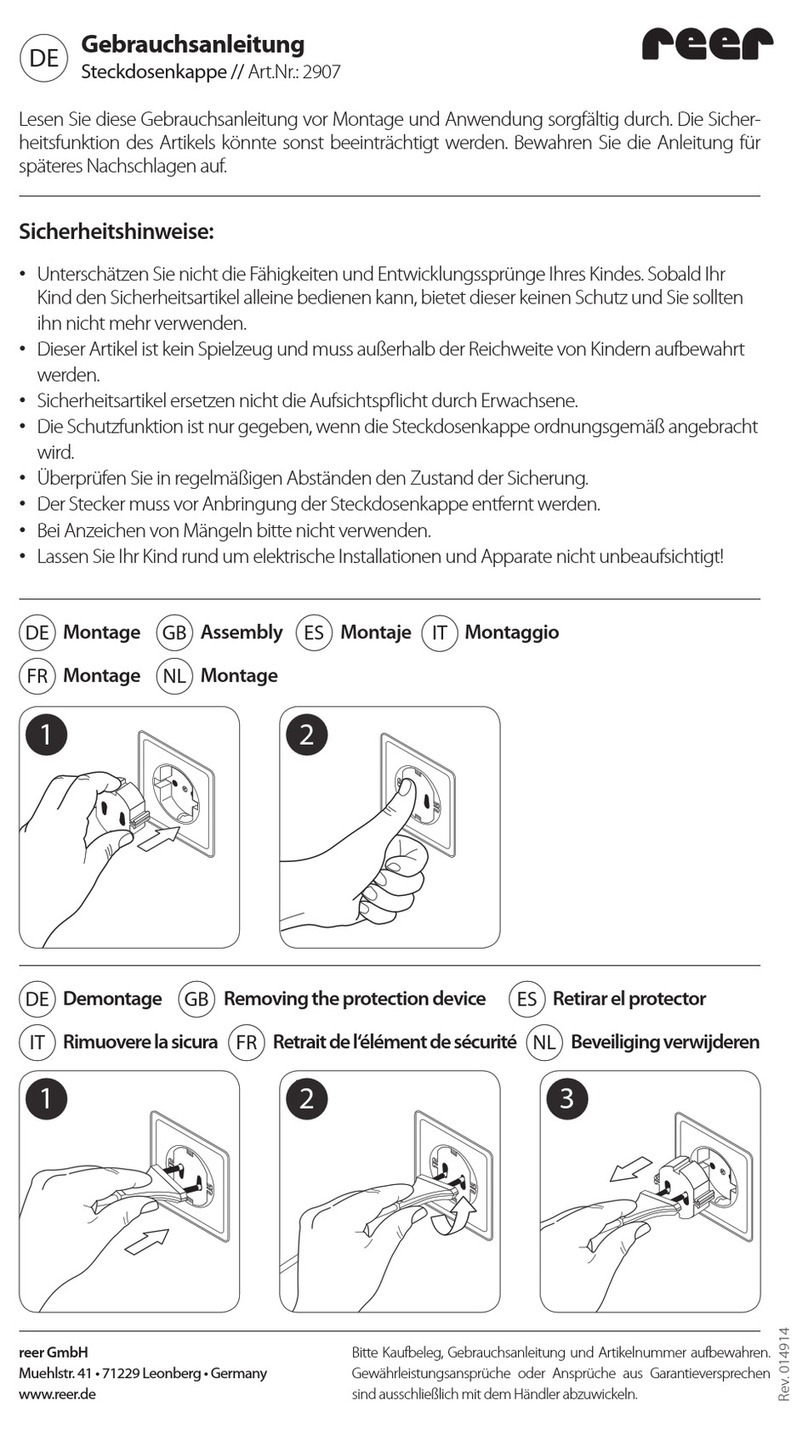

Mechanical assembly and optical alignment ................................................... 12

Vertical positioning of the light curtain .......................................................... 13

Models with 14, 20mm resolution............................................................... 13

Models with 30, 40mm resolution............................................................... 13

Models with 50, 90mm resolution............................................................... 13

Multibeam Models ...................................................................................... 14

Horizontal positioning of the light curtain...................................................... 14

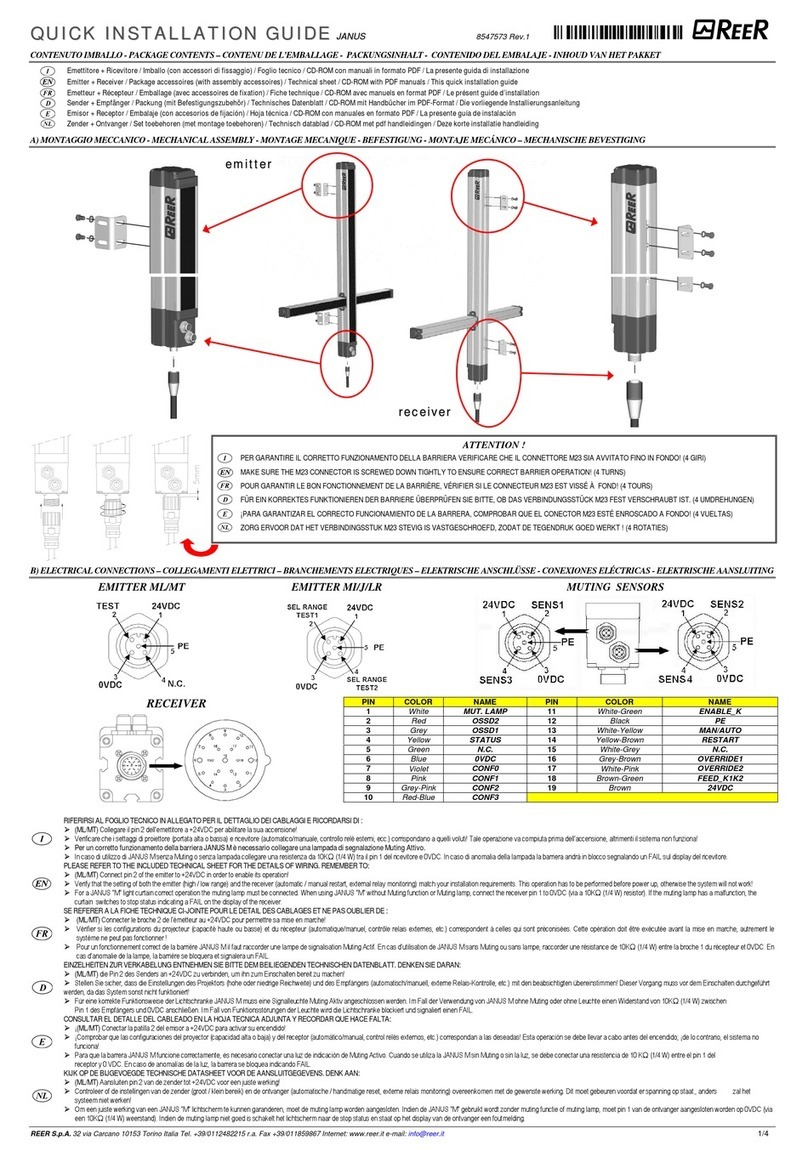

Electrical connections .................................................................................... 15

Layout of the connectors on MASTER/SLAVE light curtain ............................ 15

Emitter connections.................................................................................... 16

Receiver connections .................................................................................. 17

Warnings regarding connection cables........................................................ 18

Configuration and operating modes (Master Models / With integrated control

functions)...................................................................................................... 19

Automatic operation................................................................................... 19

Manual operation ....................................................................................... 19

Connection of external contactors K1 and K2.............................................. 20

Examples of connection with REER safety modules...................................... 21

Light signals.................................................................................................. 24

Emitter light signals ................................................................................... 24

Receiver light signals.................................................................................. 24

TEST function ................................................................................................ 25

Status of the outputs ..................................................................................... 25

Technical specifications................................................................................. 26

Dimensions ................................................................................................... 31

Checking of light curtain efficiency ................................................................ 33

Troubleshooting............................................................................................ 34

Accessories/Spares........................................................................................ 36