TYPE 4 SAFETY LIGHT CURTAIN

JANUS

SUMMARY

INTRODUCTION ............................................................................................................................................... 3

PRINCIPLE OF OPERATION........................................................................................................................... 4

LIGHT CURTAIN............................................................................................................................................ 4

MUTING FUNCTION ..................................................................................................................................... 5

SERIES "ML" - PREASSEMBLED KIT OF JANUS LIGHT CURTAIN AND SENSOR ELEMENT “Ml

S” Integrated Muting sensors –only for one-way openings with pallet exit......................................... 5

SERIES "MT" - KIT PREASSEMBLED OF JANUS LIGHT CURTAIN AND SENSORS ELEMENTS

“MT SI” and “MT SE” Integrated Muting sensors – for two-way openings with pallet entrance/exit. .. 6

SERIES "MT S4" - KIT PREASSEMBLED OF JANUS LIGHT CURTAIN AND SENSORS

ELEMENTS “MT S” Integrated Muting sensors – for two-way openings with pallet entrance/exit. .... 6

SERIES "ML S2" - KIT PREASSEMBLED OF JANUS LIGHT CURTAIN AND SENSORS

ELEMENTS “ML S” Integrated Muting sensors – for one-way openings with pallet exit. ................... 7

MODEL "MI" –external sensors 3 selectable methods of Muting....................................................... 7

MI models used with “l” operational logic.............................................................................................. 9

INSTALLATION ................................................................................................................................................ 9

POSITIONING.............................................................................................................................................. 11

POSITIONING OF THE MUTING SENSORS ("MI" SERIES)............................................................ 11

POSITIONING AND ADJUSTMENT OF SENSOR ELEMENTS FOR "ML" and "MT" SERIES:...... 13

CALCULATION OF THE SAFETY DISTANCE.................................................................................. 14

VERTICAL POSITIONING OF THE LIGHT CURTAIN....................................................................... 15

MULTIPLE SYSTEMS........................................................................................................................ 17

DISTANCE FROM REFLECTIVE SURFACES.................................................................................. 17

LIGHT SIGNALS.......................................................................................................................................... 19

Emitter SIGNALS................................................................................................................................ 19

Receiver SIGNALS............................................................................................................................. 20

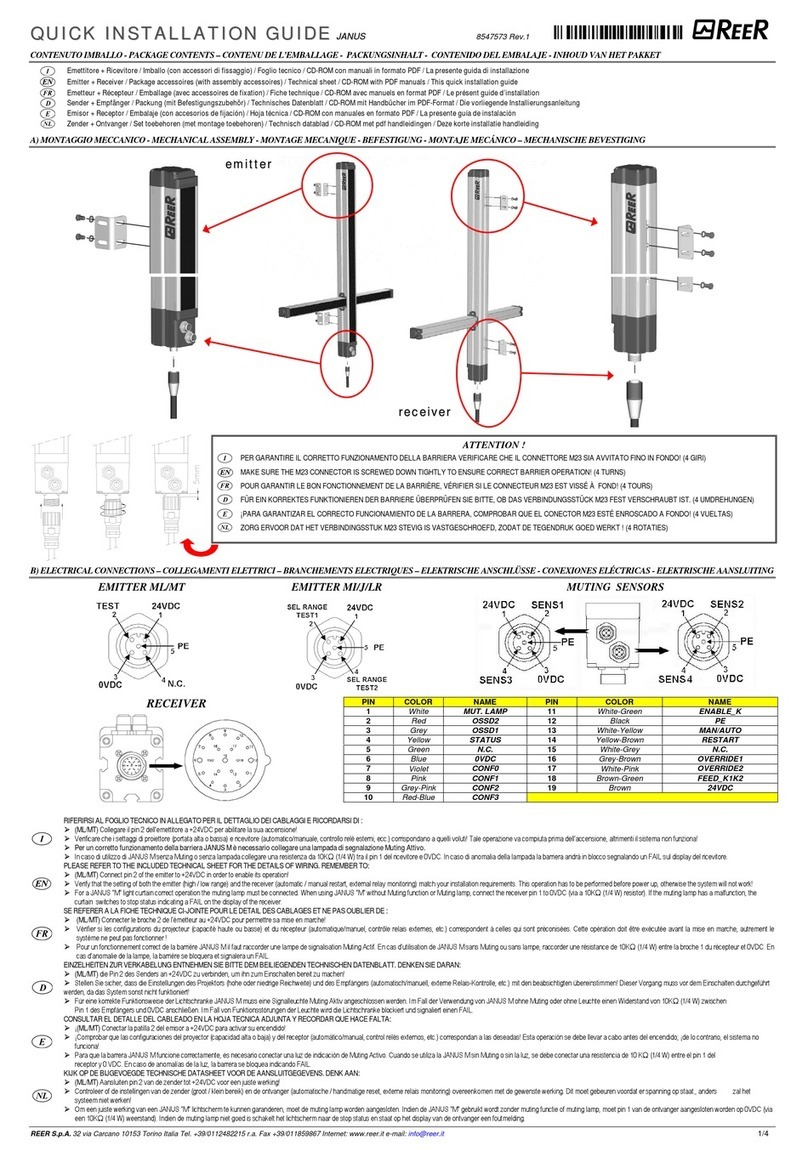

ELECTRICAL CONNECTIONS AND CONNECTORS................................................................................ 22

EMITTER Connections (Male Connector)......................................................................................... 22

RECEIVER CONNECTIONS (Main Connector - Male)...................................................................... 23

Connections CONNECTOR M12 n. 1 (for muting sensor) ("MI" MODELS) (Female Connector)...... 24

Connections CONNECTOR M12 n. 2 (for muting sensor) ("MI" MODELS) (Female Connector)..... 24

RECEIVER CONNECTIONS J LR M12 MODELS............................................................................. 25

SELECTION OF CONFIGURATION AND OPERATING MODE................................................................. 25

SELECTION FEEDBACK EXTERNAL CONTACTORS K1/K2.......................................................... 25

SELECTION OF MANUAL/AUTOMATIC FUNCTIONING................................................................. 26

SELECTION OF THE MAXIMUM DURATION AND TYPE OF MUTING .......................................... 27

OVERRIDE CONFIGURATION.......................................................................................................... 27

MUTING OVERRIDE FUNCTION (“M” MODELS) ............................................................................. 28

"SYSTEM STATUS" OUTPUT (“M” MODELS) .................................................................................. 29

TEST FUNCTION............................................................................................................................... 29

SAFETY MODULES MJB1 - MJB2 - MJB3 - MJB4 ........................................................................... 29

EXAMPLE OF CONNECTION WITH EXTERNAL CONTACTORS K1/K2 WITH start/restart interlock

activated.............................................................................................................................................. 30

EXAMPLE OF CONNECTION WITH AD SR0 WITH start/restart interlock activated....................... 31

MUTING STATUS AND LIGHT ("M" MODELS).............................................................................. 31

CONFIGURATION AND OPERATION MODES J LR M12......................................................................... 32

AUTOMATICO MODE........................................................................................................................ 32

MANUAL MODE................................................................................................................................. 33