Fillcontrol Plus — 06.07.2016 - Rev. B English —

English

FillcontrolPlus

06.07.2016-Rev. B

Contents

1Notes on the operating manual.....................................................................................................................................................5

2Liability and guarantee...................................................................................................................................................................5

3Safety................................................................................................................................................................................................6

3.1 Explanation of symbols........................................................................................................................................................................6

3.1.1 Symbols and notes used...................................................................................................................................................6

3.2 Personnel requirements ......................................................................................................................................................................7

3.3 Personal protective equipment..........................................................................................................................................................7

3.4 Intended use..........................................................................................................................................................................................7

3.5 Inadmissible operating conditions.....................................................................................................................................................7

3.6 Residual risks .........................................................................................................................................................................................8

4Description of the device................................................................................................................................................................9

4.1 Description.............................................................................................................................................................................................9

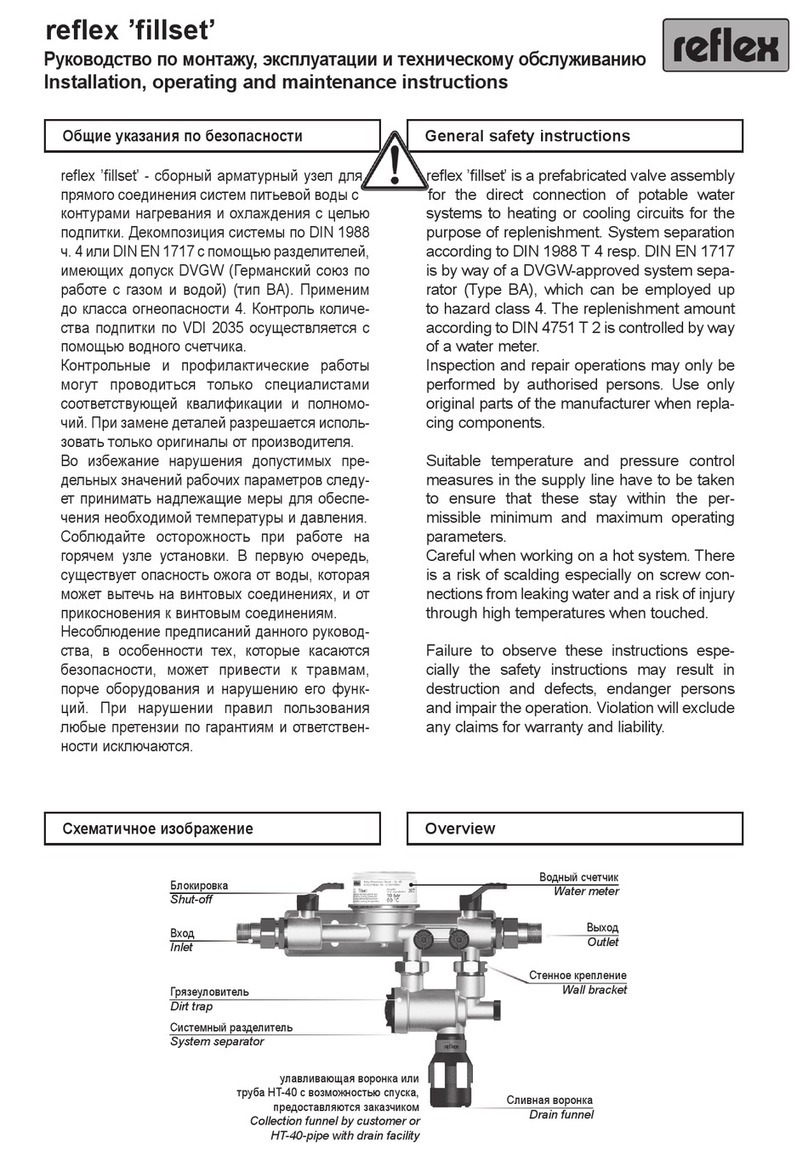

4.2 Overview ................................................................................................................................................................................................9

4.3 Identification .......................................................................................................................................................................................10

4.3.1 Nameplate ........................................................................................................................................................................10

4.3.2 Type code..........................................................................................................................................................................10

4.4 Function ...............................................................................................................................................................................................11

4.5 Scope of delivery.................................................................................................................................................................................12

4.6 Optional equipment and accessories ..............................................................................................................................................12

5Technical data ...............................................................................................................................................................................13

5.1 Electrical system..................................................................................................................................................................................13

5.2 Dimensions and connections............................................................................................................................................................13

5.3 Operation .............................................................................................................................................................................................13

6Installation.....................................................................................................................................................................................14

6.1 Installation conditions .......................................................................................................................................................................15

6.1.1 Incoming inspection .......................................................................................................................................................15

6.2Preparatory work ................................................................................................................................................................................15

6.3 Execution..............................................................................................................................................................................................16

6.3.1 Wall mounting .................................................................................................................................................................16

6.3.2 Hydraulic connection......................................................................................................................................................17

6.4 Switching and make-up variants......................................................................................................................................................18

6.5 Electrical connection ..........................................................................................................................................................................20

6.5.1 Terminal diagram ............................................................................................................................................................21

6.5.2 RS-485 interface...............................................................................................................................................................23

6.6 Installation and commissioning certificate.....................................................................................................................................23

7Commissioning..............................................................................................................................................................................24

7.1 Requirements for initial commissioning .........................................................................................................................................24

7.2 Determining the P0minimum operating pressure for the controller.........................................................................................24

7.3 Filling the device with water.............................................................................................................................................................25

7.4 Parametrising the controller in the Customer menu ....................................................................................................................25

7.5 Function test........................................................................................................................................................................................25

7.6 Use the device to fill the facility system with water ......................................................................................................................26

7.7 Starting Automatic mode..................................................................................................................................................................26

8Operation.......................................................................................................................................................................................27

8.1 Operating modes ................................................................................................................................................................................27

8.1.1 Automatic mode..............................................................................................................................................................27

8.1.2 Manual mode ...................................................................................................................................................................27