TCF Fellbach (2021).0703/21

VP60 Analogue / IO-Link

Our policy is one of continued research and development. We therefore reserve the right

to amend, without notice, the speciications given in this document.

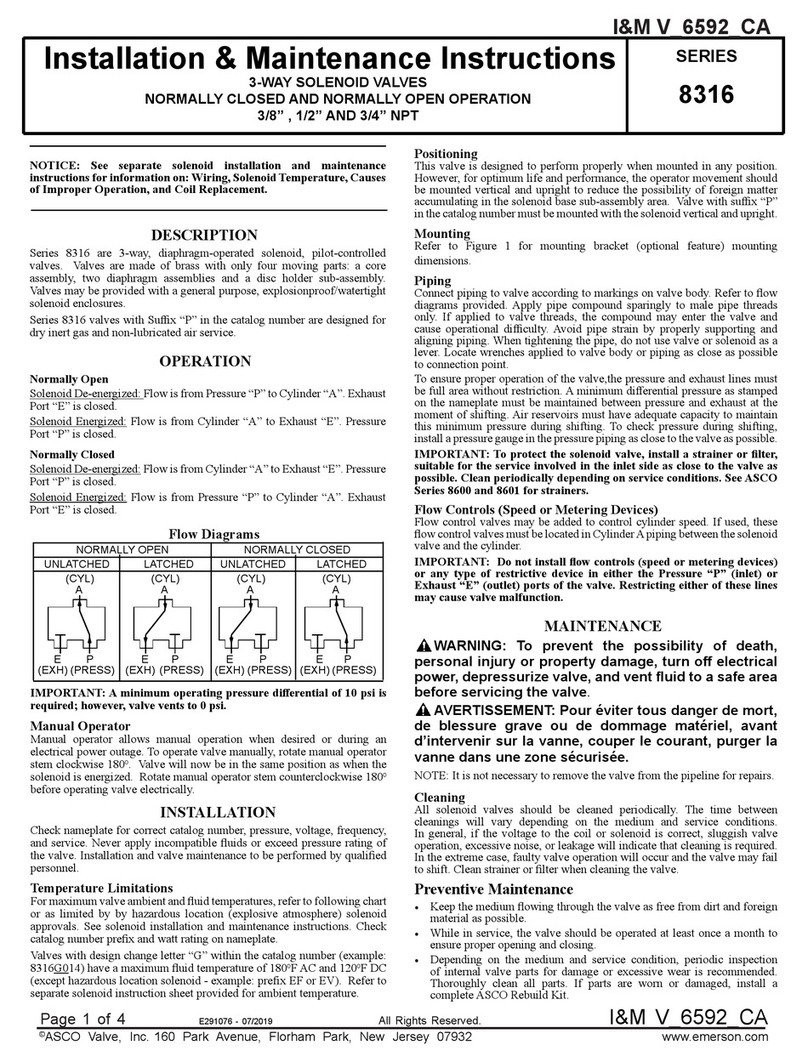

Filtered compressed air (see technical features) is available at port 1.

The actuator (2.e. cylinder) is connected to ports 2 and 4. Ports 3 and 5 are used for venting. Silencers with low low resistance

should be connected here.

The reaction of the actuator (e.g.: retraction or extension of a cylinder) in the event of a fault (e.g. power failure) results from

the connection diagram of the same to VP60 ports 2 and 4.

If no movement is desired in the event of a fault (see operating states of the valve), the responsible system designer should

provide additional shut-off valves between the valve and actuator.

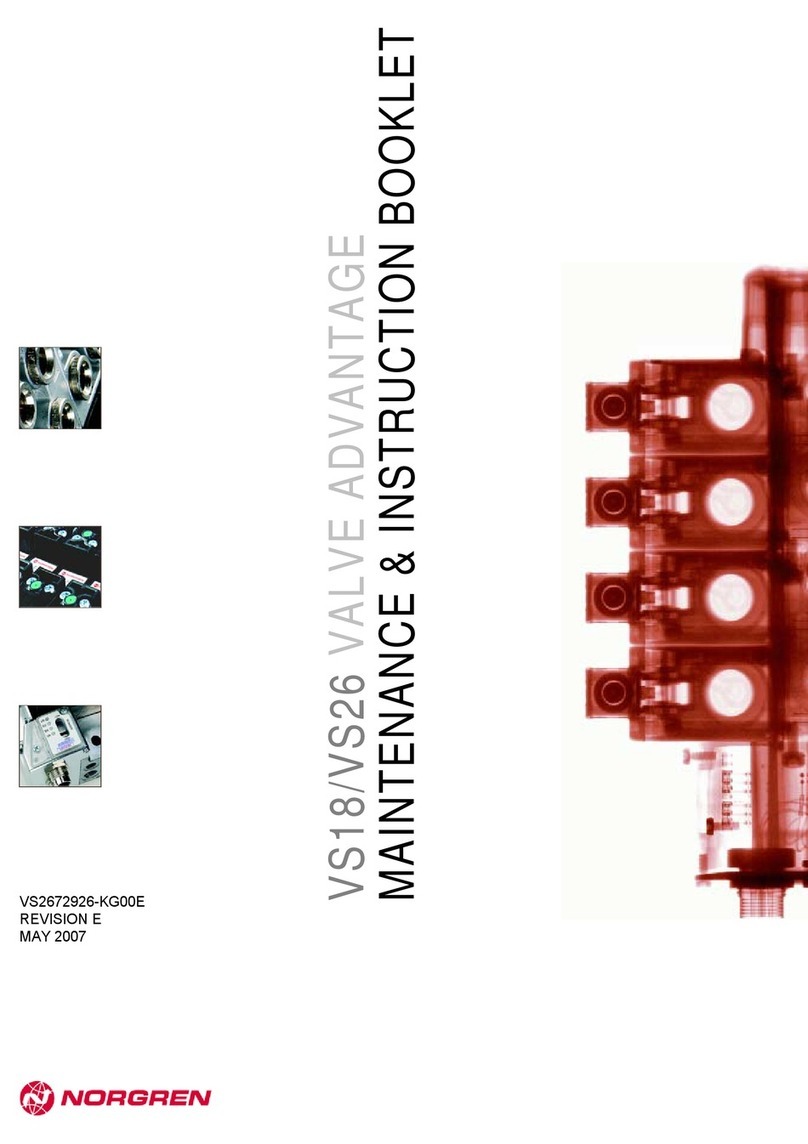

For consumers with constant air low, which require only one supply connection and no venting (e.g.: nozzles or turbines). The

following sub-functions result:

2/2 NC (normally closed): The air is connected to port 2. ports 3, 4 and 5 are closed.

Via VP-Tool*, the entire setpoint range can be assigned to the 2/2 valve function with the effect of (opening/closing). If this is

not done, the VP60 remains closed below the center. An exhausting effect can be adjusted above the middle. Middle = too,

max. Set point = max. Flow

2/2 NO (normally open): The air is connected to connection 4. connections 2,3 and 5 are closed.

Via VP-Tool*, the entire setpoint range can be assigned to the 2/2 valve function with any effect (opening/closing). If this is

not done, the VP60 remains closed above the middle. An exhaust effect can be set below the middle. min. Input=max. Flow,

Middle=to.

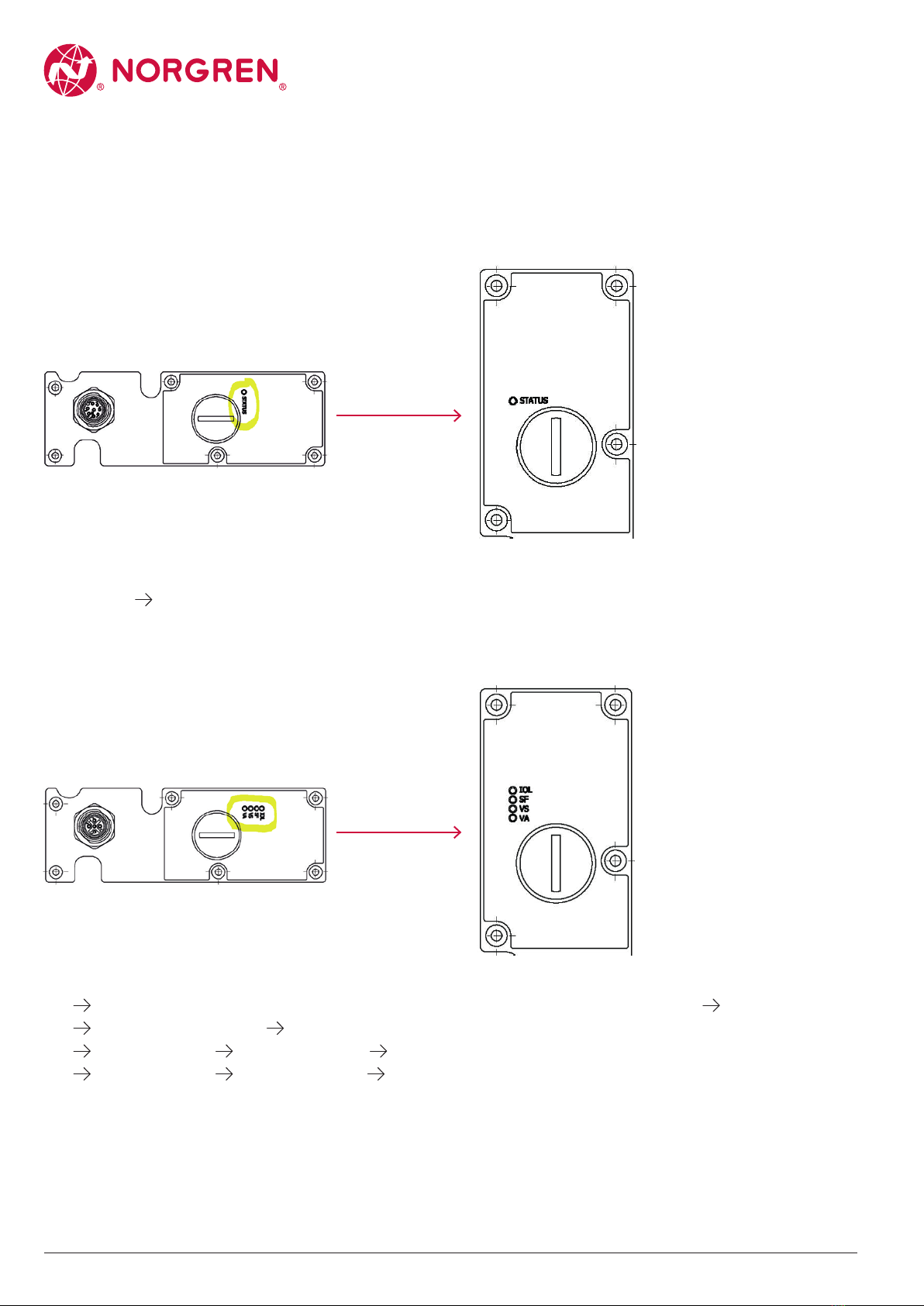

4.3.1. Function Type (5/3-way)

4.3.2. Function Type (2/2-way)

Note:

The accuracy of the valve remains unchanged by the use of the 2/2-way mode, which is only used for adaptation to

the conditions and the purpose of use in your plant.

*) In the IO-Link version, the function type must be set via the parameters described in the IODD. Details can also be

found in the parameter description list in the appendix.