4

Regal, Evergreen and Genteq are trademarks of Regal Beloit Corporation or one of its affiliated companies.

©2017, 2019 Regal Beloit Corporation, All Rights Reserved. MCIM19028E • Form G0038E • Printed in USA

Specifications:

Voltage: 208-230 (allowable voltage range 196-264) VAC, single-phase

input, 50-60 Hz

Horsepower:

• 1/5 HP (replaces 1/10-1/5)

• 1/3 HP (replaces 1/10-1/3)

Speeds: 2 operating speeds (Constant Speed)

• 1100 RPM (6-pole) replaces motors rated 1000-1100 RPM

• 850 RPM (8-pole) replaces motors rated 800-850 RPM

Rotation: CCW or CW by reversing plug or quick connect terminals

(factory set to CCW)

• As viewed from lead end

Bearing: Permanently lubricated ball bearing

Ambient Rating: 60° C

Enclosure: Totally Enclosed Air Over (TEAO), NEMA®48-frame

Shaft:

• 6301 & 6303 - Single, 1/2” diameter, 3” length, 2.5” single flat

• 6303R - Single, 1/2” diameter, 5.5” length, 5” single flat

Mounting:

• 6301 & 6303 - Horizontal or vertical shaft-down (VSD), belly band

or extended clamp bolts.

• 6303R - All angle mount with extended clamp bolts, OEM side or

rear mounting holes or belly band.

Leads: 54” length with ¼” fast on terminals, ground wire #10 eyelet

UL and CSA recognized component

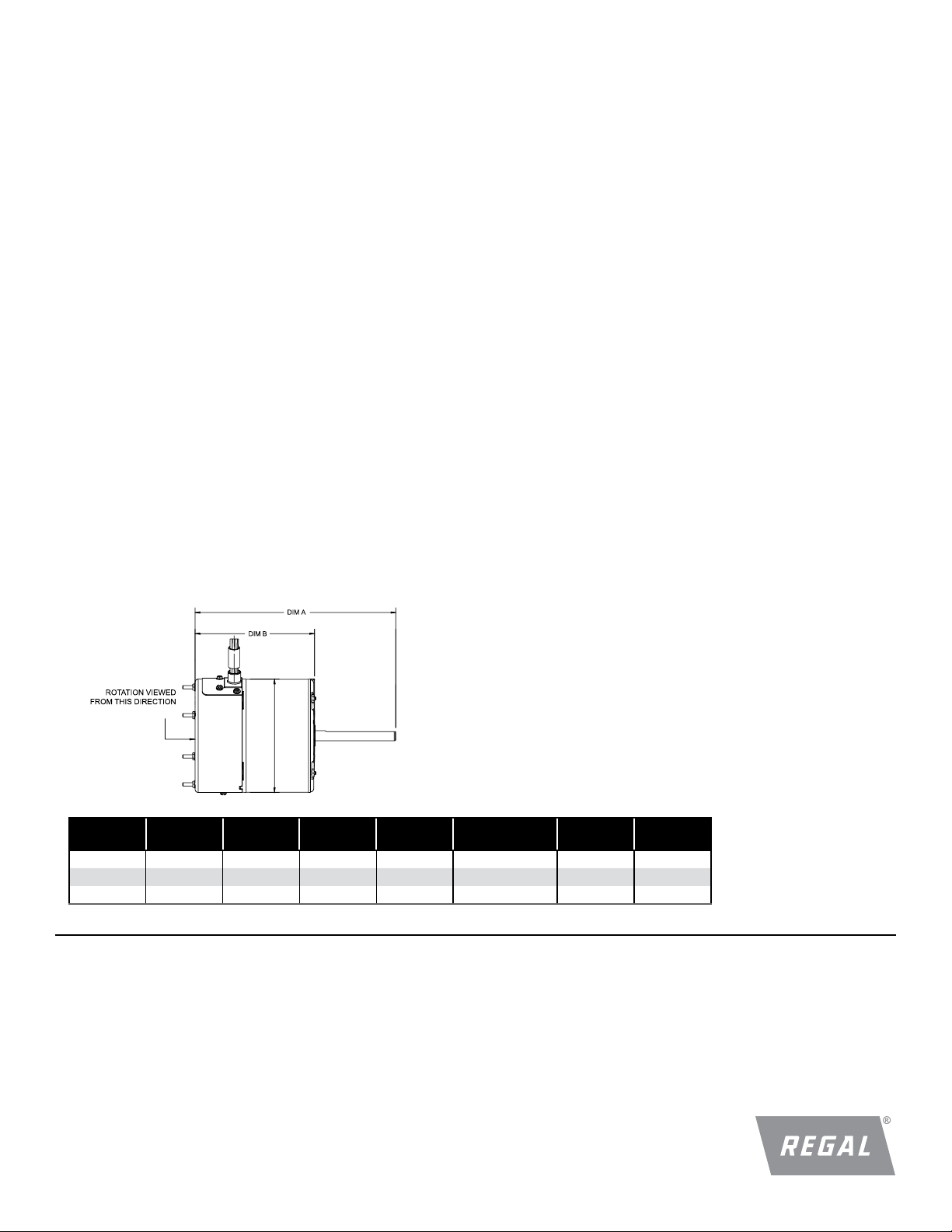

STOCK

NO. HP VOLTS MAX

CURRENT RPM SHAFT DIM A DIM B

6301 1/5 - 1/10 208-230 2.8 850/1100 .5” x 3” (2.5” SF) 8.49” 5.45”

6303 1/3 - 1/10 208-230 3.5 850/1100 .5” x 3” (2.5” SF) 8.99” 5.95”

6303R 1/3 - 1/10 208-230 3.5 850/1100 .5” x 5.5” (5” SF) 9.79” 4.23” *

* This dimension represents the motor length from end shield to end shield excluding control.

Application Note:

This product is designed to replace induction motors (shaded pole

or PSC) in direct-drive fan propeller applications. Do not use this

motor to replace OEM ECM outdoor fan motors or belt drive mo-

tors. OEM ECM outdoor fan motors must be replaced with OEM

equivalent.

The constant speed programming in this motor is what gives it the

ability to replace a range of horsepower ratings with one speed

selection.The speed selection provides the motor with an RPM

operating point.The motor then uses only the torque (amperage)

necessary to achieve this RPM operating point based on the size of

the fan blade (load). To accomplish this the motor constantly moni-

tors its operating speed RPM in real time.

Operation Note:

The Evergreen OM motor will delay turning on approximately 5 seconds

after L1 or L2 voltage is applied to one of the speed wires, then ramp

up to speed. The Orange and Yellow speed wires dictate the on/off

command to the motor control.

Technical Support:

If the motor does not operate with proper Line Voltage measured

between the White wire and the Black wire, AND between the White

wire and the Speed Selection, it has failed and will require replacement.

Before replacing the motor, please call the Contractor Hotline (1-866-

503-8566) to confirm your diagnostics if possible.

We will only provide support for Evergreen products to trained and

qualified service technicians familiar with the Evergreen OM motor and

the HVAC systems into which it will be installed. Technical support will

only be provided related to the proper operation of the Evergreen OM

motor.

The Evergreen OM motor is a single component replacement.The

control cannot be replaced separately from the motor. Contact the

distributor where the motor was purchased or any authorized Evergreen

motor distributor for replacement.

Evergreen®OM Models 6301, 6303 & 6303R (Remote Mount)

NEMA is believed to be the trademark and/or trade name of National Electrical Manufacturers Association

and is not owned or controlled by Regal Beloit Corporation.

Terms & Conditions of Sale & Limited Warranty

Sales of the products described in this Installation Manual are subject to the “Regal Beloit Terms and Conditions of Sale” current at the time of sale. They are accessible on

RegalBeloit.com – https://www.regalbeloit.com (click “Regal Terms and Conditions of Sale”).

The full Limited Warranty, including the scope and period, remedies, exclusions and disclaimers, is described in Section 10 “Limited Warranty” of the Regal Terms and

Conditions of Sale and applies except as described below:

Section 10(a)(1) is replaced with the following: Seller warrants that the Products shall be delivered free from defects in material, workmanship and title. This warranty

shall expire twenty-four (24) months from first use of the Product or thirty (30) months from date of manufacture of the Product, whichever occurs first.