INDEX

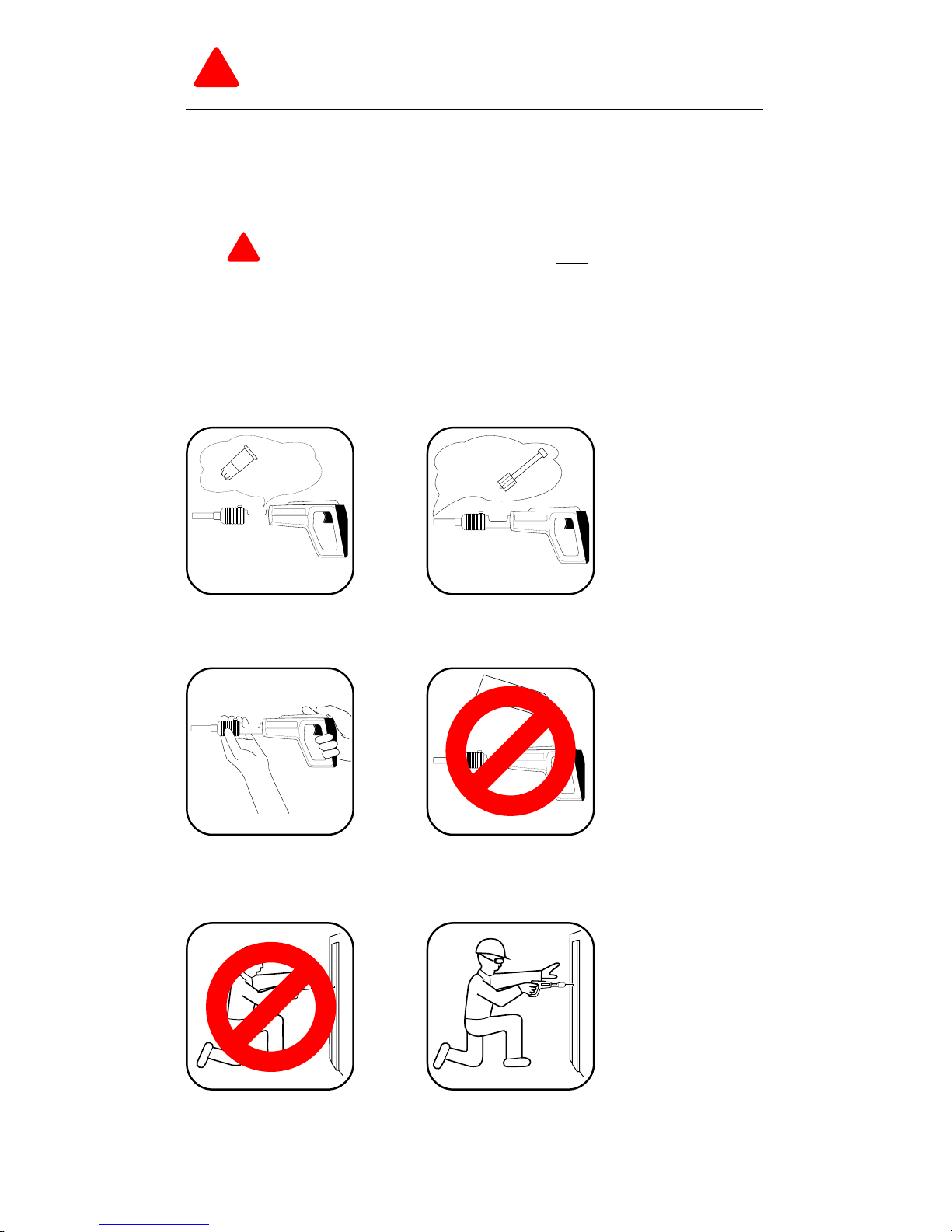

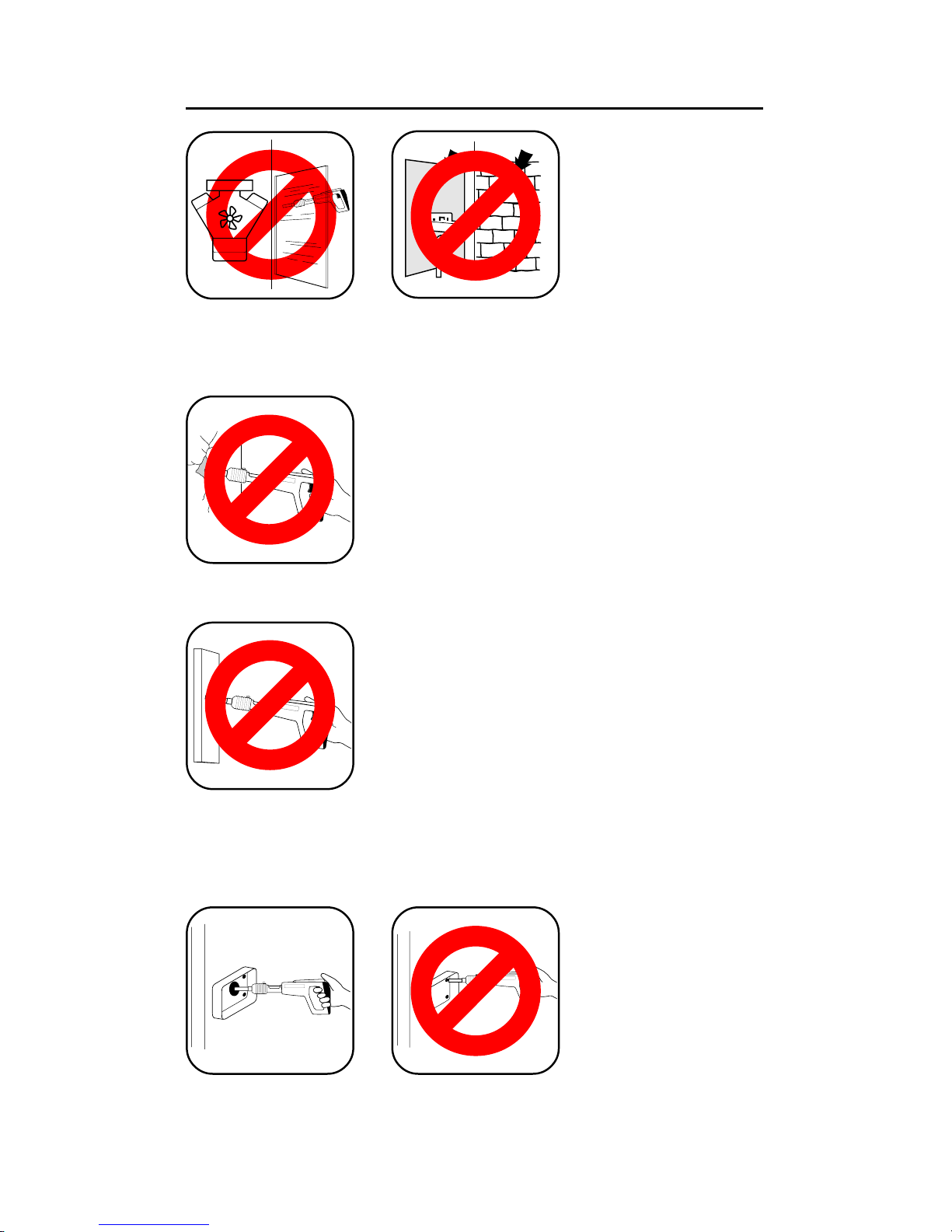

Warning: Safety Precautions ............................................................ 1-9

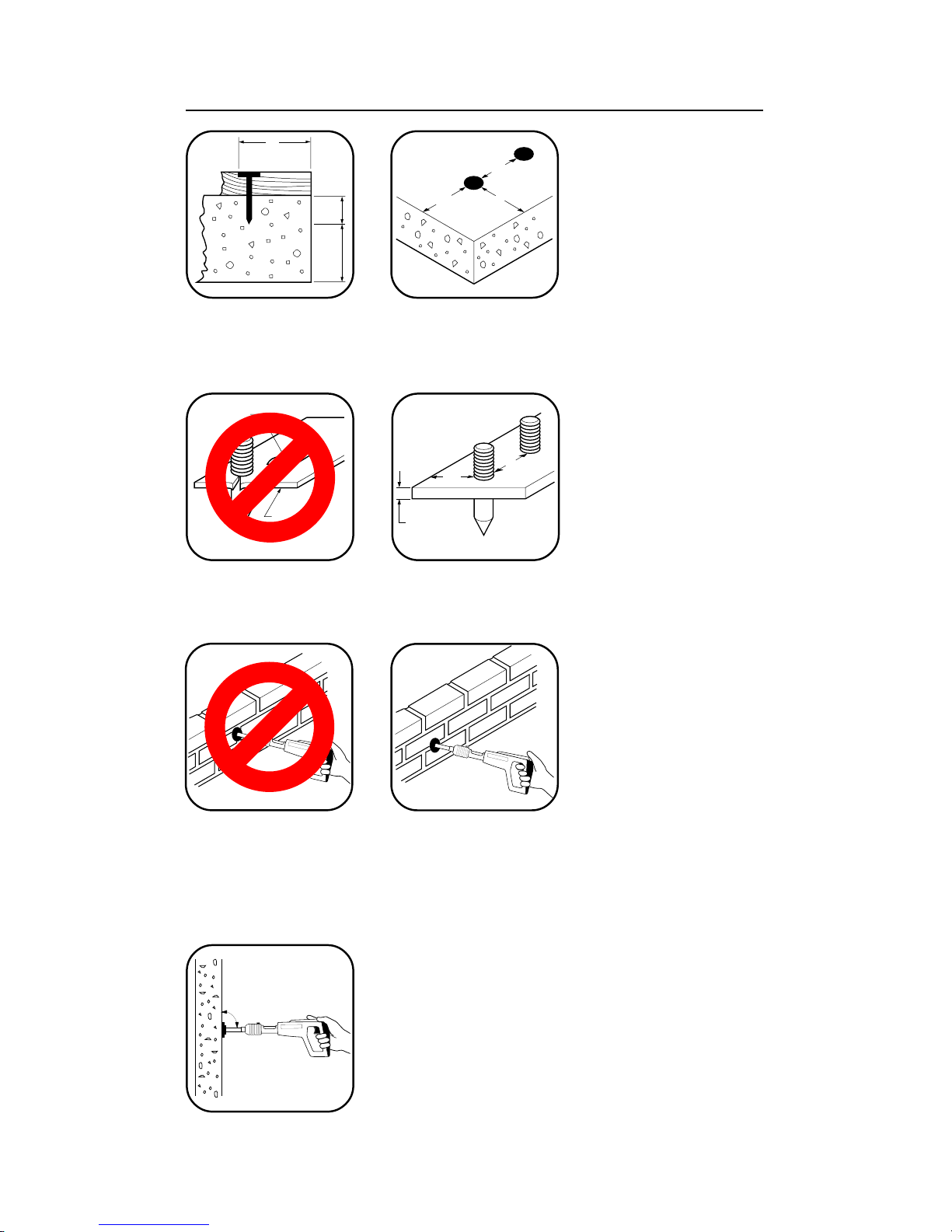

Why A Fastener Holds ....................................................................... 10

Selecting Fasteners and Powder Loads ............................................ 11

Operation ...................................................................................... 12,13

Parts List ............................................................................................ 14

Accessories........................................................................................ 14

Barrel Replacement ........................................................................... 15

Tool Disassembly and Assembly .................................................. 16,17

Troubleshooting ............................................................................ 18,19

Fasteners ........................................................................................... 19

Application Chart........................................................................... 20,21

Parts and Accessories ....................................................................... 21

Warranty...............................................................................Back Cover

REMINGTON

Powerdriver Models 489 and 490

TheRemingtonPowerdriverModels489and490aredesignedforuse

withRemingtonpowder22caliberTypeAcrimpedloadsandReming-

ton Power Fasteners which are no longer than 2 1/2". Remington

Power Fasteners are manufactured from special steel and heat

treated to produce a very hard yet ductile fastener.

REMINGTON

490-02

Powder Load*

Maximum 2 1/2"

Trigger

Barrel Assembly

* Not provided with tool.

Spall Shield*

Power Fastener*

Muzzle

Recommended

Approved Eye

Protection*