2

106088

INDEX

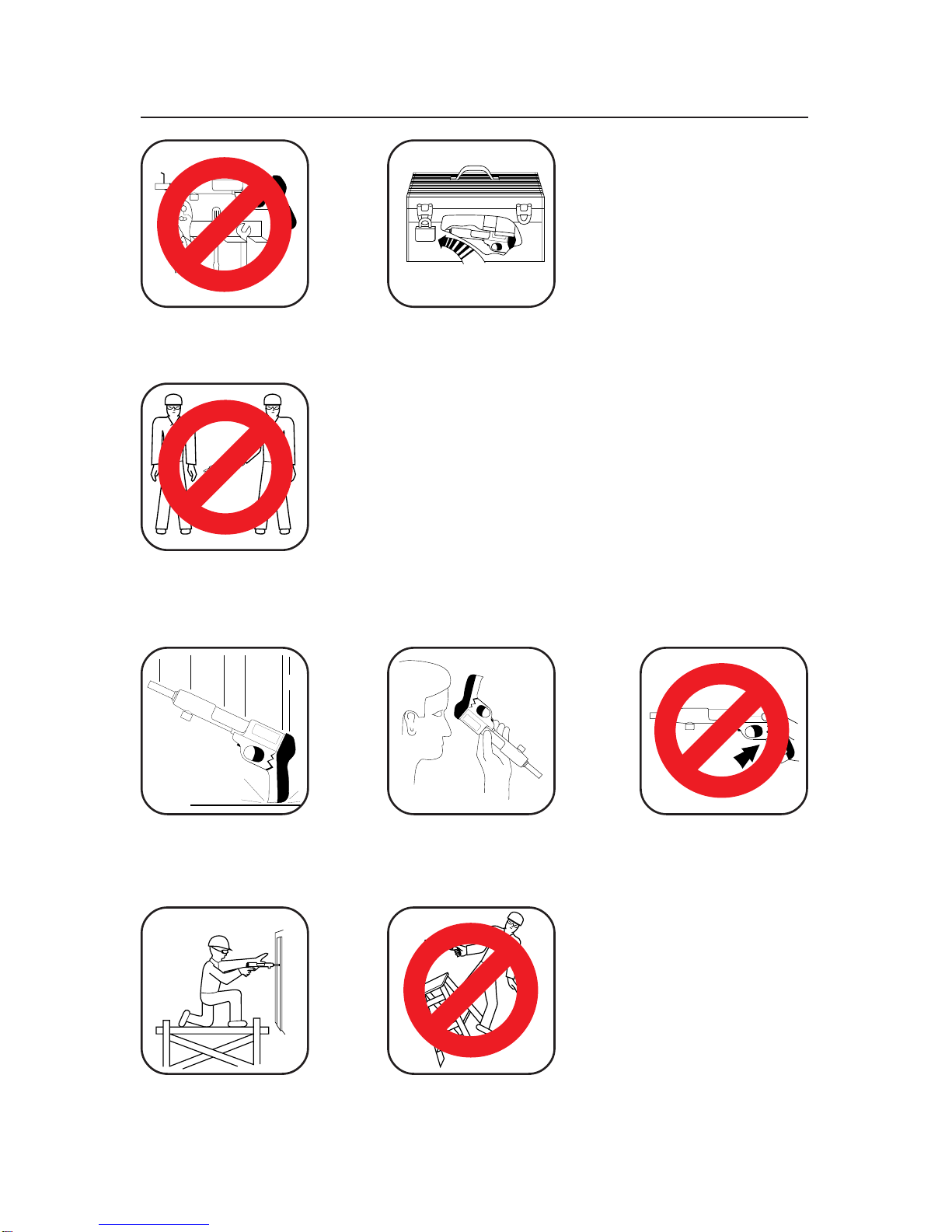

Warning: Safety Precautions............................................................................. 2-11

Why a Fastener Holds.......................................................................................... 12

Selecting Fasteners and Power Loads ................................................................ 13

Operation ....................................................................................................... 14, 15

Maintenance......................................................................................................... 16

Troubleshooting ............................................................................................. 16, 17

Parts Central ........................................................................................................ 17

Parts List .............................................................................................................. 18

Accessories.......................................................................................................... 19

Tool Disassembly and Assembly ................................................................... 19, 20

Buffer and Piston Replacement ........................................................................... 21

Application Chart............................................................................................ 22, 23

Warranty.................................................................................................Back Cover

* Not provided with tool.

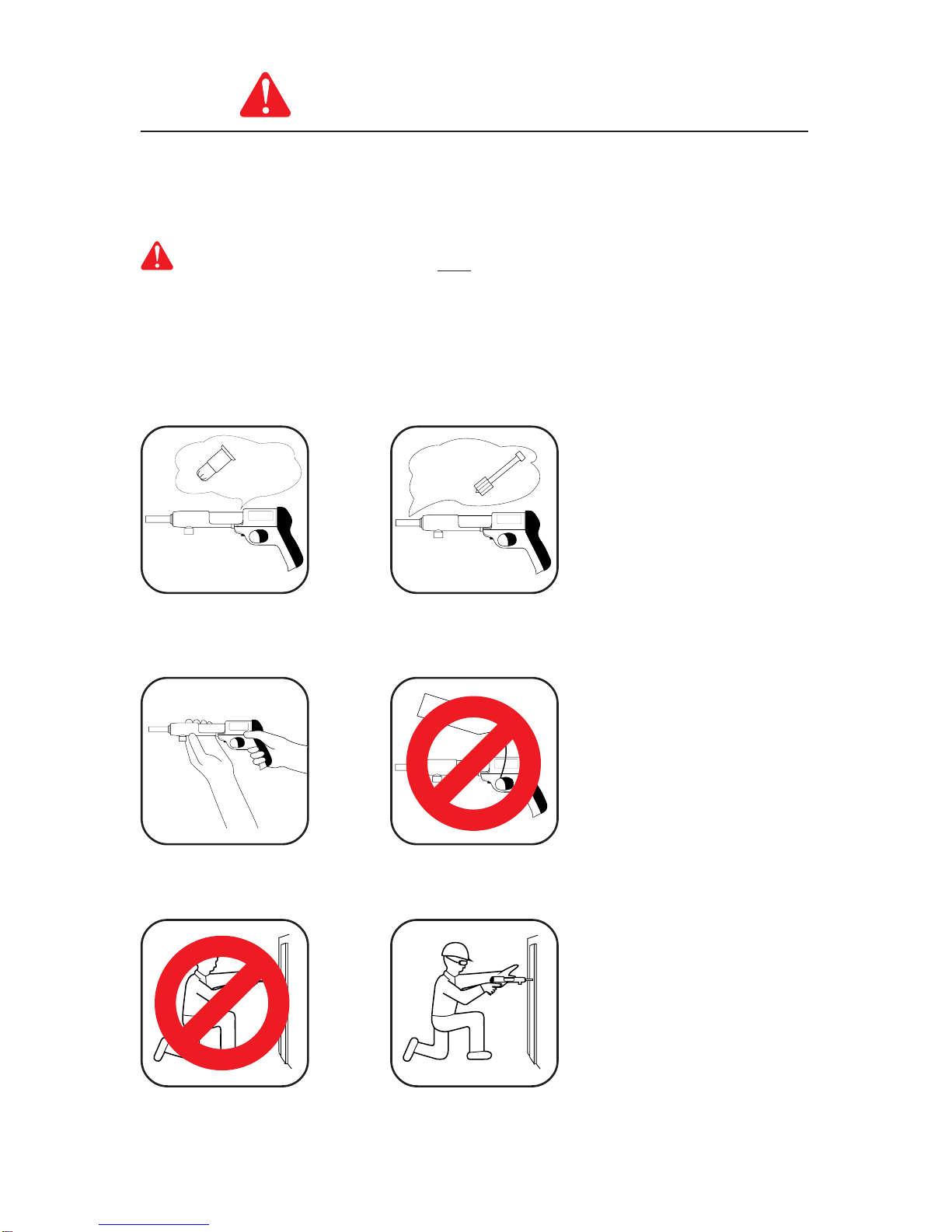

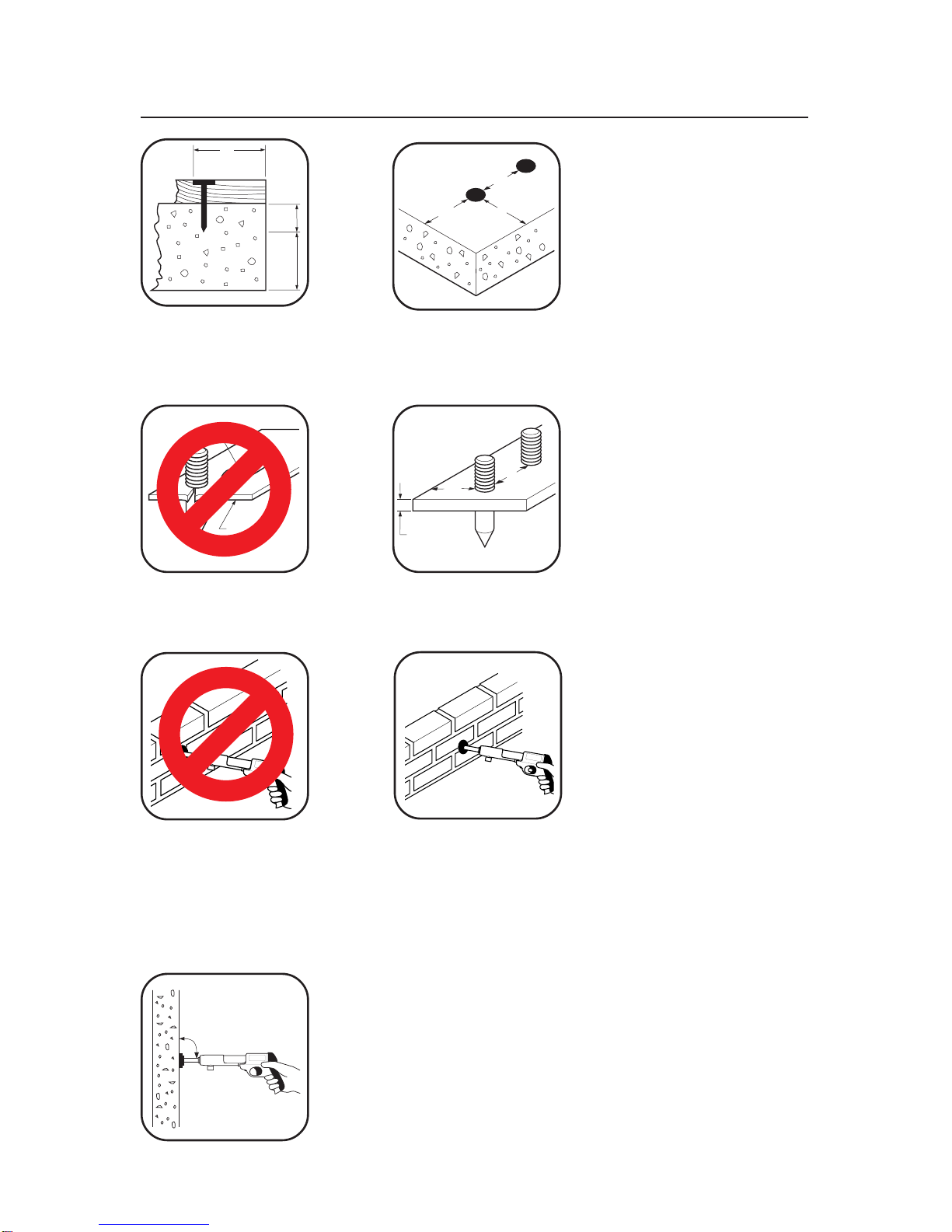

REMINGTON

Power Fastener*

Barrel

Assembly

Trigger

Maximum 2 1/2" - Model 482

Power Load*

Muzzle

Spall Shield

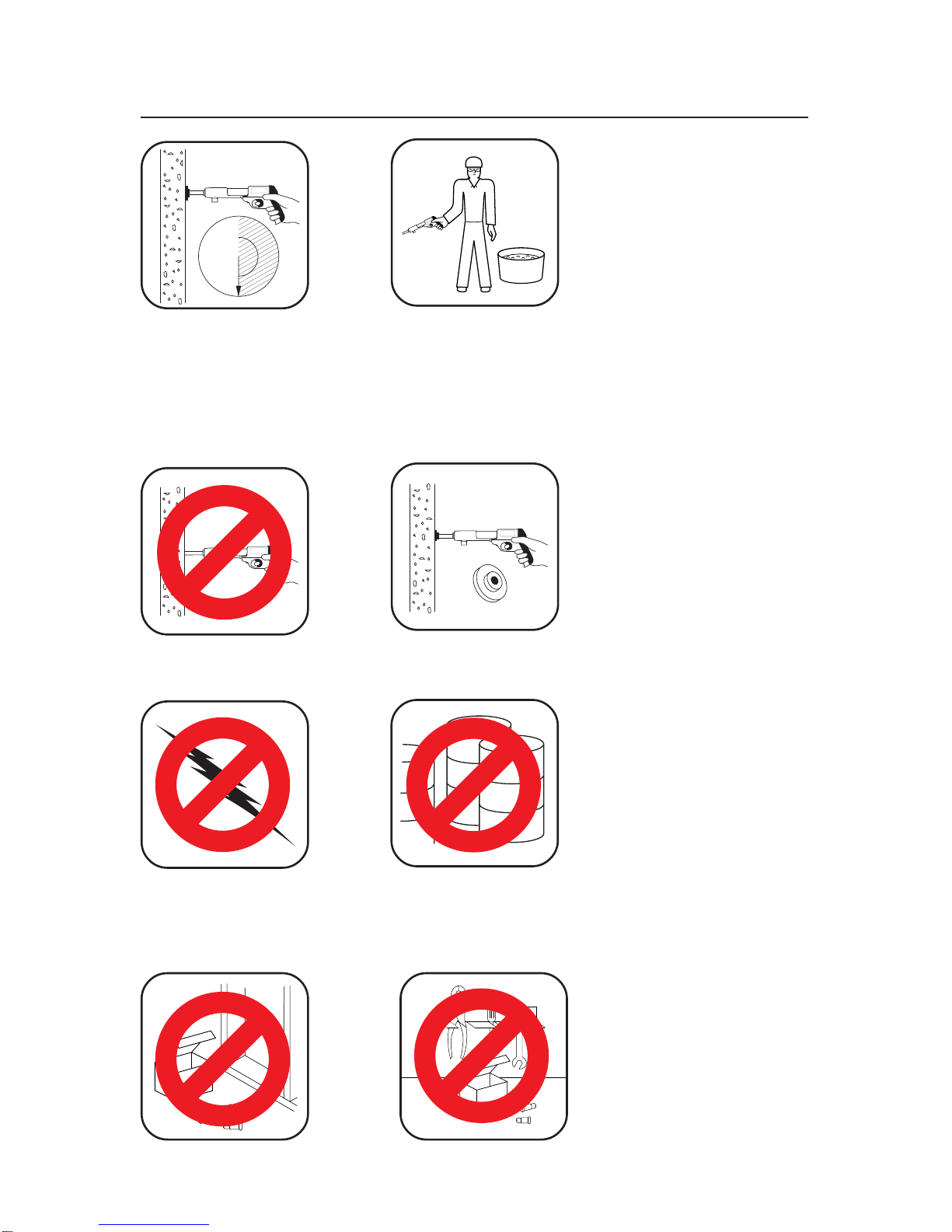

Recommended

Approved Goggles

REMINGTON

Model 482 Powder Actuated Fastening Tools

The Remington Model 482 Powder Actuated Fastening Tool is designed for use

with Remington 22 caliber Type A crimped loads and Remington Power Fasten-

ers. Remington Power Fasteners are manufactured from special steel and heat

treated to produce a very hard yet ductile fastener.