2

114918

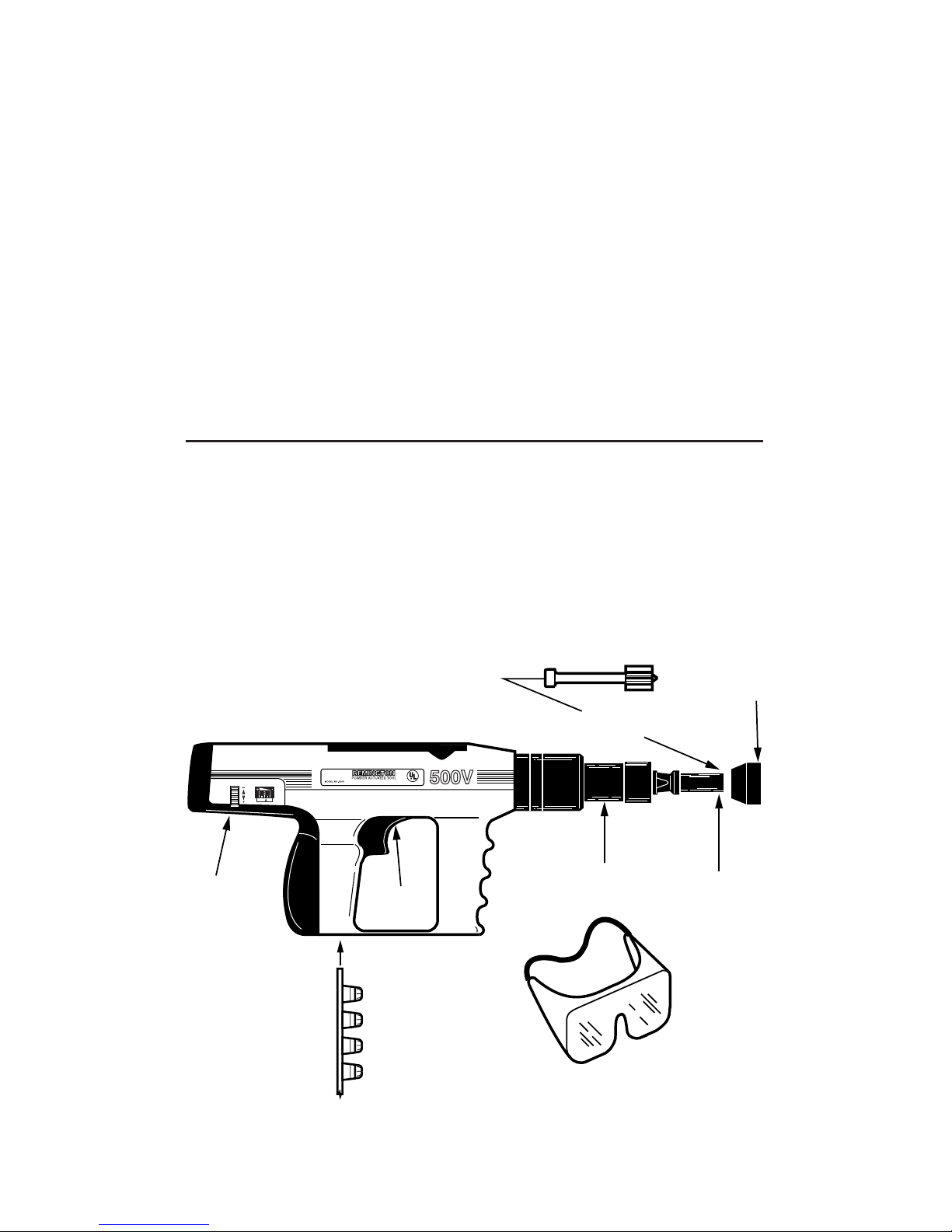

Power Fastener*

Recommended

Approved

Eye Protection

Muzzle/

Guide

Barrel

Assembly

Trigger

Spall

Shield

10-Shot

Power Load

Strip*

*Not provided with tool

Power

Indicator

Adjustment

Wheel

Index

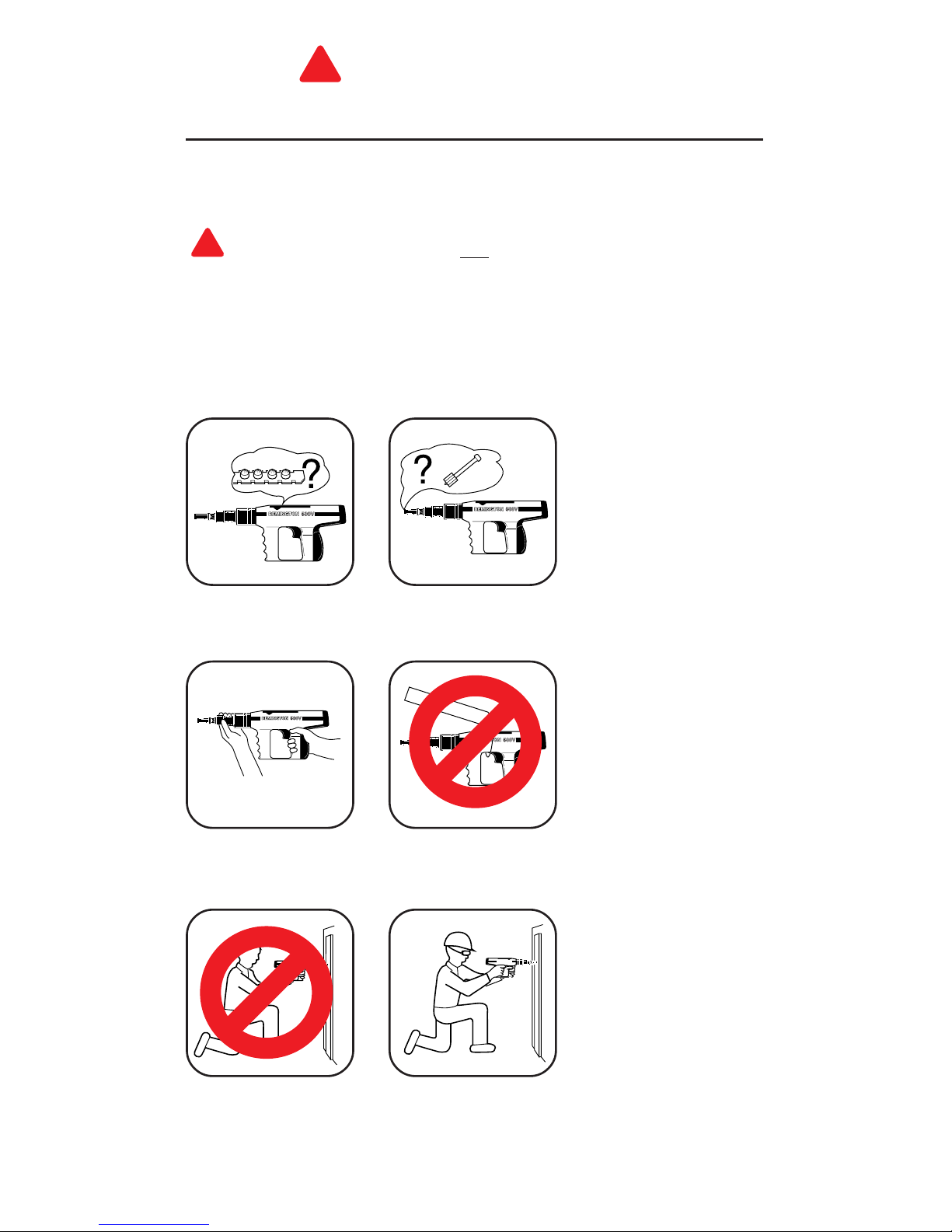

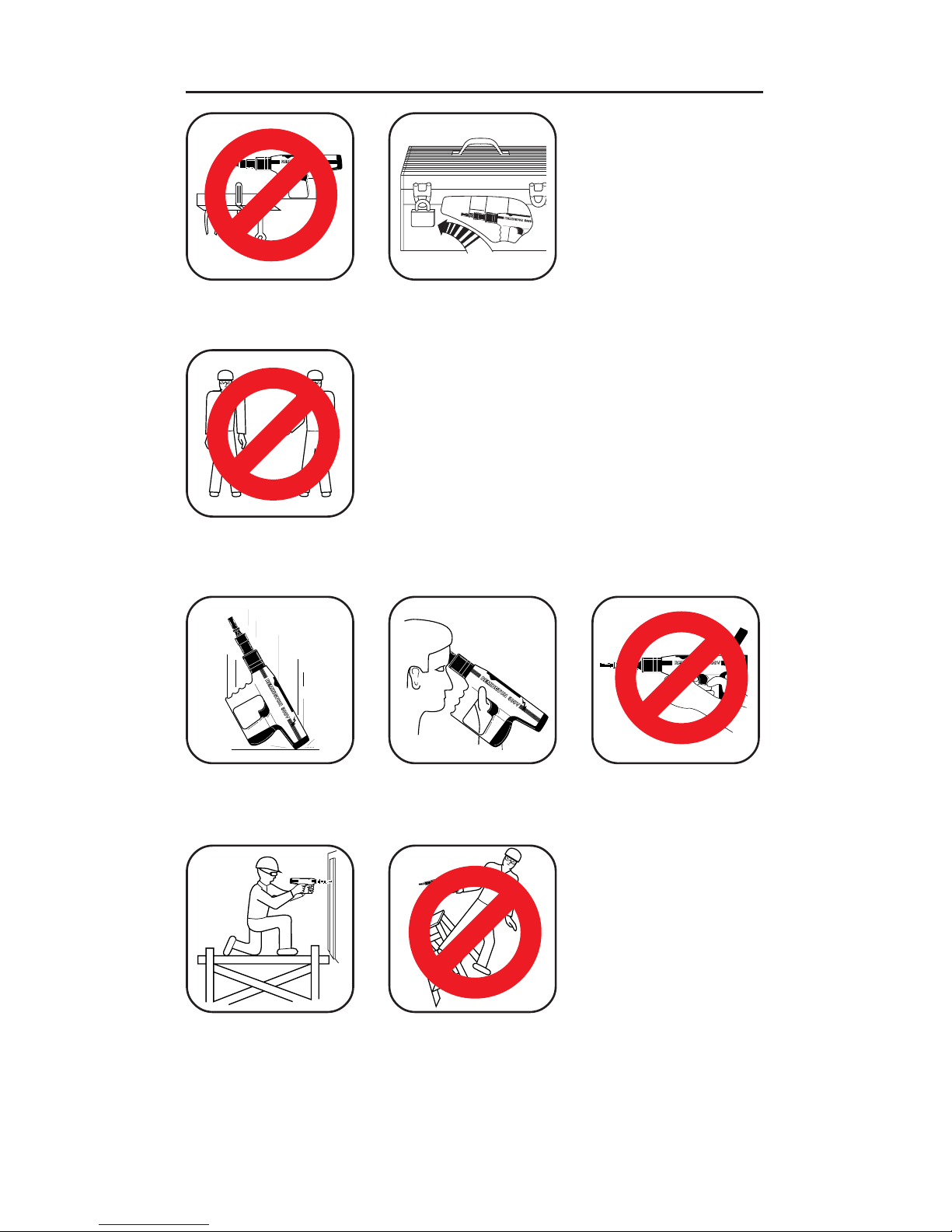

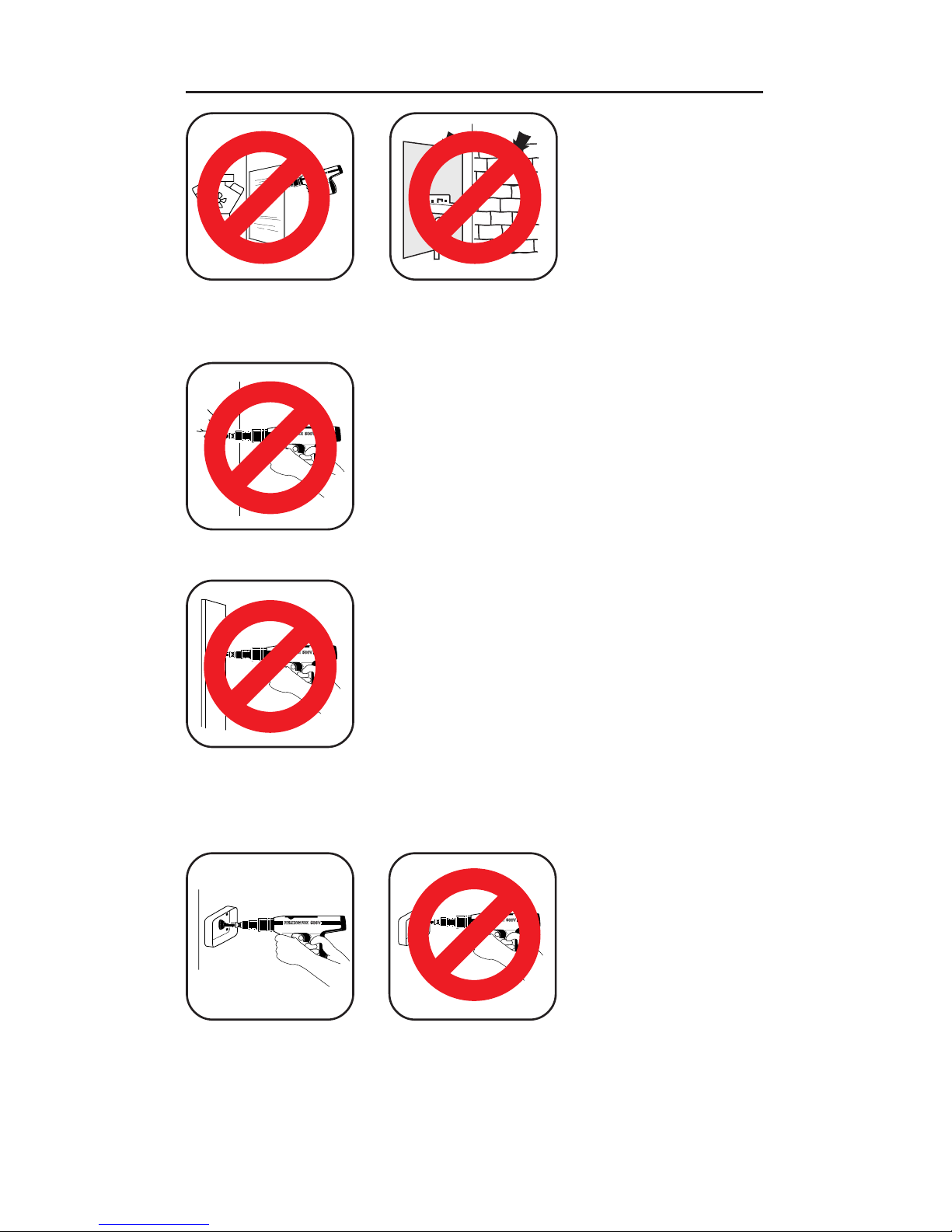

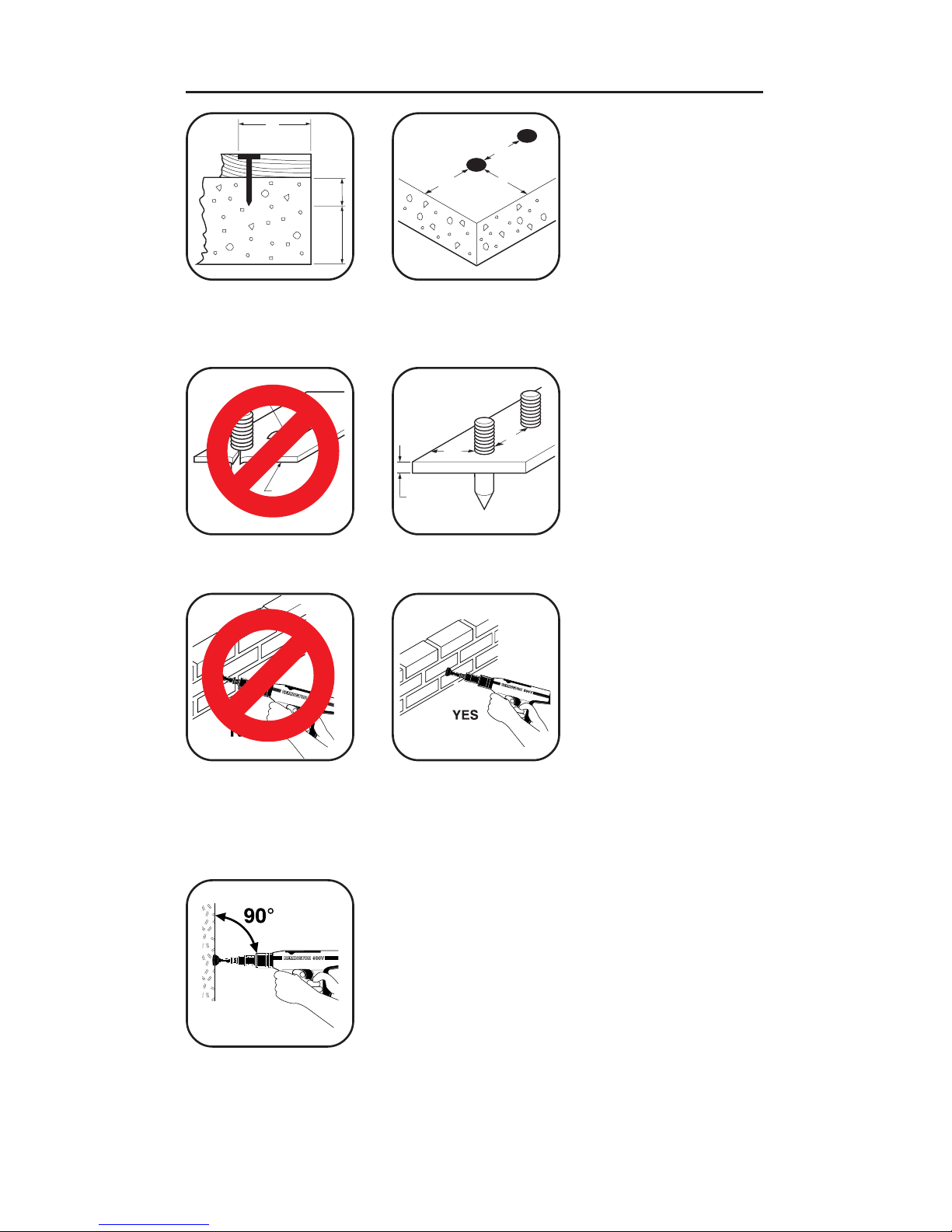

Warning: Safety Precautions .......................................................................... 3-11

Why A Power Fastener Holds ............................................................................ 12

Selecting Power Fasteners and Power Loads ................................................... 13

Operation ...................................................................................................... 14-16

Maintenance ...................................................................................................... 16

Parts List ...................................................................................................... 16, 17

Accessories ........................................................................................................ 17

Tool Disassembly and Assembly .................................................................. 18-25

Troubleshooting Guide ................................................................................. 26, 27

Application Chart .......................................................................................... 27, 28

Replacement Parts and Accessories ................................................................. 29

Technical Service ............................................................................................... 29

Repair Service ................................................................................................... 29

Parts Centrals .................................................................................................... 30

Limited Warranty ................................................................................................ 31

REMINGTON®

Power Pro™ Semi-automatic Model 500V

The Remington®Power Pro™ Model 500V is designed for use with Remington®.27

caliber power load strips and Remington®power fasteners. Remington®power

fasteners are manufactured from special steel and heat treated to produce a very

hard, yet ductile, fastener.