6

REMKO GPC series

the cable passages for the electrical lines as well

astheplug connection for the power supply.

Intheright-hand side section the necessary

components for the control and safety are found

behind the inspection door, including e.g.:

- the electrical circuitry with the cabling

- the control electronics

- the gas valve

- the modulating gas burner

In the interior of the unit, directly in the circulation air

flow, is the combustion chamber with heat exchanger.

The combustion chamber is manufactured entirely

from Inox stainless steel, AISI 441. For increased

resistance to corrosion from damp vapours, Inox

stainless steel, AISI 441 is used for the heat exchanger.

The special form and the large surface area

ofthecombustion chamber and heat exchanger

guarantee ahigh level of efficiency and long service

life.

The gas burner is likewise manufactured entirely from

special, mechanically-processed stainless steel.

Function of the units

The modulating, gas wall-mounted automatic heaters

of the GPC series has been developed for the heating

of industrial and commercial spaces.

The electronic control of the unit regulates the heat

output according to the actual requirement, between

minimum and maximum output.

With the pre-mix and modulation technology,

efficiency of up to 108% can be achieved.

The nominal heating capacity of the REMKO GPC

series lies between 4.7 and 82.0 kW.

The units consist primarily of the combustion chamber

with heat exchanger and the fan(s).

The ambient air is drawn in by the fan(s)

andefficiently channelled through the combustion

chamber with heat exchanger. The combustion

chamber is heated by the gas burner operation

andreleases its heat to the air flowing past.

Theairheated in this manner is blown out of the front

side of the unit through an adjustable outlet grille.

Operation of the unit as intended is only possible

with a connected temperature controller, e.g. ATR-10

(accessory).

Unit description

Definition of the unit

Pursuant to EU Directives, the unit is defined as:

"Gas fan-assisted heater (WLE) without flow-

operated safety device, equipped with a fan in front

of the heat exchanger".

The unit is a fully-automatic, directly-fired fan-assisted

air heater for wall and ceiling installation.

It can be fuelled with natural gas or liquid gas.

The unit is used for continuous and temporary

heating of open and closed spaces, e.g. in:

halls, workshops,

greenhouses,

storage rooms, etc.

Classification of the units

The units have been classified by the European

standardised regulations EN 437, EN1196 and EN

1020 according to:

The gas category:

Determination according to the type of gases

withwhich they may be operated.

For Germany DE II2ELL3B/P

The gas type:

The burner can be operated with gases of the second

family (natural gas - group H and L) and with gases

ofthe third family (butane and propane).

The type of gas fireplace:

Differentiation according to the possibilities

ofthedischarge of the combustion products

orthesupply ofthe combustion air.

(ambient-air-dependent/independent)

Additional notes can be found in the chapter

"Installation of the flue gas evacuation

andthecombustion air supply".

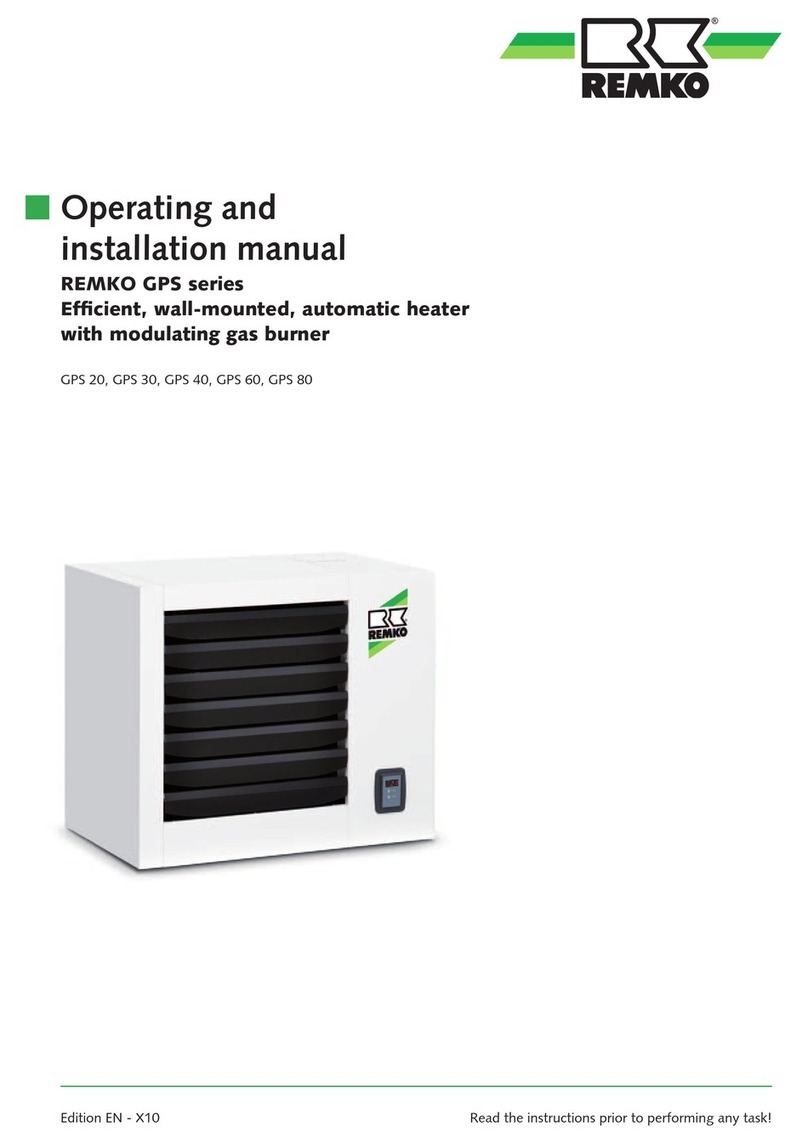

Design of the units

The exterior cladding of the units is made from coated

steel sheet, which guarantees durability.

The outlet grille is found in the front section.

In order to ensure an optimal distribution of warm

airin the installation location, the horizontal fins

ofthe outlet grille can be manually adjusted.

Onthe rear side of the unit you will find thefan(s)

with protection grid, the connection nozzles

for theremoval of the flue gas and supply

ofthecombustion air, the gas connection nozzles,