1

Contents

1.Introduction...........................................................................................................................................................2

1.1 Introduction....................................................................................................................................................2

1.2. Applied designations....................................................................................................................................2

1.3. Important safety information.........................................................................................................................3

1.4. System sizing...............................................................................................................................................3

2. Technical description of inverters.......................................................................................................................4

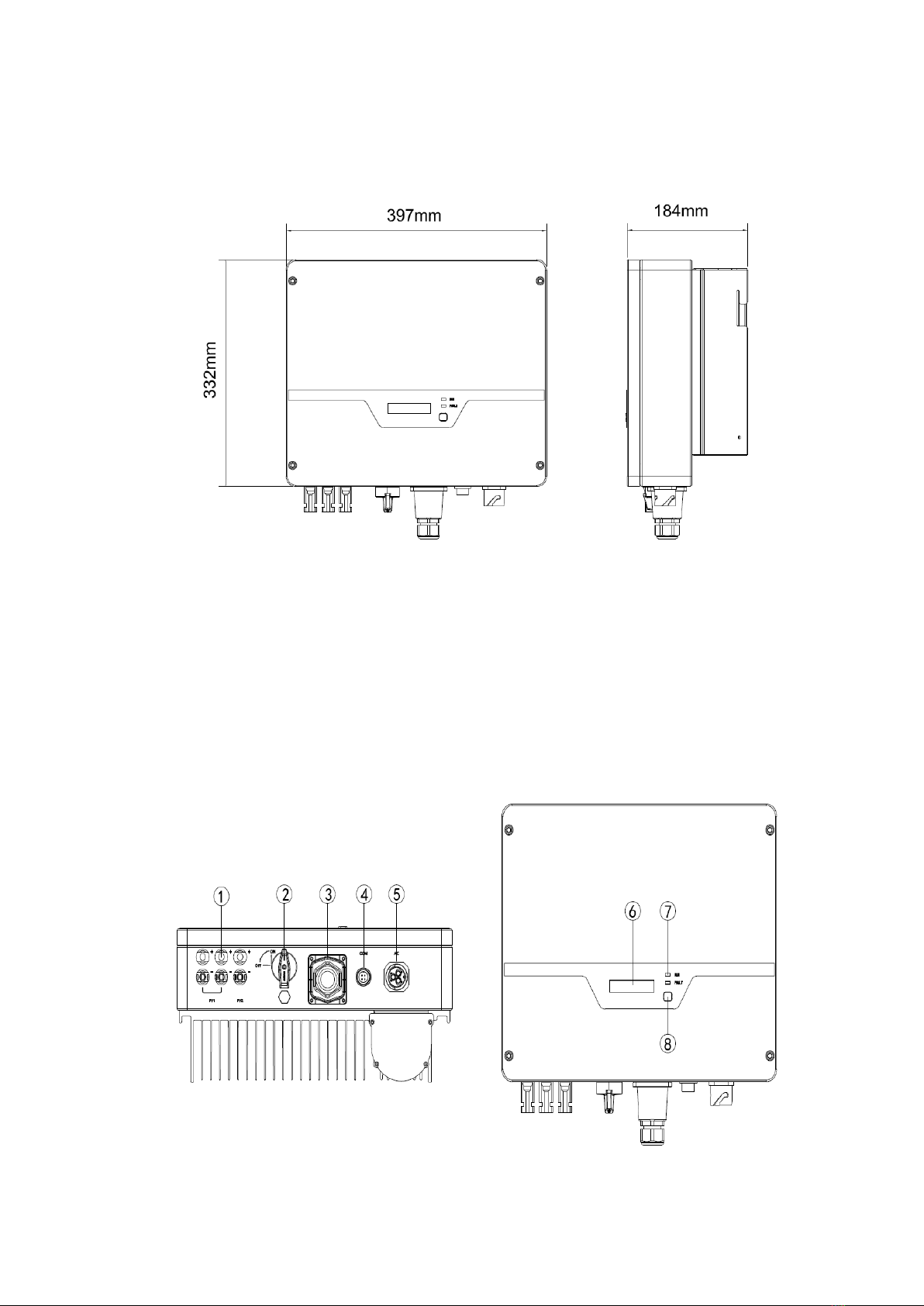

2.1. Mechanical design........................................................................................................................................ 4

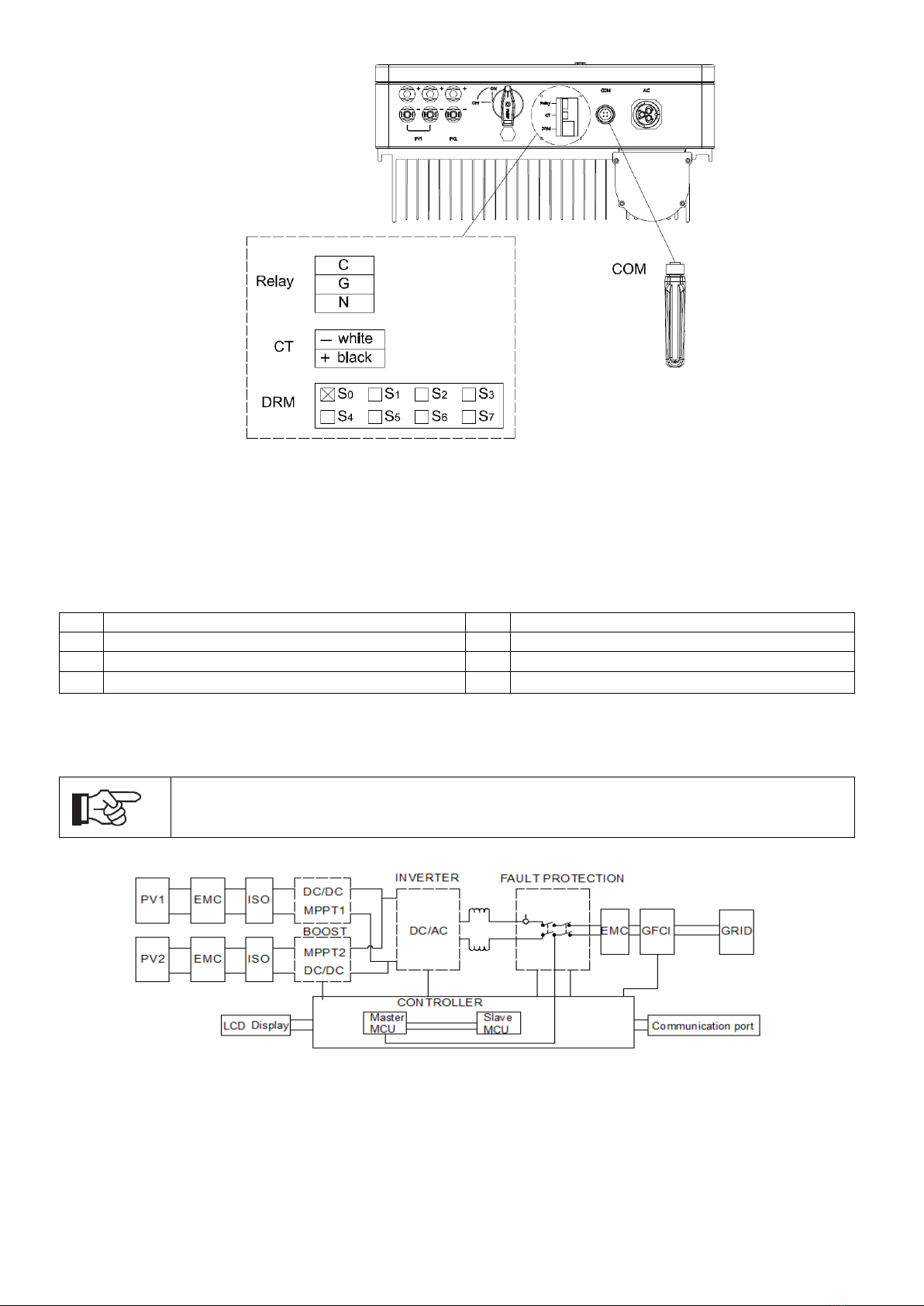

2.2. Electrical system design...............................................................................................................................5

2.3. Technical data..............................................................................................................................................6

2.4. Grid codes....................................................................................................................................................7

3. Installation and startup........................................................................................................................................8

3.1. Package information.....................................................................................................................................8

3.2. Installation environment ...............................................................................................................................8

3.3. Installation position.......................................................................................................................................9

3.4. Mounting procedure ...................................................................................................................................10

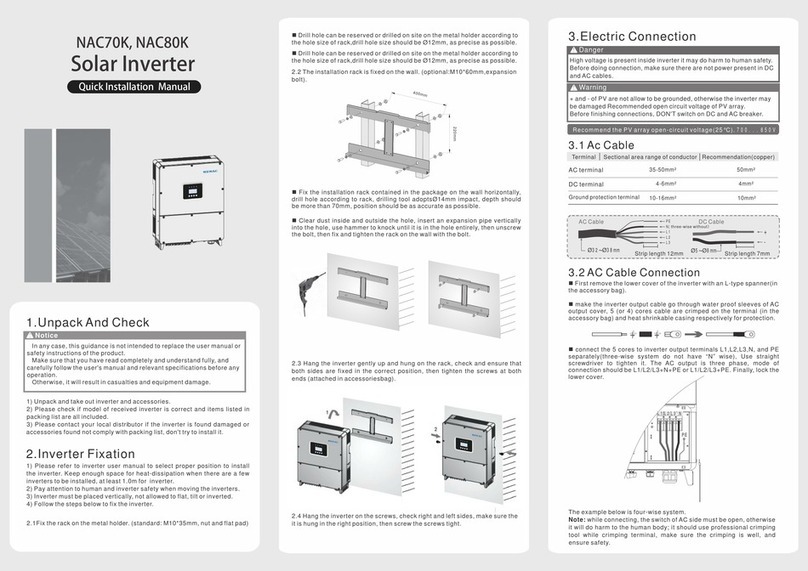

3.5. Electrical connection ..................................................................................................................................11

3.6. Starting the inverter....................................................................................................................................14

4. User interface....................................................................................................................................................14

4.1. Led and key................................................................................................................................................14

4.2. LCD display................................................................................................................................................15

4.3. Factory setting............................................................................................................................................15

4.4. Setting language ........................................................................................................................................16

4.5. Setting modbus address ............................................................................................................................16

4.6. Setting export power (CT)..........................................................................................................................16

4.7. Self-Test in accordance with CEI 0-21 (Applies to Italy only)....................................................................16

5. Warranty............................................................................................................................................................18

5.1. Warranty claim procedure..........................................................................................................................18

5.2. Service after warranty expiration................................................................................................................18

Appendix A: FAQ (Frequently asked questions)...................................................................................................19