RA4W1 Group Guidelines for 2.4 GHz Wireless Board Design

R01AN4886EJ0100 Rev.1.00 Page 5 of 18

May.07.20

2.2 Oscillator circuit for the Wireless-dedicated (Bluetooth-dedicated) clock

Note the followings when designing the Wireless-dedicated (Bluetooth-dedicated) clock oscillator circuit.

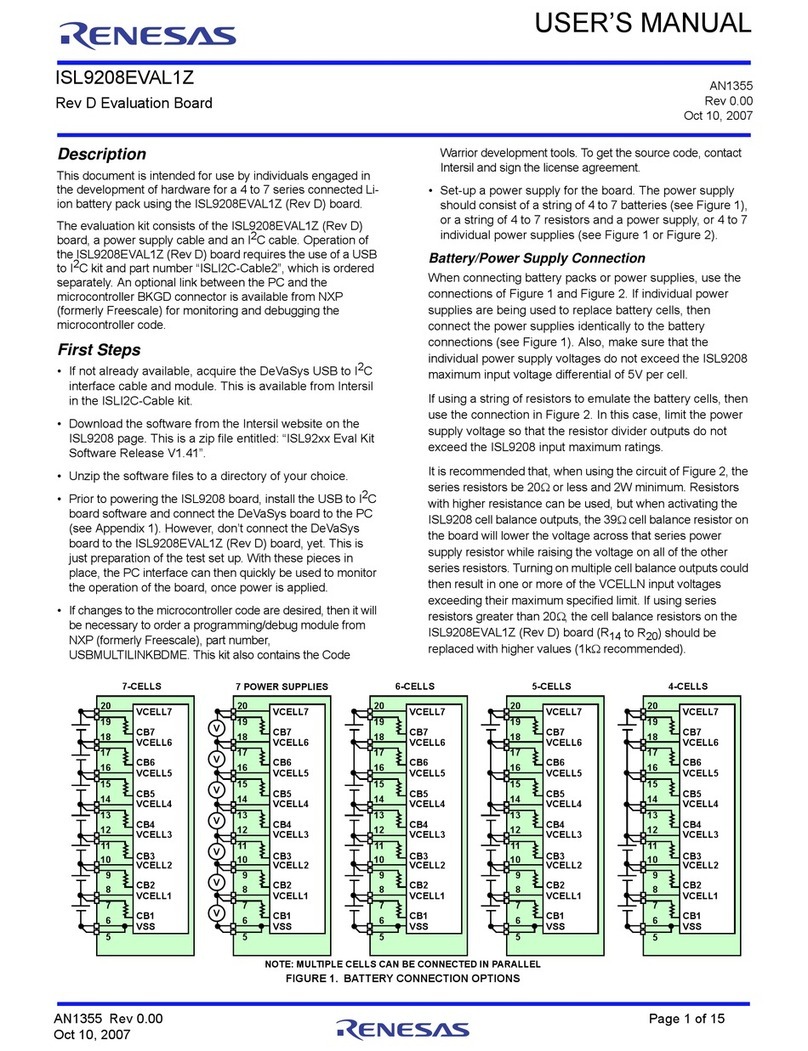

Figure 2-1 shows an example of the crystal resonator connection. Figure 2-2 shows an example of the

pattern around the crystal resonator.

•Place the crystal resonator close to the “XTAL1_RF” and “XTAL2_RF” pins. In case of the Figure 2-2, the

distance between these two pins and the crystal resonator is approximately 6 mm.

•Shield lines from the “XTAL1_RF” and “XTAL2_RF” pins to the crystal resonator with the ground pattern.

Do not place the pattern for these signals in parallel with or across other patterns where a large current

flows or a signal level changes frequently.

•Do not place any signal, power or ground lines other than those for the oscillator circuit on and below the

oscillator circuit lines and area. As shown in Figure 2-2, the ground pattern is placed in the layers under

the oscillator circuit.

•Separate the oscillator circuit and a signal line from an antenna to the “ANT” pin by placing slit patterns

on all layers.

•As shown in Figure 2-2, ensure the return path in layer2, and the layer3 if possible, from ground of the

crystal resonator to "Exposed Die Pad (VSS_RF)”.

•Any external load capacitor of the crystal resonator for a frequency tuning of the oscillator is not required,

because capacitors to tune the frequency of the oscillator are built in the chip. With respect to the tuning

procedure of the Wireless-dedicated (Bluetooth-dedicated) clock frequency, refer to descriptions of the

application note [1].

•As shown in Figure 2-1, insert a damping resistor (Rd) as required. Determine the resistance to the value

recommended by an oscillator manufacturer as the value depends on the oscillator and its driving

capability. A feedback resistor (Rf) between the “XTAL1_RF” pin and the “XTAL2_RF” pin is not required

on the board. The feedback component is built in the RF transceiver instead of the Rf.

•The resistance of the Rd and Rf should be determined by oscillation characteristics evaluation with a

crystal resonator to be mounted. Theses resistors are not always required, depending on the oscillation

characteristics.

•When the Wireless-dedicated (Bluetooth-dedicated) clock from the “CLKOUT_RF” pin is used, the wiring

length from the “CLKOUT_RF” pin should be as short as possible. The wire must not branch. The

maximum number of Vias of the wiring from the “CLKOUT_RF” pin to the external clock input pin of MCU

is tow.

•Shield the transmission line of the “CLKOUT_RF” with the "VSS" pattern to avoid noise coupling to

“VSS_RF”.

Note: Carefully consider and determine your crystal resonator in consultation with a crystal resonator

manufacturer because the oscillation characteristics depend on a board design. For example, in the

case of the Bluetooth 5.0 standard, the transceiver clock frequency tolerance which includes an initial

error, a temperature drift, and an ageing effect should be less than or equal to +/– 50 ppm. Especially,

the initial error should be minimized as possible by [1].