S8910U UNIVERSAL HOT SURFACE IGNITION MODULE

69-0845—03 6

Corrosive Chemicals

Corrosive chemicals can attack the module and gas

control, eventually causing a failure. If chemicals are

used for routine cleaning, avoid contact with the controls.

Where chemicals are suspended in air, for some

industrial or agricultural applications, a NEMA 4

enclosure is recom-mended for the ignition module; see

the Electronic Ignition Service Manual, form 70-6604.

Dust or Grease Accumulation

Heavy accumulations of dust or grease can cause

controls to malfunction. Where dust or grease can be a

problem, provide covers for the module and the gas

control to limit contamination. A NEMA 4 enclosure is

recommended for the ignition module; see the Electronic

Ignition Service Man-ual, form 70-6604.

Heat

Excessively high temperatures can damage controls.

Make sure the maximum ambient temperature at the

control does not exceed the rating of the control. If the

appliance operates at very high temperatures, use

insulation, shielding, and air circulation as necessary to

protect the controls. Proper insulation or shielding

should be provided by the appliance manufacturer; verify

proper air circulation is maintained when the appliance is

in-stalled.

INSTALLATION

When Installing this Ignition

System...

1. Read these instructions carefully. Failure to follow

them could damage the components or cause a

hazardous condition.

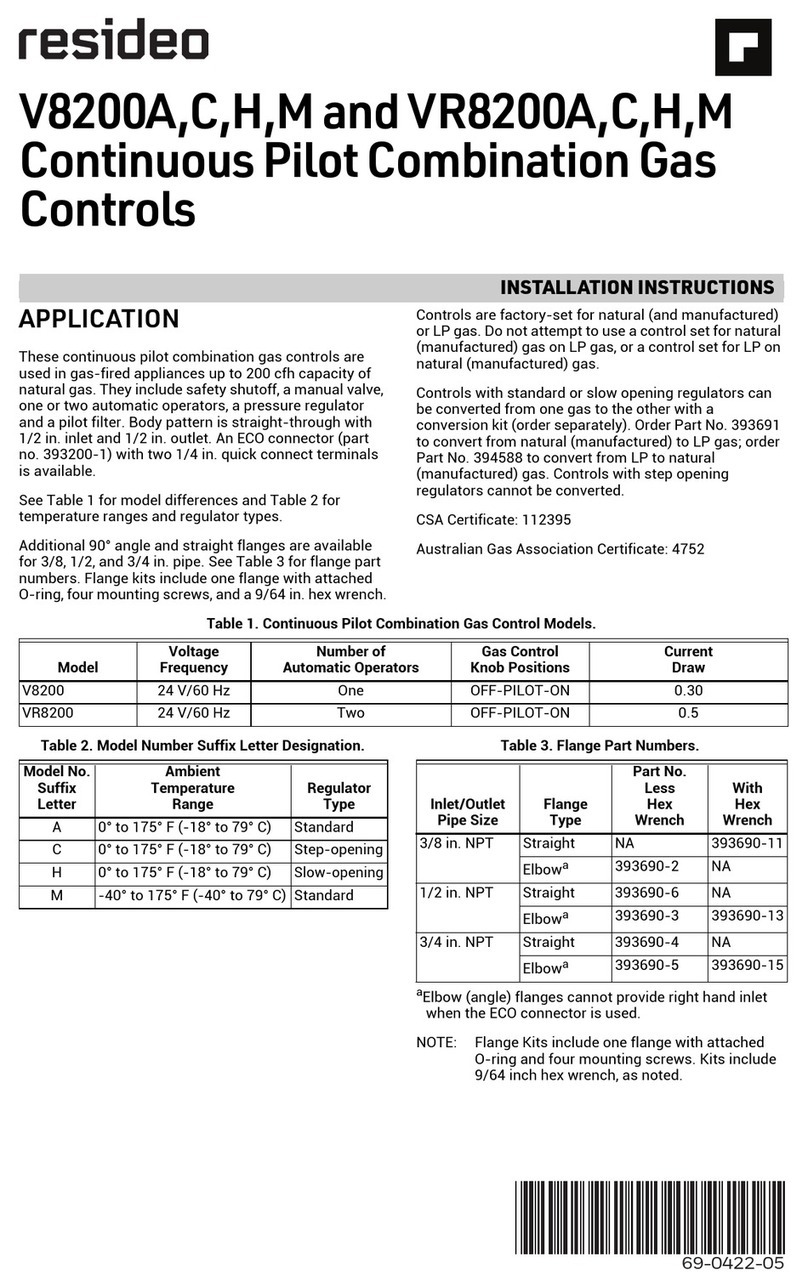

2. Check Table 1 through 3 to confirm that the

S8910U is a direct replacement for the existing

module.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out compo-

nent and appliance operation as provided in these

instructions.

FIRE OR EXPLOSION HAZARD CAN CAUSE

PROPERTY DAMAGE, SEVERE INJURY, OR

DEATH.

1. If the ignition module gets wet, it can

malfunction, leading to accumulation of

explosive gas.

• Never install where water can flood, drip or

condense on the module.

• Never use a module that has been wet.

Replace it.

2. Liquefied petroleum (LP) gas is heavier than air

and will not vent upward naturally.

• Do not light the pilot or operate electric

switches, lights or appliances until you are

sure the appliance area is free of gas.

3. Do not attempt to disassemble or clean the

module. Improper reassembly and cleaning

can cause unreliable operation.

1. Disconnect the power supply before beginning

wiring to prevent electrical shock or equipment

damage.

2. If a new gas control is to be installed, turn off

the gas supply before starting the installation.

After the gas control is installed, conduct a Gas

Leak Test according to the gas control

manufacturer instructions.

3. If a module must be mounted where it can be

exposed to moisture or water, provide a

suitable waterproof enclosure.

4. Using the wire labels provided, label all the

wires before disconnecting. Wiring errors can

cause improper appliance operation and

dangerous conditions such as bypassing

safety features.

Perform Preinstallation Safety

Inspection

A preinstallation safety check of the appliance and

venting system must be done before the replacement

module is installed. If a condition is detected that could

result in unsafe operation, shut off the appliance and

advise the owner of the unsafe condition. Correct any

potentially unsafe condition before proceeding with the

installation.

Remove Old Module

Disconnect the power supply before doing any work on

the unit. Disconnect and tag the wires from the old

module using the wire labels provided. Remove the old

module from its mounting location.

Mount New Ignition Module

Mount the S8910U Module in the same location as the

old module. Protect the module from exposure to water,

moisture, corrosive chemicals and excessive dust and

grease. Assure that ambient temperature at the module

is within the range listed in the Application section.

Mount the module with the terminals down to protect

from dripping water and dust. The module can also be

mounted with terminals on either side. Do not mount

with the terminals pointing up. Refer to Fig. 1 for

mounting recom-mendations. When it is necessary to

drill new mounting holes, use the S8910U as a template

to mark the mounting hole pattern. Drill new holes as

required. Fasten securely with four No. 6-32 machine or

No. 8 sheet metal screws.

Install Selection Tab

Four selection tabs are included with the S8910U. See

Table 1 through 3. Select the correct tab for the system

and separate the tab from the other three tabs. Install the

tab on the module. Be sure the selection tab is properly

positioned and firmly inserted. See Fig. 2. Discard all

unused selection tabs at a remote location so an

incorrect tab cannot be used in the future. Without a

selection tab, the module operates at four-second trial

time and one ignition trial.