3

EN1R- 9099 2004R8- NE

Mounting position

The gas control can be mounted 0 to 90

_

in any direction from

the upright position i.e. from the position when the knob is on

top.

Main gas connection

•

Take care that dirt cannot enter the gas control during

handling.

•

Use a clean taper fitting with thread according to BS 21 or

a piece of new, properly reamed pipe, free from swarf.

•

Do not tighten the pipe or pipe fitting too far (see table

below). Otherwise valve distortion and malfunction could

result.

Max. length of pipe thread

1

/

2

”

18.6 mm

•

Apply a moderate amount of good quality thread

compound to the pipe or fitting only, leaving the two end

threads bare. PTFE tape may be used as an alternative.

•

Ensure the gas flows in the same direction as the arrow on

the bottom of the gas control.

Pilot gas connection

•

Square off the end of tubing and remove burrs.

•

Slip compression fitting over tubing.

•

Insert tubing into gas control housing until it bottoms, slide

fitting into place and turn finger tight.

•

Use a wrench to tighten fitting about

3

/

4

turn beyond finger

tight to make a pressure tight joint.

Do not use jounting

compound.

•

Connect other end of tubing to pilot burner according to the

pilot burner manufacturer’s instructions.

CAUTION

Do not bend tubing at gas control after compression

fitting has been tightened, as this may result in gas

leakage at the connection.

Thermocouple connection

The gas control has an electrical thermocouple connection

and must therefore be kept clean and dry; thread compound

should never be applied to it. Tighten only

1

/

4

turn beyond

finger tight in order to give good electrical connection. When

routing the thermocouple tubing, do not bend it too sharply

(min. radius 2.5 mm).

Perform gas leak test

WARNING

FIRE OR EXPLOSION HAZARD CAN CAUSE

PROPERTY DAMAGE, SEVERE INJURY OR DEATH

•

With the main burner in operation, paint all pipe joints

(including adapters) and gas control inlet and outlet with

with a rich soap and water solutionan approved leak

detection fluid.

•

If another gas leak is detected, tighten adapter screws,

joints and pipe connections.

•

Replace the part if gas leak can not be stopped.

CAUTION

Keep soap and water solution away from electrical

connections.

Electrical connection

CAUTION

Switch off power supply before making electrical

connections.

Take care that wiring is in accordance with local

regulations.

Follow the instructions supplied by the appliance

manufacturer. If there are no such instructions,

see fig. 2. and 3. for typical wiring diagrams.

Use lead wire which can withstand 105

_

C ambient.

The electric on/off servo operator is provided with:

both 6.3 mm terminals suitable for 6.3 mm receptacles (e.g.

”Series 250” AMP fasteners) and screw terminals,

or provided with:

quick connect terminals suitable for 6.3 mm receptacles

(e.g. ”Series 250” AMP fasteners) or for a female connector

according DIN 43650.

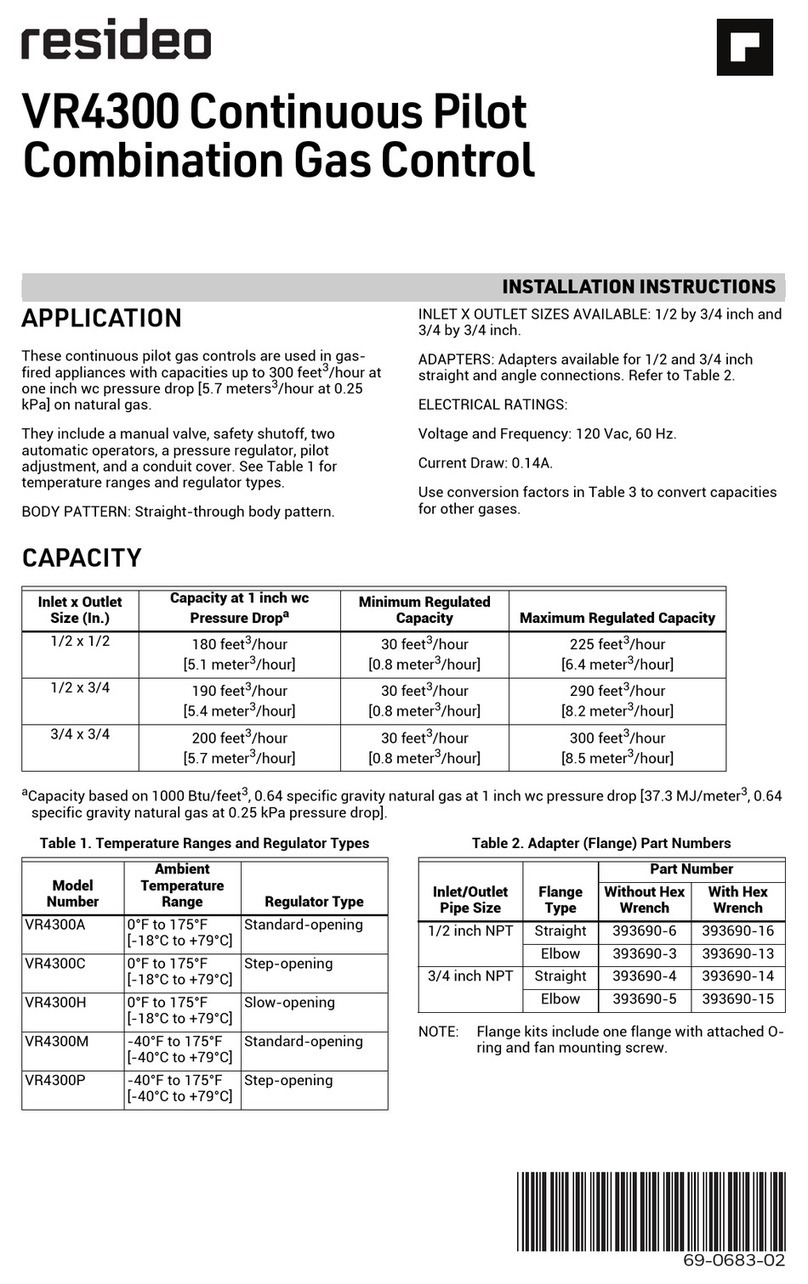

Wiring 220/240 V, 50 Hz (see fig. 2.)

Install the line voltage thermostat (or controller) and other

controls as required.

Provide hard PVC boots on the AMP terminals to prevent

touching of life terminals. When fitting a cover a Heyco

-

type

strain relief should be used.

Wiring 24 V, 50 Hz (see fig. 3.)

Install the transformer, low voltage thermostat and other

controls as required.

Adjust heat anticipater to the A rating as stamped on the gas

control.

Check for gas leaks with a rich soap and water

solution any time work is done on a gas control.

Gas leak test

•

Paint all pipe connections upstream of the gas control with

with a rich soap and water solution.Bubbles indicate a gas

leak.

•

If a gas leak is detected, tighten the pipe connection.

•

Stand clear while lighting the main burner to prevent injury

caused from hidden gas leaks, which could cause flasback

Line voltage

Limit control

Thermostat

Valve operator

in the appliance vestibule. Light the main burner.

Fig. 2. Wiring 220/240 V, 50 Hz