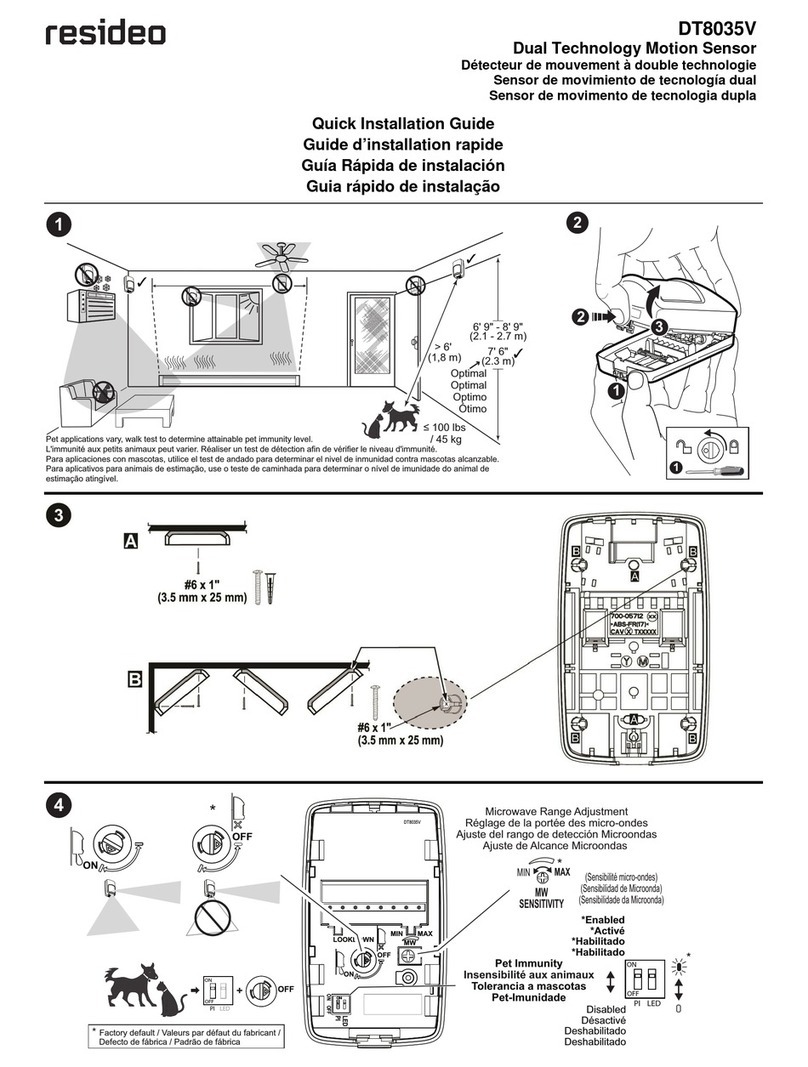

LOCATION GUIDELINES

The FG-1625R/RT detects framed glass broken by an impact sufficient to make a hole.

Refer to the following guidelines when selecting a mounting location:

•The FG-1625R/RT can be mounted in corners, on walls, and on ceilings.

•Mount within 25’ (7.6 m) of the glass.

•There is no minimum range, but the detector must have a clear line-of-sight and a

clear view of the glass.

•The ideal location is on the wall or ceiling directly opposite the glass. The least

desirable location is on the same wall as the glass.

•When wall mounting, mount the detector a minimum of 6’ (1.8 m) high.

•Curtains, blinds and other window coverings absorb energy from breaking glass.

Heavy curtains, for example, effectively block the sound signal. In these cases,

mount the detector on the window frame behind the window covering or above the

window.

•Do not mount within 3’ (0.9 m) of forced air ducts, sirens, or bells measuring 2” (5

cm) or more in diameter.

•Minimize range to the glass. Do not install beyond the maximum specified range

even if testing indicates greater range.

•Adjust sensitivity for desired range; verify by testing with the FG-701.

•Mounting on freestanding posts and pillars is not recommended.

•Verify all installations back to the panel to be sure the protection loop is intact.

•Do not use outside.

•Avoid installing in rooms with high-level noise sources, such as air compressors,

bells, and power tools if those sources can be active when the detector can

signal analarm.

•Test false alarm immunity by activating any noise sources in the room.

Note: The FG-1625R/RT detects shattering of framed glass by a direct impact. It may

not consistently detect breakage by blows that only crack the glass, by high velocity

projectiles (such as bullets) or if the glass is broken without an impact.

USING THE CEILING/WALL TAMPER SWITCH (FG-1625RT ONLY)

The FG-1625RT has a combination normally-closed (NC) cover and wall tamper.

Each detector is shipped with the cover tamper operational and the ceiling/wall

tamper disabled.

•Use needle-nose pliers to break out the plastic tab on the back of the detector. The

tamper arm then extends through the hole.

•The tamper screw (not provided) should be a flat-head #8 (4.2 mm) or Tamper

#10 (4.8 mm) screw.

•Install the tamper screw so it will just make

contact with the bottom of the mounted

detector’s tamper cavity.

•After installing the tamper screw, position the

detector over it and mark

the locations for the mounting screws.

LED INDICATORS

The two LEDs on the front cover indicate the detector's operational status. The

following table summarizes the LED operation when the LEDs are enabled.

Protected glass:

Minimum size for all types is 11 inches (28 cm) square. Glass must be framed in the wall of the

room or mounted in a barrier of 36 inches (0.9 m) minimum width.

1 Protected only if both glass plates are broken.

2 Coated glass with security films up to 0.35mm (14 mils) thick (including films for solar

protection) may be used. Evaluated with these products: 3M® SCOTCHSHIELD®

SH14CLARL – 0.35mm

(14 mils), 4 ply film; Film Technologies International, Inc.’s GLASS-GARD® GGLL 1200 –

0.3mm

(12 mils), 3 ply film by Underwriters Laboratories, Inc., at Resideo’s request.

3 In compliance with Underwriters Laboratories of Canada’s Standard for Intrusion

Detection Units (CAN/ULC-S306-M89)

a ULC recognizes a maximum range of 6m (20 ft.) for protecting 2mm (3/32”) plate and and

3mm (1/8”)laminated.

b ULC recognizes a maximum range for protecting 3mm (1/8”) sealed insulating glass and

all coated glass of 4m (12.5 ft.).

4 UL recognizes a maximum range for protecting 3mm (1/8”) sealed insulating glass of 6m (20

ft.) with sensitivity set at maximum.

IMPORTANT: The FG-1625R/RT must be connected to a UL listed power

supply or UL listed control unit capable of providing a minimum of four hours

of standby power.

2 Corporate Center Drive, Suite 100

P.O. Box 9040, Melville, NY 11747

2020 Resideo Technologies, Inc.

www.resideo.com

SPECIFICATIONS

Range: Operating temperature:

25 feet (7.6m) maximum 14° F to 131°F (-10° C to 55°C)

No minimum range UL: 14° F to 122°F (-10° C to 50°C)

Alarm relay: (Indoor useenvironment)

FG-1625R Form A Storage: -4° F to 131° F (-20° C to 55° C)

FG-1625RT Form C -4° F to 122° F (-20° C to 50° C)

100 mA maximum ESD immunity:

25 VDC maximum 10 kV, Discharges of either polarity to exposed

ON/closed 22ʌ±6ʌsurfaces

OFF/open >1MʌDimensions:

Alarm duration: 4.25” OD x 0.88” THK 5

seconds (unaffected by alarm LED (108 mm x 22.4 mm)

latching) Weight:

Tamper switch: (FG-1625RT only) 4.5 oz., (128 g)

Combination cover and wall tamper Packaged product: 7.5 oz., (213 g) 25

mA maximum Accessories:

24 VDC maximum FG-701 Glassbreak Simulator

Power requirements: FG-SP2 Spacer Plate

8 - 16 VDC; 12 mA typical at Approvals/Listings:

12 VDC, 22 mA max.; FCC and IC Verified

AC Ripple: 4 Volts peak-to-peak UL Listed

at nominal12 VDC ULC Listed

RFI immunity: CE

30 V/m, 10 MHz - 1000 MHz FG-1625RT only:

ESD immunity: EN 50131-1, Grade 2, Class II

10 kV, Discharges of either polarity to Suitable for connection to an EN 60950 Class II

exposed surfaces Limited Power Source

Responsible Party / Issuer of Supplier’s Declaration of Conformity: Ademco Inc., a subsidiary

of Resideo Technologies, Inc., 2 Corporate Center Drive., Melville, NY 11747, Ph: 516-577-

2000

For any additional information regarding the compliance of this product to any EU specific requirements,

please contact:

Sécurité Communication

1198, Avenue du Docteur Maurice Donat

BP 1219 - 06254 MOUGINS CEDEX, FRANCE

Tel.: +33 (0)4 92 94 29 50

fax: +33 (0)4 92 94 29 60.

NOTICES

FCC NOTICE: This equipment has been tested and found to comply with the limits for a Class

B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures: 1) Reorient or relocate the receiving

antenna, 2) Increase the separation between the equipment and receiver, 3) Connect the

equipment into an outlet on a circuit different from that to which the receiver is connected,

4) Consult the dealer or an experienced radio/television technician for help.

The user is cautioned that changes or modifications not expressly approved by Resideo

could void the user’s authority to operate this equipment.

IC Notice: This Class B digital device apparatus complies with the Canadian standard

ICES-003. Cet appareil numérique de la Classe B est conforme à la norme NMB-003

du Canada.

Ê5-051-738-00F*Š

This product is manufactured by Resideo and its affiliates.

For the latest U.S. warranty information, please go to: www.resideo.com or Please contact your local

authorized Resideo representative for product warranty information. 5-051-738-00F 7/14 Rev. F

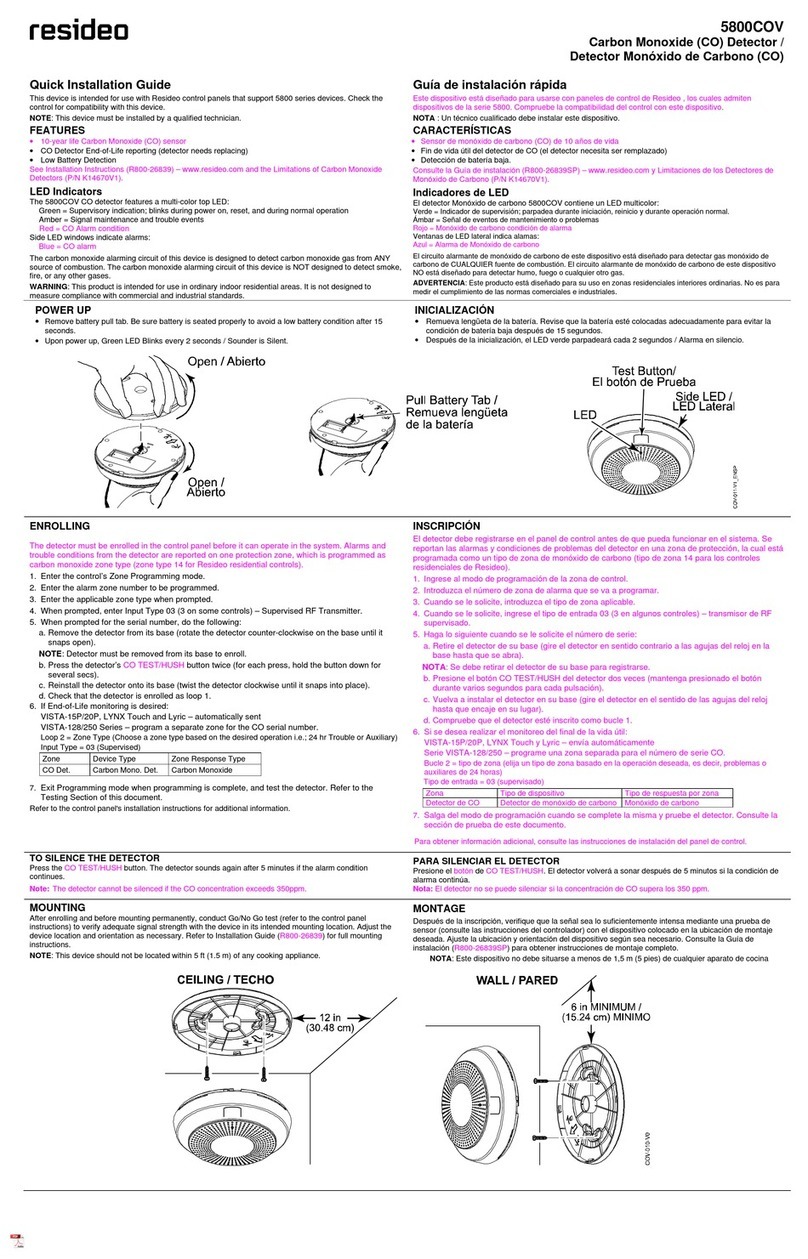

Condition Green LED Red LED

Normal, event detected Flicker OFF

Normal, break detected OFF ON 5 seconds

Normal, alarm latched OFF ON continuously

Power up ON 1 second ON 1 second

Low voltage Flash ON/OFF Flash ON/OFF

Test Mode Flash once per second OFF

Test Mode, event detected Flicker OFF

Test Mode, alarm Flash once per second ON 5 seconds