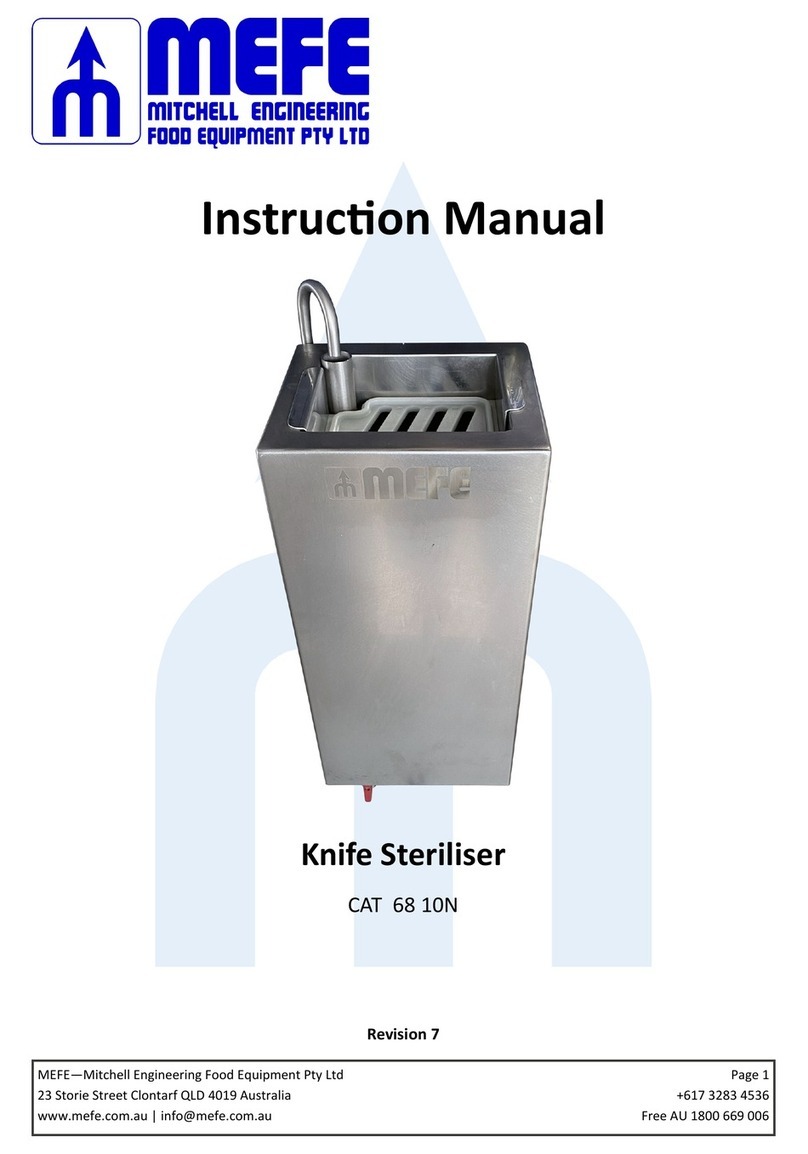

Manuale di uso e manutenzione –Sterilizzatrice a vapore mod. Sterilix Baby

Rev. 03 del 18-04-02 - \\SERVER2012\oo\SETTORE DENTALE\BABY\MANUALI

ISTRUZIONE\Baby GB- R00.doc

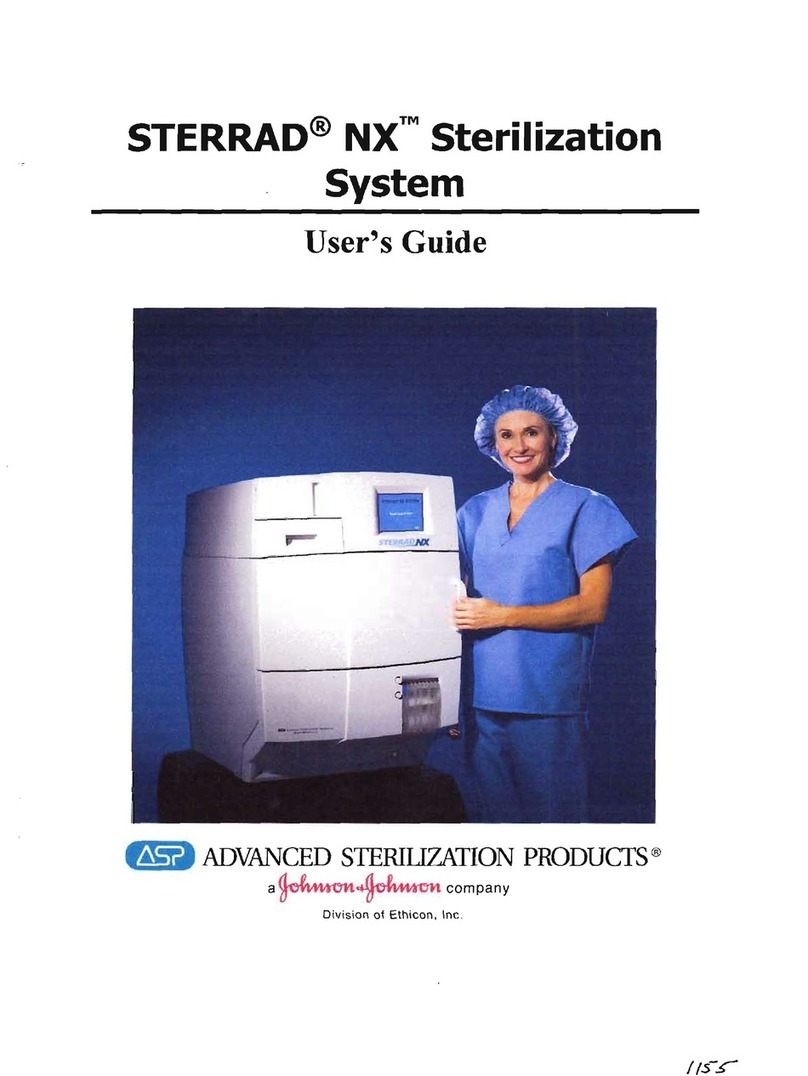

Thanks you for having bought one of its products and asks you to read this manual.

The manual contains all the information you require in order to use the machine you have purchased.

Please carefully comply with the instructions given in the manual and carefully read all its parts.

Keep the manual in a suitable place so that it remains in a perfect condition.

Following improvements or variations to the appliances, the contents of this manual may be liable to

modification without prior notice or other obligations.

This manual contains an installation form which must be fully filled out by the technician when he

installs the machine.

This form will be considered the reference certificate that validates the warranty. It must be sent back

to us along with the printer coupon and warranty form.

Duplication or translation of any part of this manual is forbidden unless prior written authorization has

been obtained from the Manufacturer.

Table of contents:

1. INTRODUCTION .....................................................................................................................................................................3

2. TECHNICAL SPECIFICATIONS...........................................................................................................................................4

3. GENERAL RECOMMENDATIONS ...............................................................................................................................6

3.1 Regulations for the operator...........................................................................................................................................6

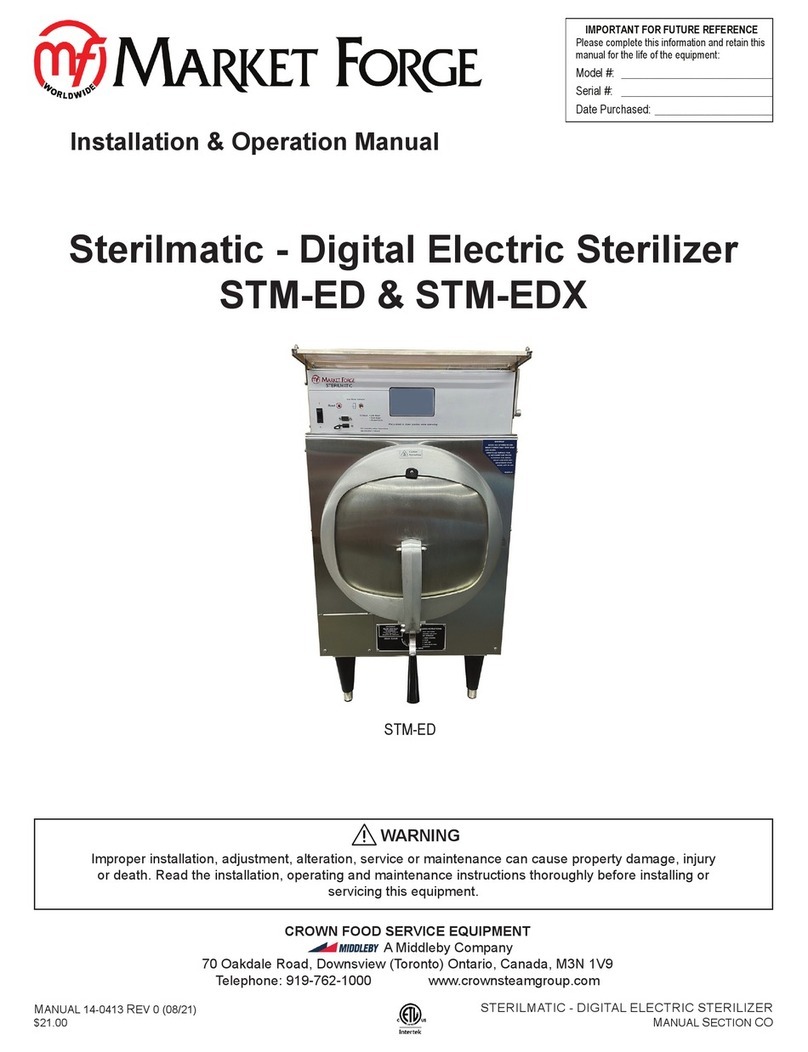

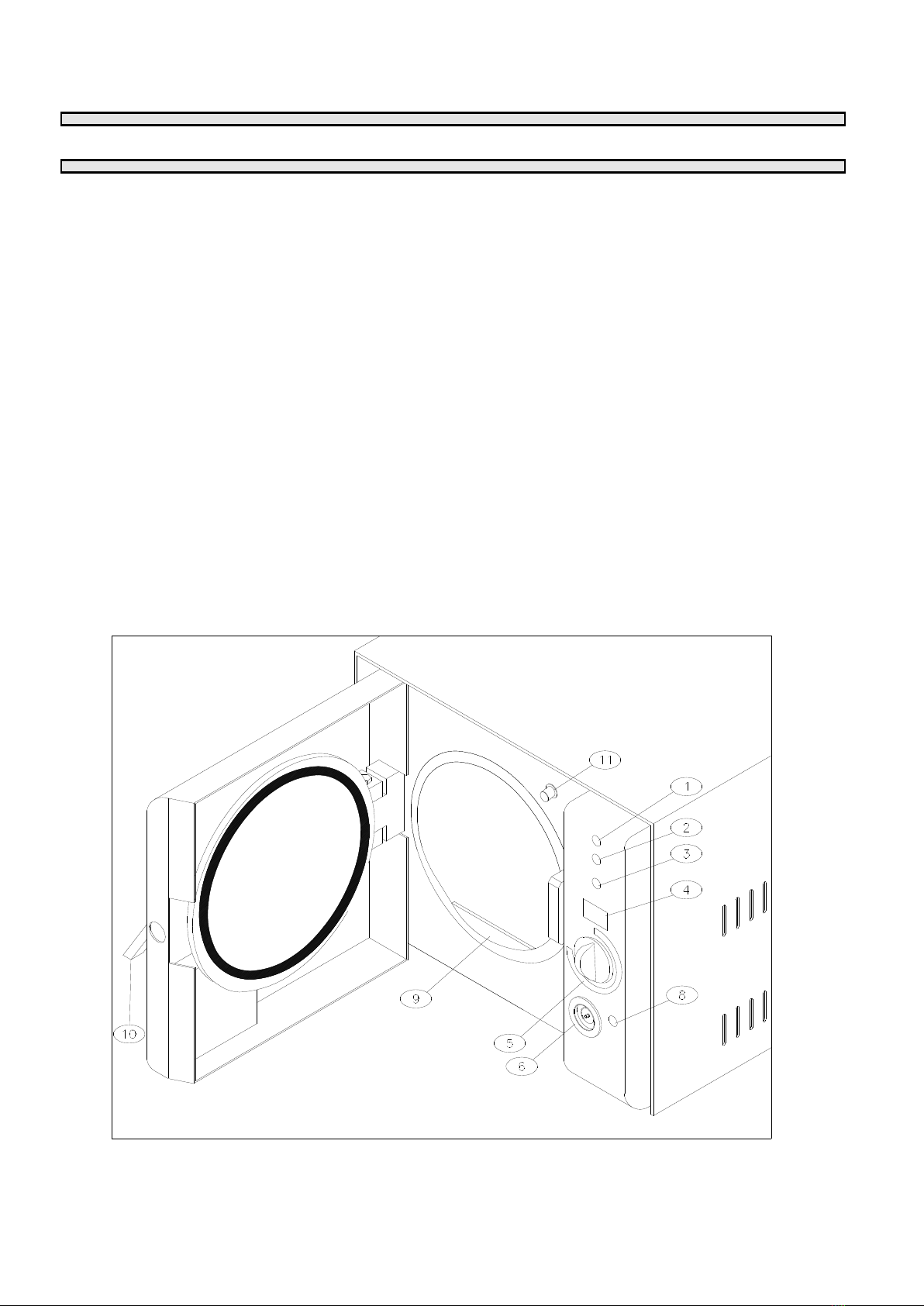

4. LOCATION OF THE CONTROLS..........................................................................................................................................7

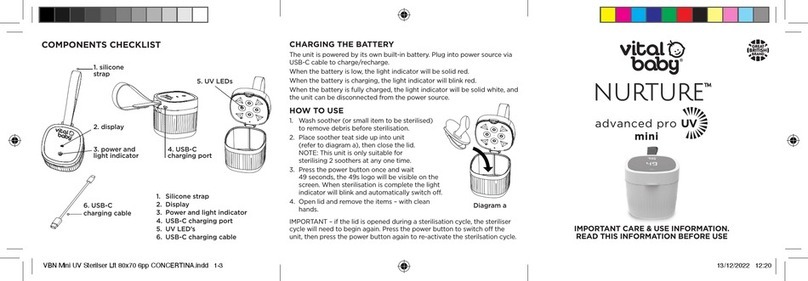

5. STARTING AND SETTING AT WORK..................................................................................................................................9

5.2 Installation and preliminary inspections.......................................................................................................................10

6. GENERAL INSTRUCTIONS FOR USE...............................................................................................................................11

6.1 Method of use....................................................................................................................................................................11

6.2 End of work......................................................................................................................................................................11

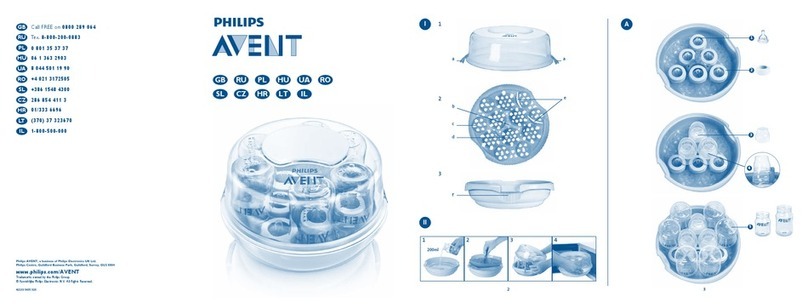

7.HOW TO ARRANGE THE INSTRUMENTS FOR THE STERILIZING PROCESS .........................................................12

7.1 Standard sterilizing...........................................................................................................................................................12

7.2 Sterilzing handpieces........................................................................................................................................................12

7.3 Messaggi visualizzati dal display .......................................................................................................................................12

8. STERILIZING CYCLES.........................................................................................................................................................13

8.3 Sterilizing table ..................................................................................................................................................................13

8.2 Notes and warnings ............................................................................................................................................................14

9. FAULTS ..................................................................................................................................................................................15

9.1 Troubleshooting: Solutions / Remedies.............................................................................................................................15