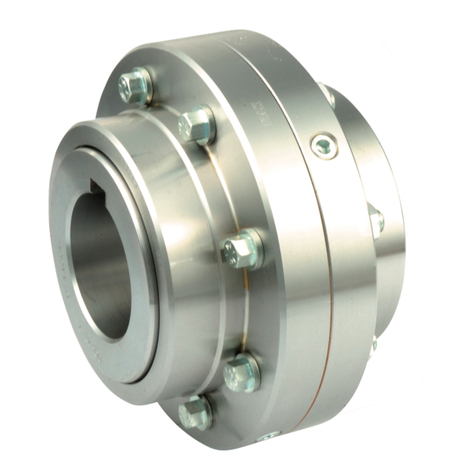

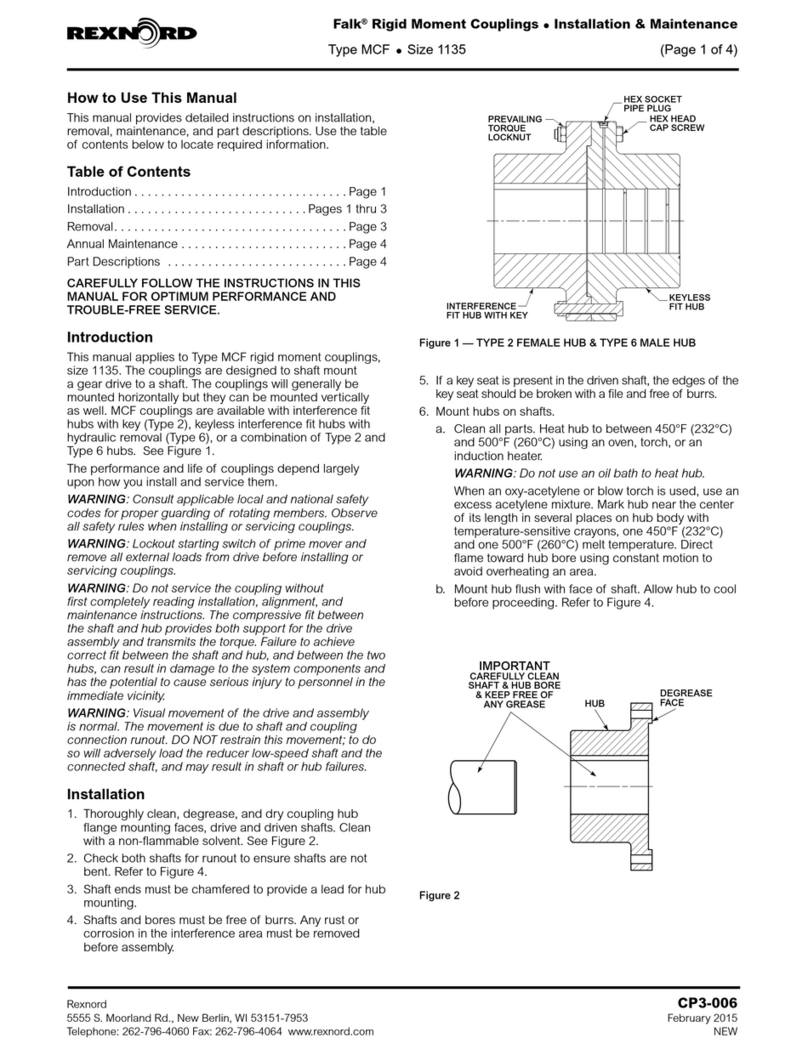

TYPE GL HORIZONTAL COUPLING

INSTALLATION

Only standard mechanics tools, torque wrenches, dial

indicator and feeler gauges are required to install gear

couplings. Clean all parts using a non-flammable solvent.

Check hubs, shafts and keyways for burrs. DO NOT heat

clearance fit hubs. Use a lubricant that meets the specifications

on Page 2 or 3. Pack sleeve teeth with grease and lightly coat

seals with grease BEFORE assembly. The required amount of

grease is listed in Table 4, Page 6. Make certain flange

fasteners are tightened to the required torque listed in Table 4,

Page 6.

Interference Fit Hubs — Unless otherwise specified, gear

couplings are furnished for an interference fit without set screws.

Heat hubs to 275°F(135°C) using an oven, torch, induction

heater or an oil bath. To prevent seal damage, DO NOT heat

hubs beyond a maximum temperature of 400°F (205°C).

CAUTION: To prevent seal damage DO NOT heat hubs

beyond a maximum temperature of 400°F (205°C).

When an oxy-acetylene or blow torch is used, use an excess

acetylene mixture. Mark hubs near the center of their length in

several places on hub body with a temperature sensitive

crayon, 275°F (135°C) melt temperature. Direct flame towards

hub bore using constant motion to avoid overheating an area.

WARNING: If an oil bath is used, the oil must have a flash

point of 350°F (177°C) or higher. Do not rest hubs on the

bottom of the container. Do not use an open flame in a

combustible atmosphere or near combustible materials.

Maximize Performance & Life

The performance and life of couplings depend largely upon

how you install and maintain them. Before installing couplings,

make certain that foundations of equipment to be connected

meet manufacturers’ requirements. Check for soft foot. The

use of stainless steel shims is recommended. Measuring

misalignment and positioning equipment within alignment

tolerances is simplified with an alignment computer. These

calculations can also be done graphically or mathematically.

Balanced Couplings

The fasteners provided are

matched sets and must not be

mixed or substituted. Balanced

couplings are match marked

and must be assembled with

mating match marks aligned.

Component parts of assembly

balanced couplings must not be replaced without re-balancing

the complete assembly.

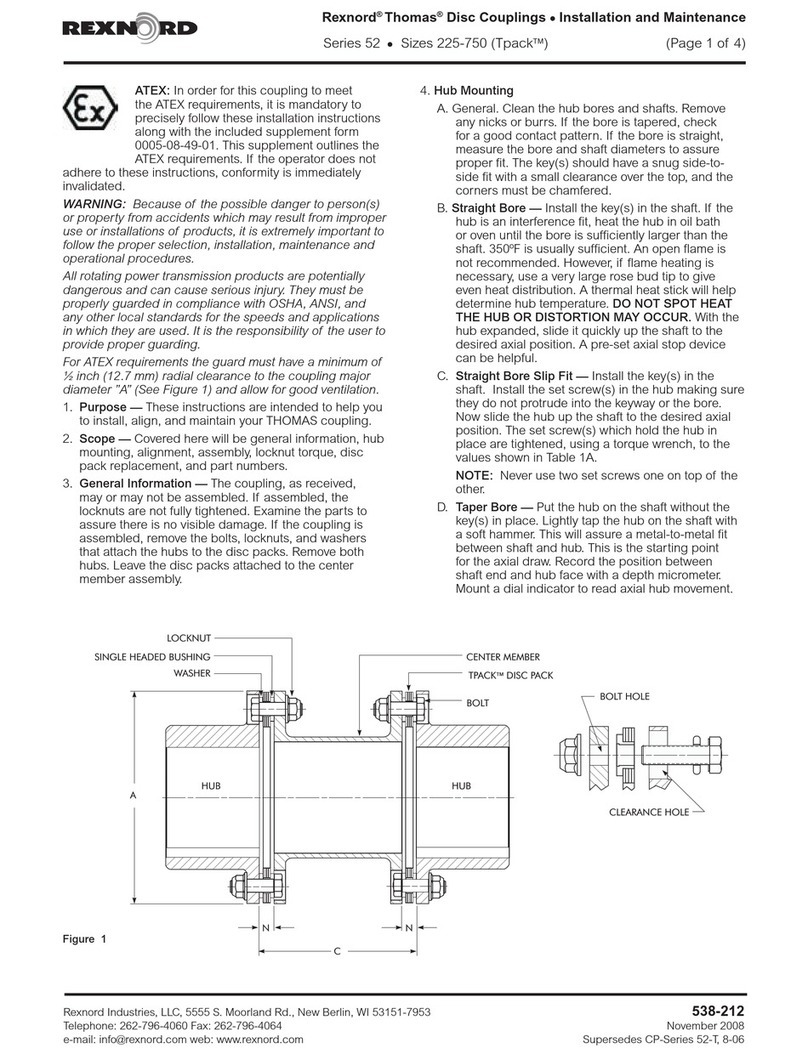

1 — Determine Coupling Assembly Number

Measure flex hub dimension ZG or ZGL, as shown in drawings

on Page 7. Compare the results with the values listed in Table

4 and compare coupling parts provided to the part

identification drawings on Page 7 to determine if coupling is a

GL32-1, GL32-2, or GL32-4. NOTE: GL32-4 couplings are

provided with short tooth sleeves and gap discs.

2 — Mount Flanged Sleeve, Seal & Hubs

Place the flanged sleeves WITH seal rings on shafts BEFORE

mounting hubs.

IMPORTANT: Mount hubs as shown above with SHORT shank,

DIM. ZG or ZGL in Table 4 on Page 6, toward gap. Mount hubs

so that each face is flush with the end of its shaft. Allow hubs to

cool before proceeding. Seal keyways to prevent leakage. Insert

set screws (if required) and tighten. Position equipment in

approximate alignment with approximate hub gap.

3 — Determine Distance Between Hub Ends

Accurately measure spacer length as shown above. To

determine minimum hub gap dimension, add the spacer

length measured, plus the minimum “X” dimension listed in

Table 4 on Page 6. To determine maximum hub gap

dimension, add the spacer length measured, plus the

maximum “X” dimension listed in Table 4 on Page 6.

4 — Gap & Angular Alignment

Adjust gap to any value between minimum and maximum

value calculated in Step 3. Axial movement must never exceed

the minimum and maximum gap values. Temporarily secure

the floating shaft or shafts at their required positions. Use an

inside micrometer as shown above and at 90° intervals to

measure the distance between hubs. The difference in

minimum and maximum measurements should not exceed the

installation ANGULAR limit specified in Table 4 on Page 6.

Rexnord Industries, LLC, Coupling Group458-730

5555 S. Moorland Rd., New Berlin, WI 53151-7953 USA Telephone : 262-796-4060September 1996 (.PDF Revision)

Installation & Maintenance •Falk™ Double Engagement Gear Couplings

(Page 4 of 8) Type GL32 •Sizes 1010 thru 1070

A1 A1 A1 A1 B1 B1 B1 B1

NOTE: SHORTER SHANK

TOWARD GAP END.

NOTE:

FLUSH HERE

SPACER LENGTH