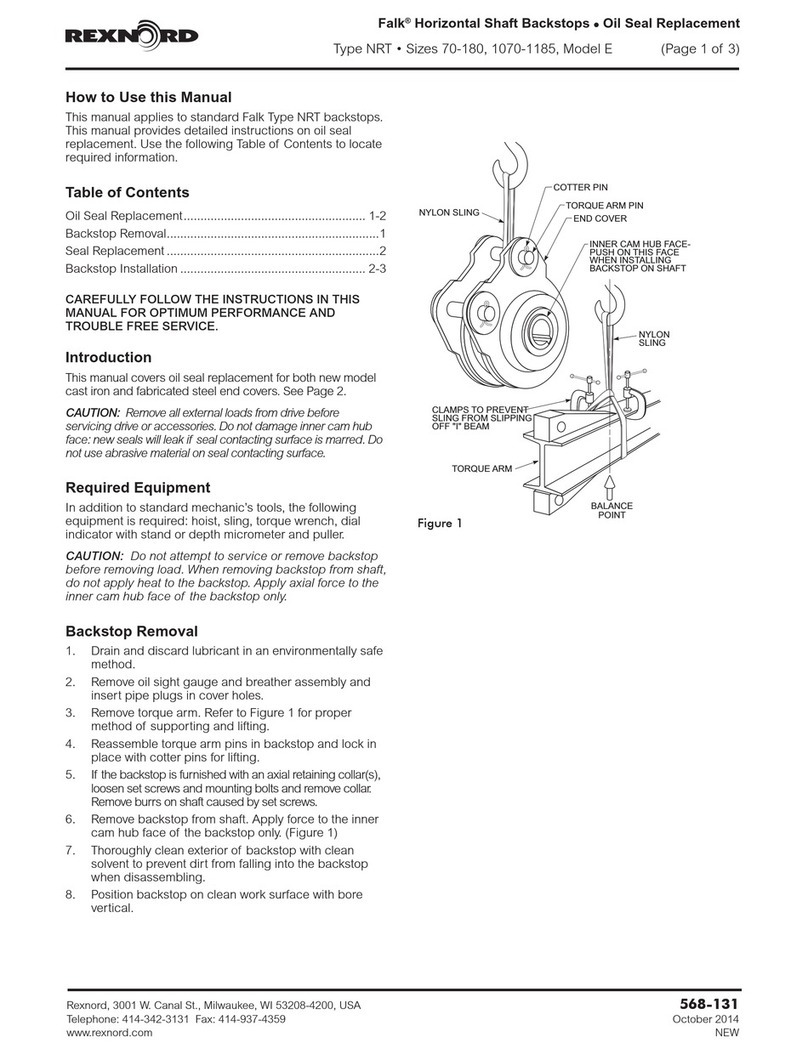

Seal Replacement

13. Check seal surface for any damage prior to installing new

seals. Install one seal at a time. Coat both seal outside

diameters with Permatex #3 or equivalent sealant.

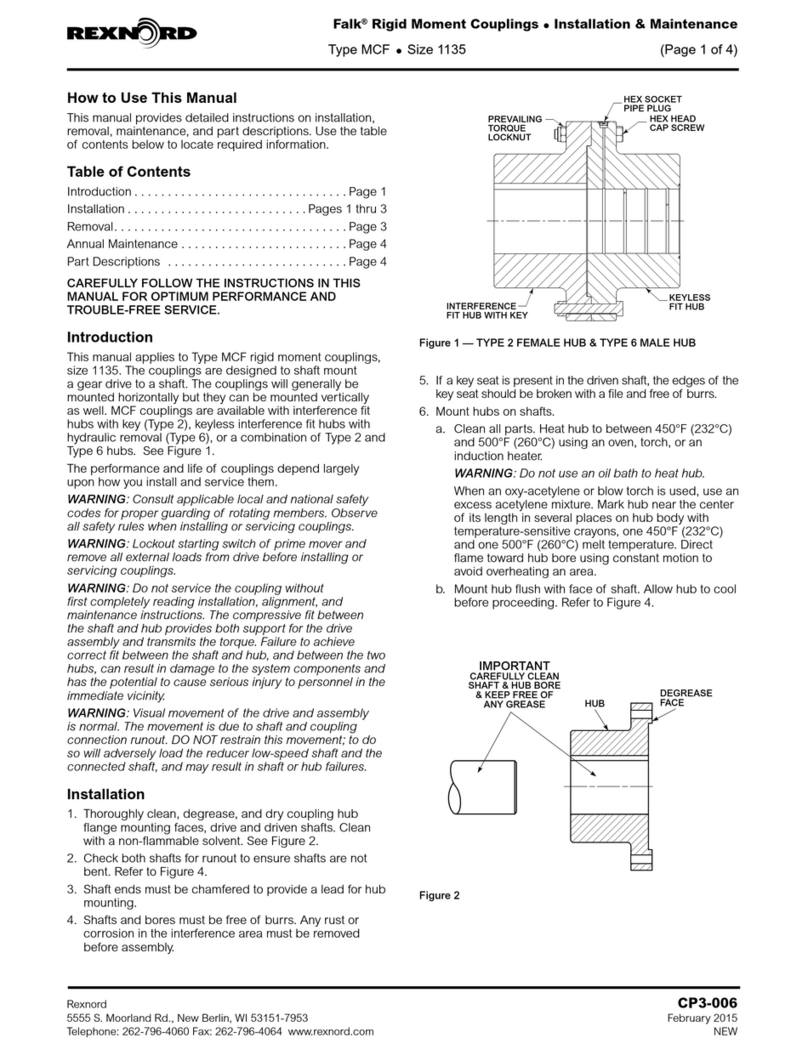

14. OUTER SEAL — Position the outer seal squarely in the end

cover with the garter spring positioned per Figure 3.

NOTE: Use seal with smaller outer diameter as outer seal

for Sizes 130 thru 170 and Sizes 1130 thru 1175.

15. Place a square ended cylindrical tool against the seal and

press or lightly tap the tool (not the seal) until the seal is

seated against the shoulder. (Figure 3)

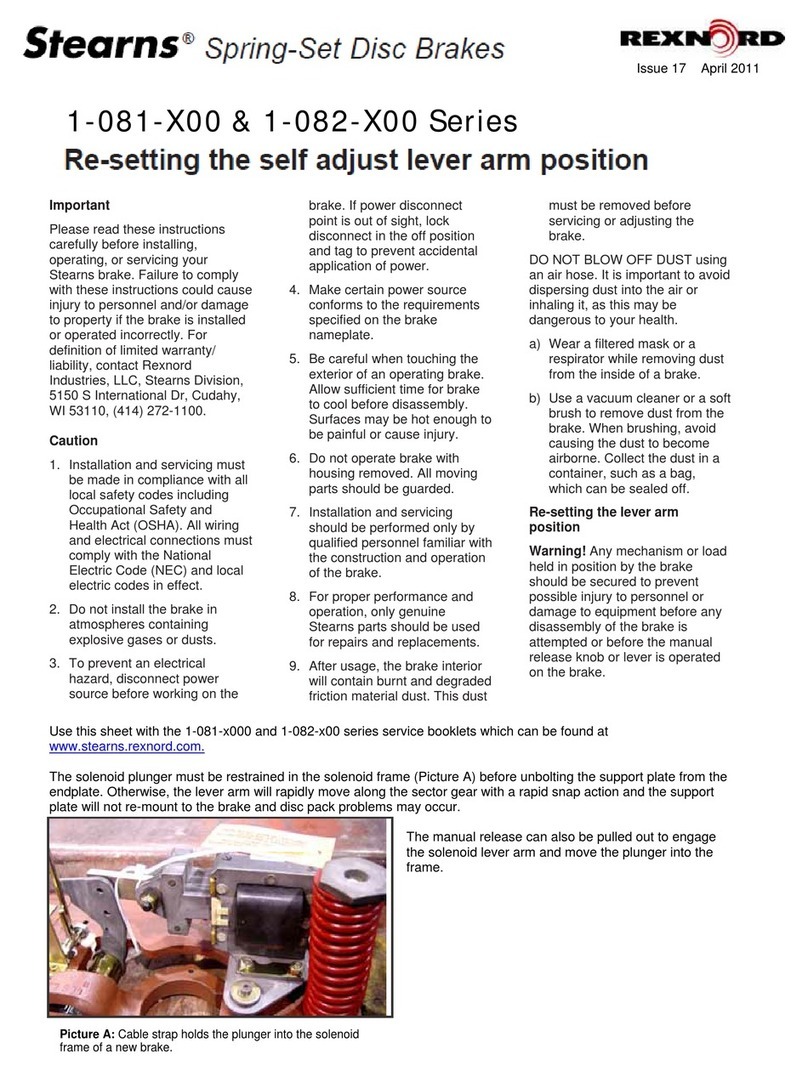

16. Check seal runout with a depth micrometer, dial indicator

or bar micrometer as shown in Figure 4. Runout must not

exceed .010” (0.25mm) TIR.

17. INNER SEAL — Install the inner seal per Steps 15 and 16

and as follows:

Sizes 70 thru 120 & Sizes 1070 thru 1125 — Install to

depth shown in Figure 3.

Sizes 130 thru 170 & Sizes 1130 thru 1175 — Seat as

shown in Figure 3.

Size 180 & Sizes 1180 thru 1185 — Seals have built-in

spacer lugs. Lugs of inner seal are to be in contact with

case of outer seal.

Backstop Assembly

18.Coat seal lips and chamber between seals with NLGI#2

grease. Hand pack grease cavity between inner and outer

seal with NLGI#2 grease. Reinstall end cover and the

same number of new gaskets as noted in Step 10. Do not

use gaskets made from substitute material; use only the

new gaskets furnished by the Factory.

19.Reinstall end cover fasteners but do not tighten; this will

facilitate torque arm pin assembly.

20.Turn backstop over and replace seals in opposite end

cover per Steps 9 thru 19.

21.Align end covers by inserting torque arm pins. Tighten all

end cover fasteners to the torque shown in Table 1.

Backstop Installation

22.Refer to Manual 568-110 for backstop installation, oil sight

gauge assembly and lubrication recommendations.

BACKSTOP SEAL REPLACEMENT — For Backstops

with Fabricated Steel End Covers, See Figures 4,5, and 6 on

Page 3.

CAUTION: Remove all external loads from drive before

servicing drive or accessories. Do not damage cam or hub

face: new seals will leak if seal contacting surface is marred.

Do not use abrasive material on seal contacting surface.

1. To prevent dirt from falling into the backstop, thoroughly

clean exterior of backstop with clean non-flammable

solvent.

2. If removing backstop, refer to BACKSTOP REMOVAL on

Page 1.

3. Remove labyrinth shroud (See Figure 7, Page 3) from

backstop. Clean cam or hub face with solvent and remove

all sharp edges. Use a sharp center punch to lightly punch

the seal case as a guide for the drill. Check seal surface

for any damage prior to installing new seals.

4. Wrap several turns of tape around the drill approximately

.250” (6mm) from the drill point to prevent the drill from

entering too deeply into the housing and damaging the

bearing (inner seal only). Grease or magnetize the drill to

help retain the chips. Drill two .125” (3mm) diameter holes

Rexnord Industries, LLC, Geared Products, P.O. Box 492, Zip 53201-0492568-130

3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131February 2009

Fax: 414-937-4359 e-mail: info@rexnord.com web: www.rexnord .comSupersedes 11-01

Oil Seal Replacement •Falk™ Horizontal Shaft Backstops

(Page 2of 3) Sizes 70-180, 1070-1185 •Types NRT

GARTER

OUTER

SEAL

SEAT

.12” (3mm) APPROX.

CLEARANCE

SIZES 70 THRU 120

SIZES 1070 THRU 1125

SIZES 130 THRU 170

SIZES 1130 THRU 1175

GARTER

SPRINGS

OUTER

SEAL

SEAT INNER SEAL SEAT

INNER SEAL (SEAT

AGAINST LUG)

GARTER

SPRINGS

SIZE 180

SIZES 1180/1185

OUTER

SEAL

SEAT

INNER

CAM

INNER

CAM

INNER

CAM

Figure 3

PARALLEL

SEAL

END COVER

DEPTH

MICROMETER

Figure 4

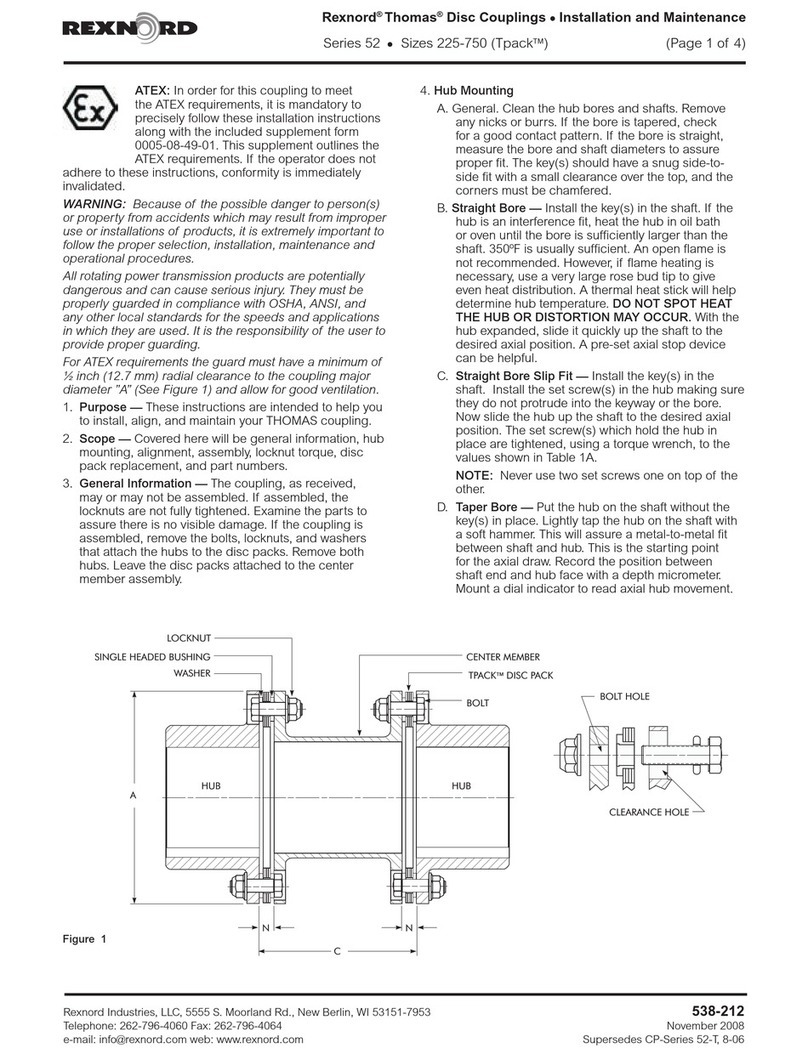

TABLE 1 — End Cover Fastener

Tightening Torque

Backstop

Size

Grade8

Cap screw Size

Tightening Torque H

lb-in (Nm)

70 & 1070/1075 .500”-13UNC 1,325(150)

80 & 1080/1085 .500”-13UNC 1,325(150)

90 & 1090/1095 .500”-13UNC 1,325(150)

100 & 1100/1105 .500”-13UNC 1,325(150)

110 & 1110/1115 .625”-11UNC 2,550(290)

120 & 1120/1125 .625”-11UNC 2,550(290)

130 & 1130/1135 .750”-10UNC 4,425(500)

140 & 1140/1145 .750”-10UNC 4,425(500)

150 & 1150/1155 .875”-9UNC 7,100(800)

160 & 1160/1165 .875”-9UNC 7,100(800)

170 & 1170/1175 .875”-9UNC 7,100(800)

180 & 1180/1185 1.000”-8UNC 10,400(1180)

HDo not oil fasteners and locknuts or use Loctite compound.