How to Use this Manual

The following instructions and recommendations apply to

standard Falk 1055, 1065, & 1085 NRTH Style B backstops.

Their performance and life depend largely upon how they are

installed and serviced. Drawings are representative of this

series of backstops.

When requesting information specify the M.O. number,

backstop size, model number, maximum running rpm, torque

rating, and date indicated on the backstop nameplate.

This manual provides detailed instructions on installation,

maintenance, and parts identification. Use the following Table

of Contents to located required information.

Table of Contents

General Information .........................Page1

Description and Operation ....................Page1

Safety Codes and General Precautions............Page1

Application Requirements ....................Page1-2

General Instructions .........................Page3

Long Term Storage ..........................Page3

Installation ..............................Page3-4

Lubrication ...............................Page4

Maintenance ..............................Page4

CAREFULLY FOLLOW THE INSTRUCTIONS IN THIS

MANUAL FOR OPTIMUM PERFORMANCE AND TROUBLE

FREE SERVICE.

Introduction

Rexnord True Hold backstops are precision built safety devices

designed to protect inclined conveyors or vertical elevators

from the dangers of gravity accelerated reverse runaway. To be

assured of reliable protection and the longest possible service

life, it is important that the following recommendations be

observed for the installation, lubrication, and maintenance of

Rexnord backstops.

As soon as the backstop has been received, examine it

carefully for damage that may have occurred in transit and

report any breakage to the transit company and Rexnord

immediately. All tags and bulletins attached to the backstop

should be carefully read before placing the backstop in

operation and then filed for future reference.

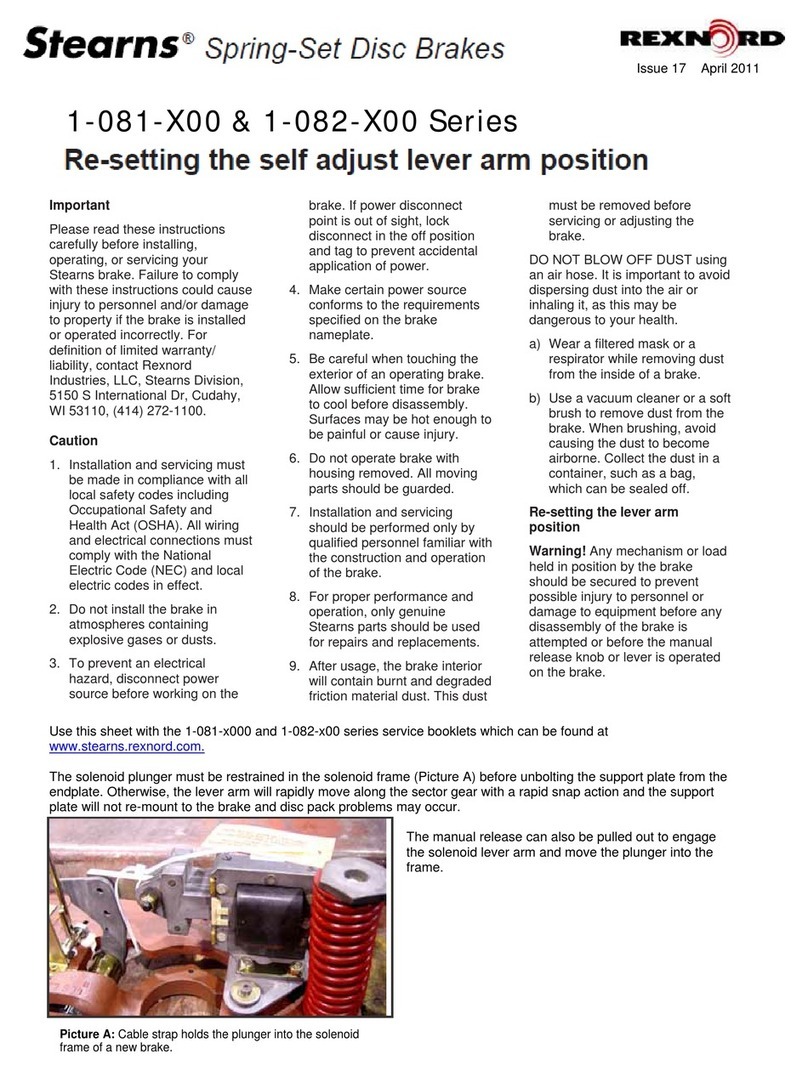

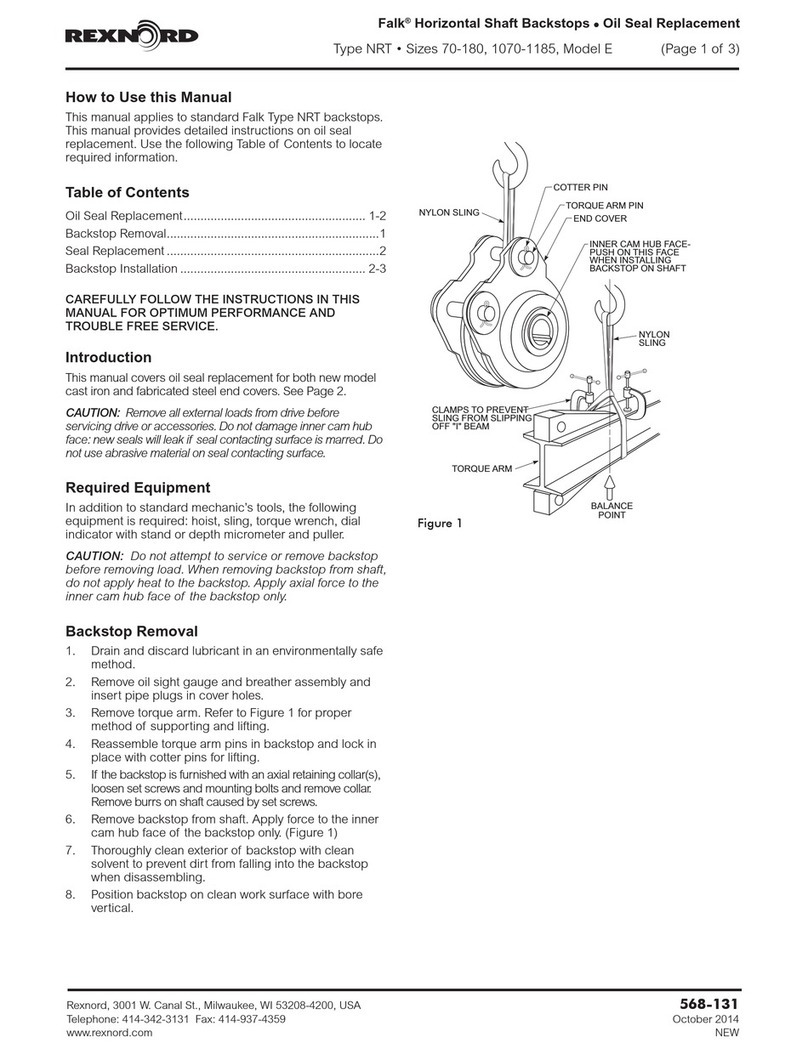

The various component parts referred to may be readily

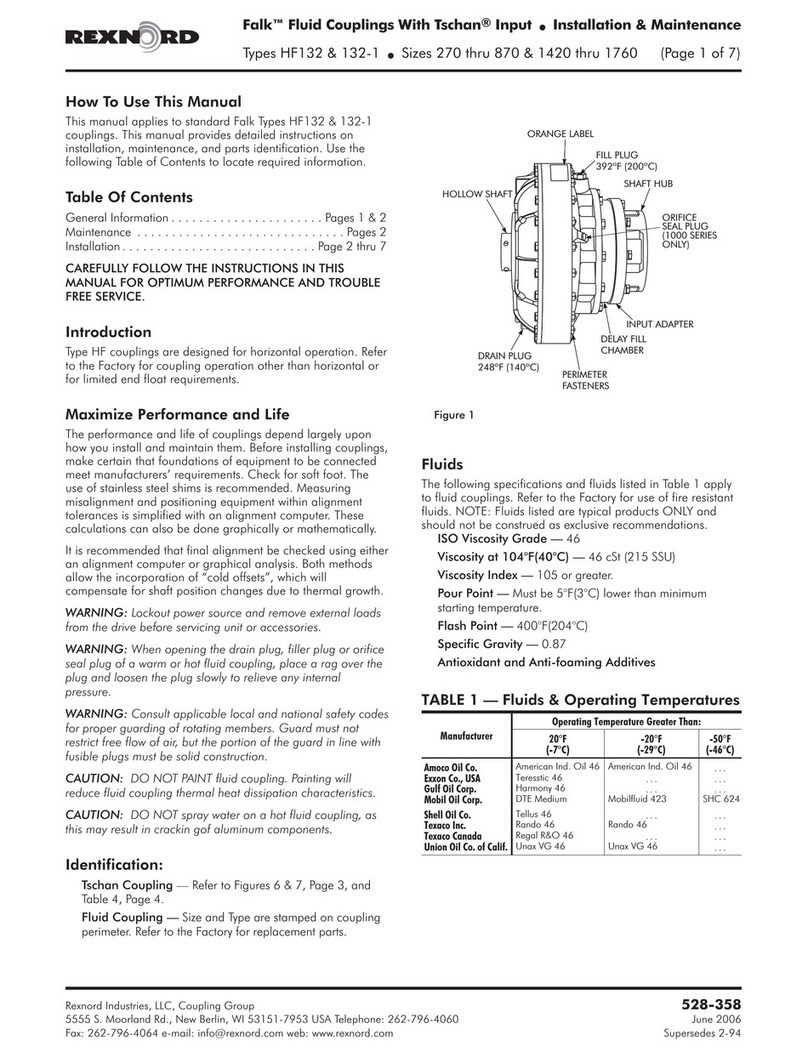

identified from Figure 1 on Page 2.

ALL BACKSTOPS ARE SHIPPED WITH OIL — Although all

backstops are shipped from the factory with oil, it is important

to check lubrication levels prior to operation.

If the backstop is to be stored for an extended period of time

(over 3 months) before installation, see the Long Term Storage

section on Page 3 for instructions.

Warranty — Rexnord Industries, LLC (the ”Company”)

warrants that Drive One gear drives (I) conform to Company’s

published specifications, and (II) are free from defects of

material for three years from the date of shipment.

Company does not warrant any non-Company branded

products or components (manufacturer’s warranty applies) or

any defects in , damage to, or failure of products caused by:

(I) dynamic vibrations imposed by the drive system in which

such products are installed unless the nature of such vibrations

has been defined and accepted in writing by Company as a

condition of operation; (II) failure to provide suitable

installation environment; (III) use for purposes other than those

for which designed, or other abuse or misuse; (IV)

unauthorized attachments, modifications or disassembly, or (V)

mishandling during shipping.

Safety Codes & General Precautions

Warning: Consult applicable local and national safety codes

for proper guarding of rotating members. Lock out power

source and remove all external loads from drive before

servicing drive or accessories.

DISMANTLING, REPAIR & PARTS REPLACEMENT — See

Figure 1, Page 2. The backstop and normal associated

equipment (shaft, pulleys, etc.) involve moving parts, therefore

consult local, state, OSHA and ANSI safety codes for proper

guarding of revolving parts and possible pinch points. (A pinch

point occurs at the contact point between the backstop torque

arm and support, and between the torque arm and stirrup.)

Carefully read and follow all supplementary instructions and

tags attached to the backstop and then file for future

reference.

Operate the backstop within the torque rating and overrunning

speed, listed on the nameplate. Follow installation and

lubrication instructions in this manual.

When removing backstop from shaft, do not apply heat to the

backstop. Apply axial force to the hub (inner race) of the

backstop only.

Damage may occur to the backstop if it remains inoperative

under full load for extended periods of time.

If the shaft was accidentally rotated in the wrong direction of

rotation at start-up, the backstop may have been damaged.

Return the backstop to the Factory for inspection.

Falk NRTH Style B backstops use a sprag design that does not

allow motion in one direction and runs freely in the other

direction.

Application Requirements

BACKSTOP APPLICATION — The 1055, 1065, & 1085

NRTH Style B backstops are designed to prevent reverse

rotation in applications such as inclined conveyors, bucket

elevators, fans, rotary pumps and kilns. If local safety codes

permit, the backstop may be used as a backup or a brake on

these applications, but NOT in people conveying systems such

as elevators, manlifts, ski tows or ski lifts. Also DO NOT use

the backstop as a substitute for a brake.

OPERATING TEMPERATURES — Enclosure of the backstop

may cause overheating. Provide adequate ventilation.

Backstop operating temperatures, at maximum overrunning

speed, may exceed 90°F (50°C) above ambient. Determine

the effect of this temperature on the driven equipment and

provide cooling if necessary.

If a backstop operates in the sun at ambient temperatures over

100°F (38°C), then special measures should be taken to

protect the backstop from solar energy. This protection can

consist of a canopy over the backstop or reflective paint on

Rexnord Industries, LLC, Geared Products, P.O. Box 492, Zip 53201-0492 568-102

3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131 July 2006

Falk™ Horizontal Shaft Backstops •Installation & Maintenance

Type NRTH Style B •Sizes 1055, 1065, & 1085 (Page 1 of 4)