Form O-CAUA, Page 2

2. MAINTENANCE A Model CAUA will operate with a minimum of maintenance. To ensure long life

and satisfactory performance, a heater that is operated under normal condi-

tions should be inspected and cleaned at the start of each heating season. If

the heater is operating in an area where an unusual amount of dust, soot, or

other impurities are present in the air, more frequent maintenance is recom-

mended. If the system includes a cooling coil, the coil and condensate drains

should be checked at the beginning of the cooling season.

The paragraphs that follow discuss the components and systems that require

routine inspection/maintenance. At the beginning of each section, there is a

code indicating the main reason why that maintenance procedure is neces-

sary. The legend for that code is shown on the left.

WARNING: If you

turn off the power

supply, turn off the

gas. See Hazard

Levels, Page 2.

HAZARD INTENSITY LEVELS

1. DANGER: Failure to comply will result in severe personal injury or death

and/or property damage.

2. WARNING: Failure to comply could result in severe personal injury or

death and/or property damage.

3. CAUTION: Failure to comply could result in minor personal injury and/or

property damage.

1. General The operation/maintenance/service instructions in this manual apply to Reznor®

Model CAUA upow, separated-combustion, gas-red heater. As with any gas-

burning equipment, regular maintenance procedures are required to ensure

continued safety, reliability, and efciency of the installation.

If service is required, this heater should be serviced only by a qualied service

technician. Service information is this booklet is intended as a guideline for a

qualied gas-red equipment service technician.

2.1 Maintenance

Schedule

The following procedures should be carried out at least annually. Follow the

instructions in Paragraph 2.2.

• Clean the blower and motor. If equipped with a belt drive, check the belt.

• Check the lters.

• Check the gas valve to ensure that gas ow is being shutoff completely.

• Check the burners for scale, dust, or lint accumulation.

• Check the ignitor

1. General ....................................................2

2. MAINTENANCE ....................................2-7

2.1 Maintenance Schedule..................... 2

2.2 Maintenance Procedures.................. 3

2.2.1 Blower and Blower Motor .........................3

2.2.2 Filters ........................................................3

2.2.3 Gas Valve..................................................4

2.2.2 Filters (cont'd)............................................4

2.2.4 Burner Maintenance..................................5

2.2.5 Ignition System..........................................6

2.2.6 Cleaning the Heat Exchanger ...................7

2.2.7 Venter Motor and Wheel ...........................7

2.2.8 Vent or Vent/Combustion Air System ........7

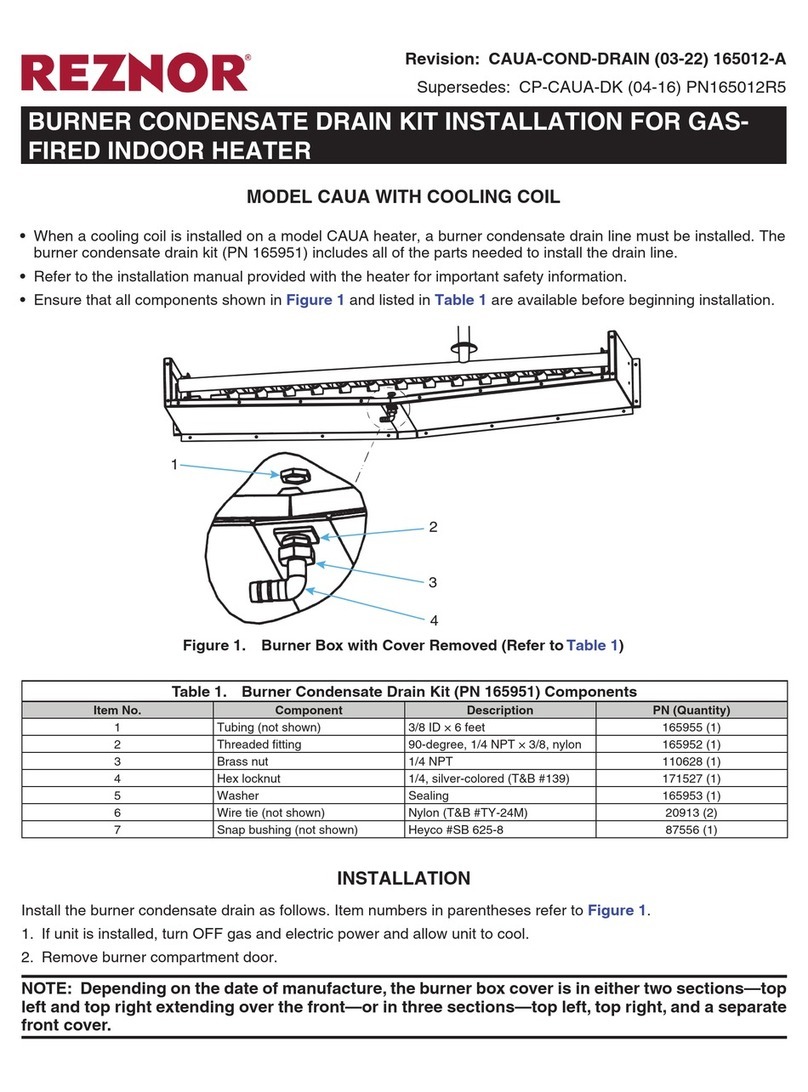

2.2.9 Condensate Drain .....................................7

3. SERVICE - Control Location,

Operation, and Service......................7-15

3.1 Control Locations.............................. 8

3.2 Heater Rating Plate .......................... 8

3.3 Service Procedures .......................... 8

3.3.1 Operating Gas Valve .................................8

3.3.2 Ignition System..........................................8

3.3.3 Combustion Air Proving Switch.................9

3.3.3 Limit Control ............................................10

3.3.4 Flame Rollout Switch ..............................10

3.3.5 Venter Motor and Wheel Assembly .........10

3.3.6 Transformer.............................................11

3.3.7 Blower Motor and Drive...........................12

3.3.8 Blower Compartment Door Switch .........12

3.3.9 Inlet Air Dampers and Controls ..............12

3.4 Troubleshooting.............................. 14

INDEX.........................................................16

REFERENCES ...........................................16

TABLE OF CONTENTS