3/31

1.0 Introduction

1.1 General

1.1.1 Before installation check that the appliance as

described on the packaging label is in

accordance with the correct type and model

specified on the data plate and complies with

your customer order.

1.1.2 The heater is delivered wrapped in heavy duty

polythene and should be checked to ensure

that it has been delivered undamaged.

1.1.3 Please read this document before commencing

installation. The onus rests with the installer to

ensure that all relevant manuals are read and

understood, especially with regard to any

safety instructions stipulated by the

manufacturer.

1.1.4 These instructions are only valid for the country

of use indicated on the appliance, i.e. GB - IE.

If these symbols are not shown it is necessary

to obtain appropriate technical instructions

which will provide information concerning the

necessary modification of the appliance for use

in the country concerned. Such instructions

may be obtained from your supplier upon

request.

1.1.5 Check that the local distribution conditions of

electricity supply, type of oil and pressure and

adjustment of the appliance are compatible.

1.1.6 When installed in Great Britain the total

installation must comply with the requirements

and recommendations of the relevant British

Standards & local laws. The installation must

also be in accordance with the relevant

electrical regulations and I.E.E. regulations.

1.1.7 Warning! Unauthorised modification of this

appliance or departure from use in the manner

for which it was intended by the manufacturer,

or installation in a manner contrary to these

instructions may constitute a hazard and

jeopardise all warranties. Deviations should

only be carried out after formal consent has

been obtained from the manufacturer.

1.1.8 Caution! Ensure that the environment in which

the air heater is to be installed will not create a

hazard, i.e. where excessive (volatile) dust,

flammable or corrosive substances and/or

vapours and combustible materials may be

present. Suitable protection should be given to

prevent damage to the appliance, for example

from fork lift trucks.

1.1.9 These appliances have been tested and set

according to the data plate before leaving the

factory.

1.2 Quality Products

1.2.1 The Reznor range of oil fired floorstanding

heaters is manufactured in the EC and

supplied in accordance with BS EN 9002: 1994

Quality Assurance System.

1.2.2 Certificates of conformity are available from the

Quality Control department at Reznor Limited.

1.3 CE-Approval-European

Directives

1.3.1 Reznor floorstanding heaters have been fully

assessed and tested and meet the following

EC Directives:

- Machinery Directive (89/392/EEC)

- Low Voltage Directive (73/23/EEC &

93/68/EEC)

- Electromagnetic Compatibility Directive

(89/336/EEC & 91/36 EEC)

- Product Liability Directive (65/379/EEC)

1.3.2 In addition Reznor oil fired floorstanding

heaters are conform to the following

harmonised standards:

BS EN 292 - Part 1 :Safety of Machinery -

Basic Concepts, General Principles for

terminology, methodology

BS EN 292 - Part 2 :Safety of Machinery -

Basic Concepts, General Principles for Design

Technical Principles and Specifications.

BS EN 60204 - Part 1 :Safety of Machinery -

Electrical Equipment for Machine Specification

for General Requirements.

BS EN 60335 - Part 1 :Safety of Household

and Similar Electrical Appliances General

Requirements.

BS EN 55014 :Limits and methods of

measurement of radio disturbance

characteristics of electrical motor-operated and

thermal appliances for household and similar

purposes, electric tools and similar electric

apparatus.

prEN 50165 :Electrical equipment of non-

electric heating appliances for household and

similar purposes, safety requirements.

1.4. Product Information

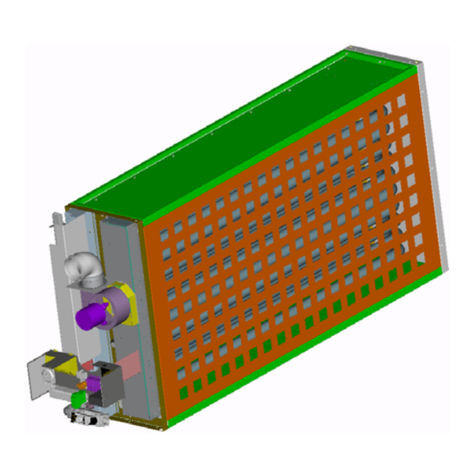

1.4.1 Reznor floorstanding heaters are available with

burner outputs from 30kW to 293kW and can

be floor mounted (FSV units) or suspended

(FSH units).

Floorstanding heaters can be used in free

blowing or ducted applications. Each heater

must have its own individual open flue.

1.4.2 All floorstanding heaters are fitted with a pre-

tested and set forced draught burner. A

sequential control box is fitted to each burner

to provide safety. Note: No asbestos or

soldered joints are present in the construction

of the heater.

1.4.3 All the materials selected can withstand the

range of chemical, mechanical and thermal

demands expected during the foreseen and

normal use of the product, as stipulated by

manufacturers' instructions and

recommendations.

1.4.4 Before final location of the product the following

criteria should always be considered in placing

the heater:-

• Flue outlet access

• Placing for efficient distribution of warm air

• Oil supply

• Electrical services

• Fresh air supply (when applicable)

• Service access and maintenance

requirements

1.5 Warning

Heaters should not be installed in a corrosive

or solvent atmosphere

(i.e. near plating or degreasing plants), in areas

where there is a fire risk, or any other

environment which is detrimental to the heater

or its operation. Consult BS 6230 for further

information on hazardous areas.