Page No 4 of 56 Reznor, RHC21 4000 Installation EN May 2021 D301334 Issue 0

In instances where copper pipework is to

be used for all or part of a gas pipework

installation, including short length final

connections then we advise that installers

consult with the gas supplier or provider and

satisfy themselves what additional precautions

may be necessary.

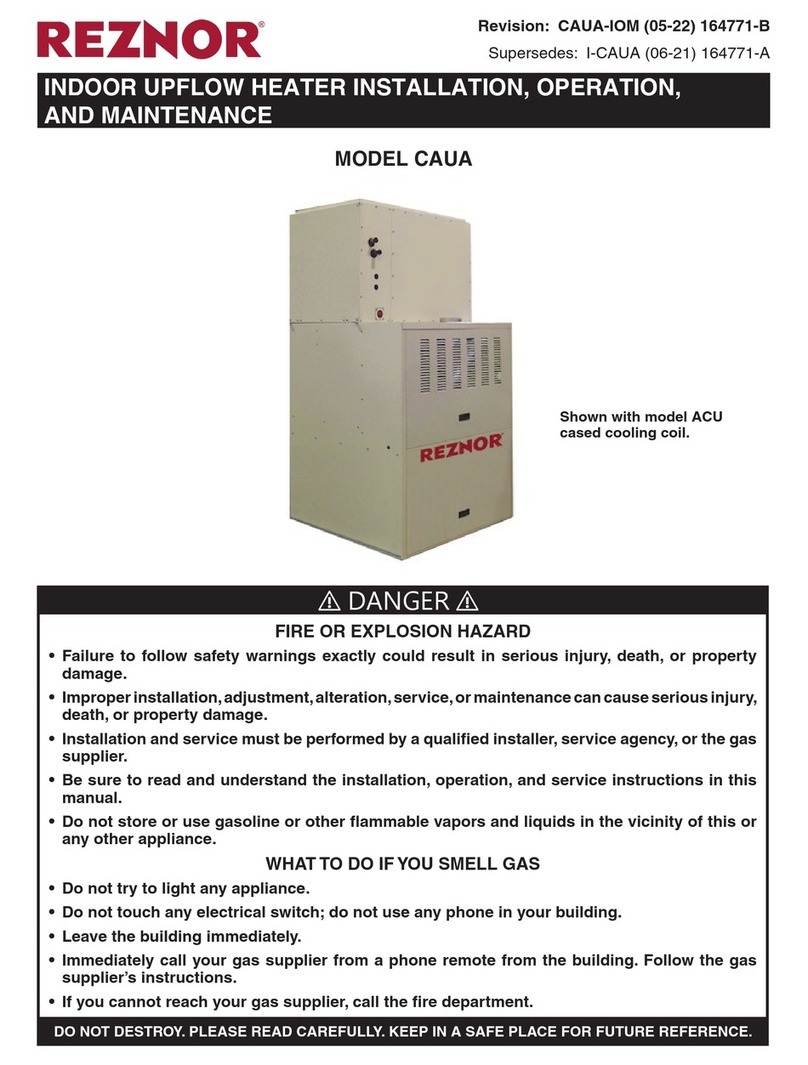

Improper installation, adjustment,

alteration, service, or maintenance

can cause property damage,

injury, or death. Read the

installation, operation, and

maintenance instructions

thoroughly before installing or

servicing this equipment.

Gas-fired appliances are not designed for

use in hazardous atmospheres containing

flammable vapours or combustible dust,

in atmospheres containing chlorinated or

halogenated hydrocarbons or in applications

with airborne silicone substances.

Any reference made to Laws, Standards,

Directives, Codes of Practice or other

recommendations governing the application

and installation of heating appliances and

which may be referred to in Brochures,

Specifications, Quotations, and Installation,

Operation and Maintenance manuals is done

so for information and guidance purposes only

and should only be considered valid at the

time of the publication.

The manufacturer cannot be held responsible

from any matters arising from the revision

to or introduction of new Laws, Standards,

Directives, Codes of Practice or other

recommendations.

The temperature in the controls section of the

unit must never be less than -10°C otherwise

damage could occur to the sealing elements of

the gas valve and to the electrical components.

The electrical isolator should only be used in an

emergency and should not be used for closing

down the main burner, as it switches off the

fan prematurely and may damage the heat

exchanger, invalidating the warranty.

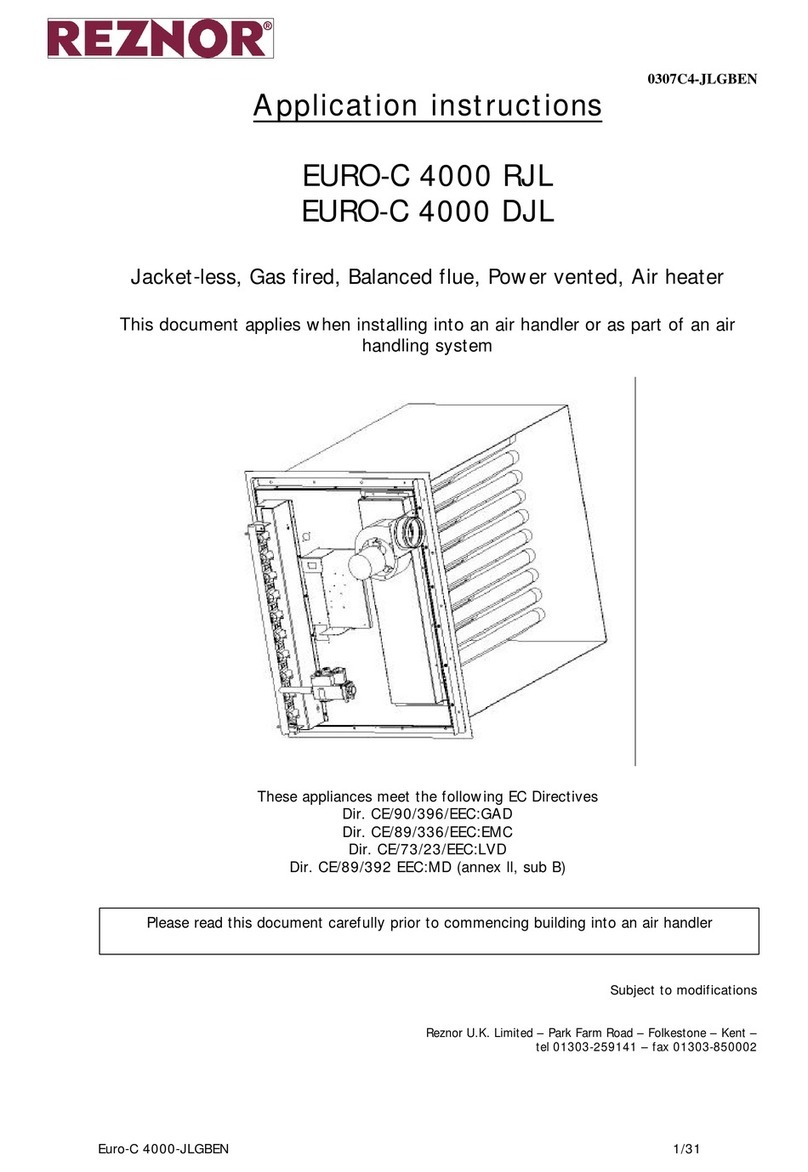

Important notice to

installers

Before installation, carefully read these

instructions and follow the processes explained

by the manufacturer. These instructions are

only valid for appliances designed to operate in

Europe. If the country code and gas category

on the appliance data label does not match

the country of installation or the country codes

and gas categories as shown in this instruction

manual, it will be necessary to contact the

distributor or manufacturer to provide the

necessary information for the modification of

the appliance to the conditions of use for the

country of installation.

Installing, commissioning, testing,

programming and maintenance of these

products must only be carried out by suitably

qualified and trained technicians and in full

compliance with all applicable regulations and

current best practices.

Check if the appliance as described on the

packaging label is in accordance with the

correct type and model as specified on the

data plate and complies with your customer

order.

Check that the temperature ranges given

and those of the location match. The

appliance must be powered with a voltage

corresponding to the value shown on the

rating plate.

These units must be installed in accordance

with the rules in force and local regulations /

legislation as appropriate plus all local building

codes. Installers should satisfy themselves that

the gas pipework installation is carried out in

accordance with all current legislation, Codes

of Practice and recommendations.

Additionally it may be necessary to protect

the gas valves which form part of the heater

or burner assembly from potential pipe

contamination particularly, but not exclusively,

where copper gas pipework is used.