TABLE OF CONTENTS

CHAPTER TITLE PAGE

RGC MARINE PRODUCTS 11/16/99 PHONE: (716) 895-1156

1 SAFETY.................................................................................................................................1

1.1 Introduction.............................................................................................................................1

1.2 Safety Definitions....................................................................................................................1

1.3 Equipment Safety Labels.........................................................................................................1

1.4 Equipment And Personnel Safety ...........................................................................................1

1.5 Installation Safety....................................................................................................................2

1.6 Operating Safety......................................................................................................................2

1.6.1 General ....................................................................................................................................2

1.6.2 Safety When Raising the Boat.................................................................................................3

1.6.3 Safety When Lowering the Boat .............................................................................................3

1.7 Maintenance and Storage Safety .............................................................................................3

2 SPECIFICATIONS...............................................................................................................5

2.1 Technical Data.........................................................................................................................5

2.2 Nameplate and Serial Number Tag..........................................................................................5

2.3 Optional Equipment.................................................................................................................5

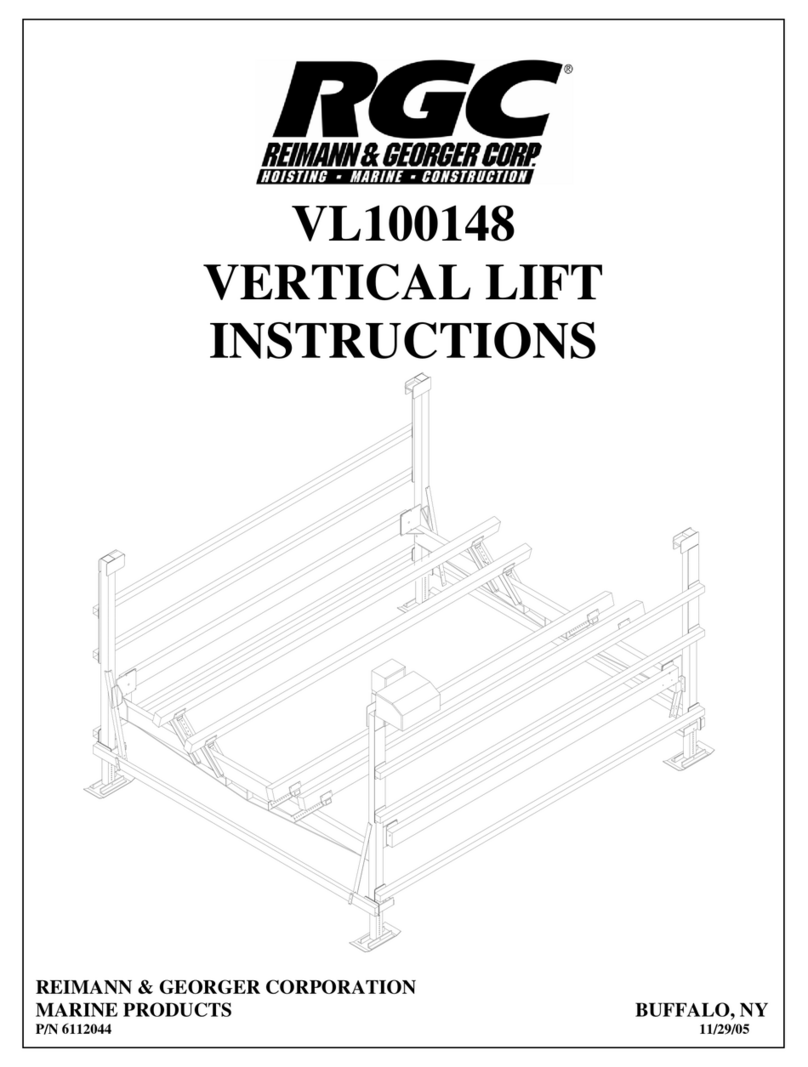

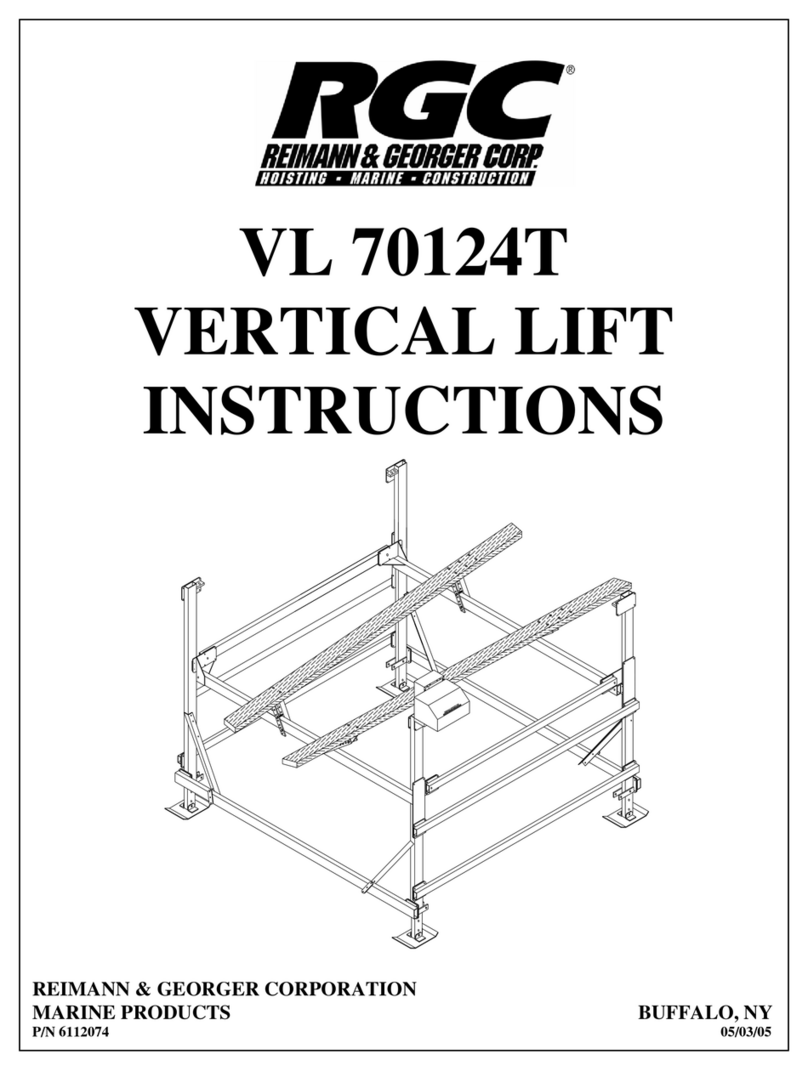

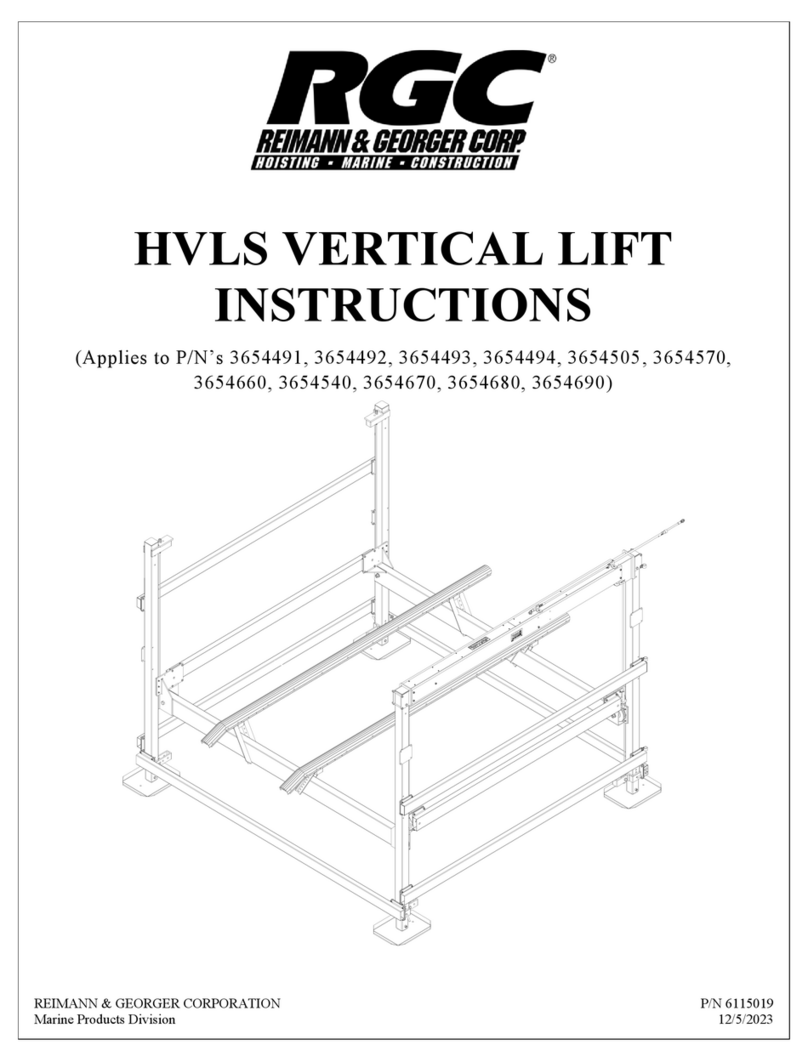

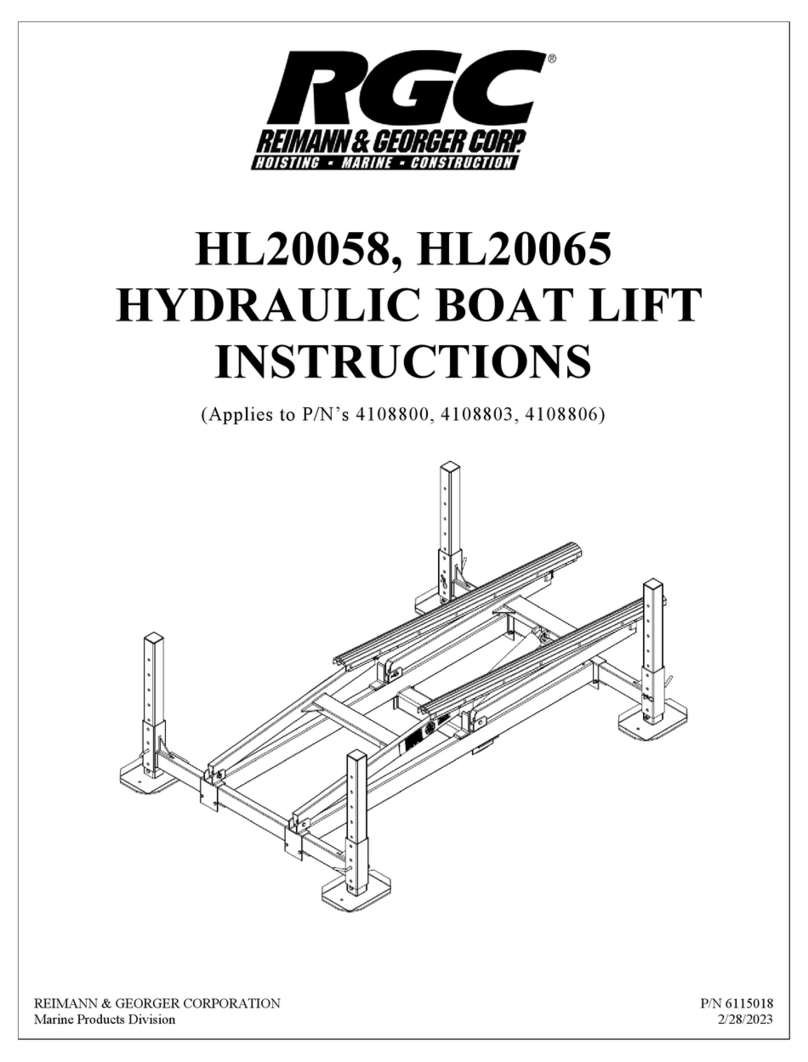

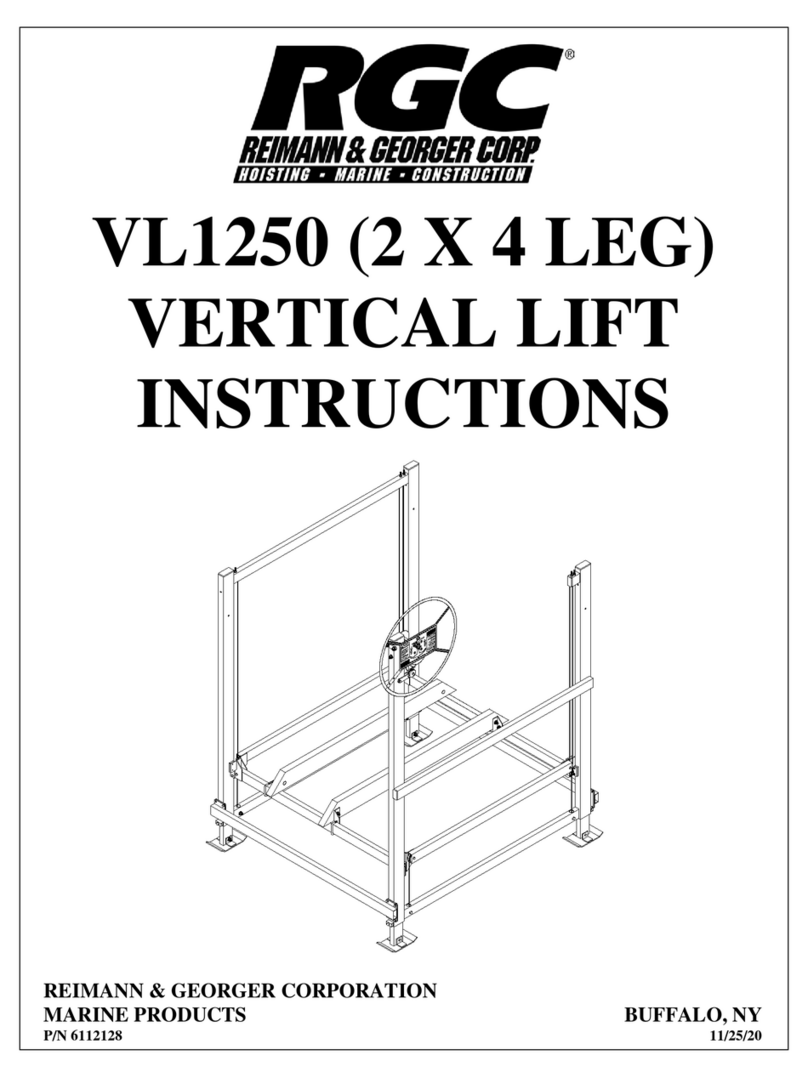

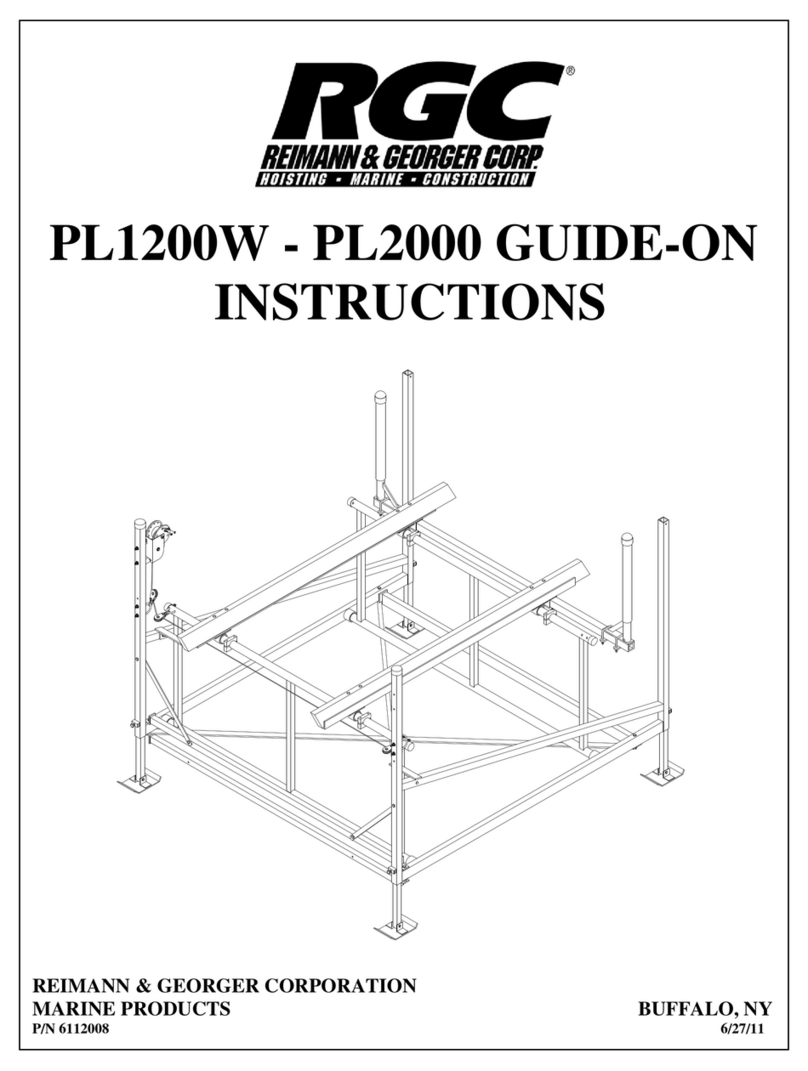

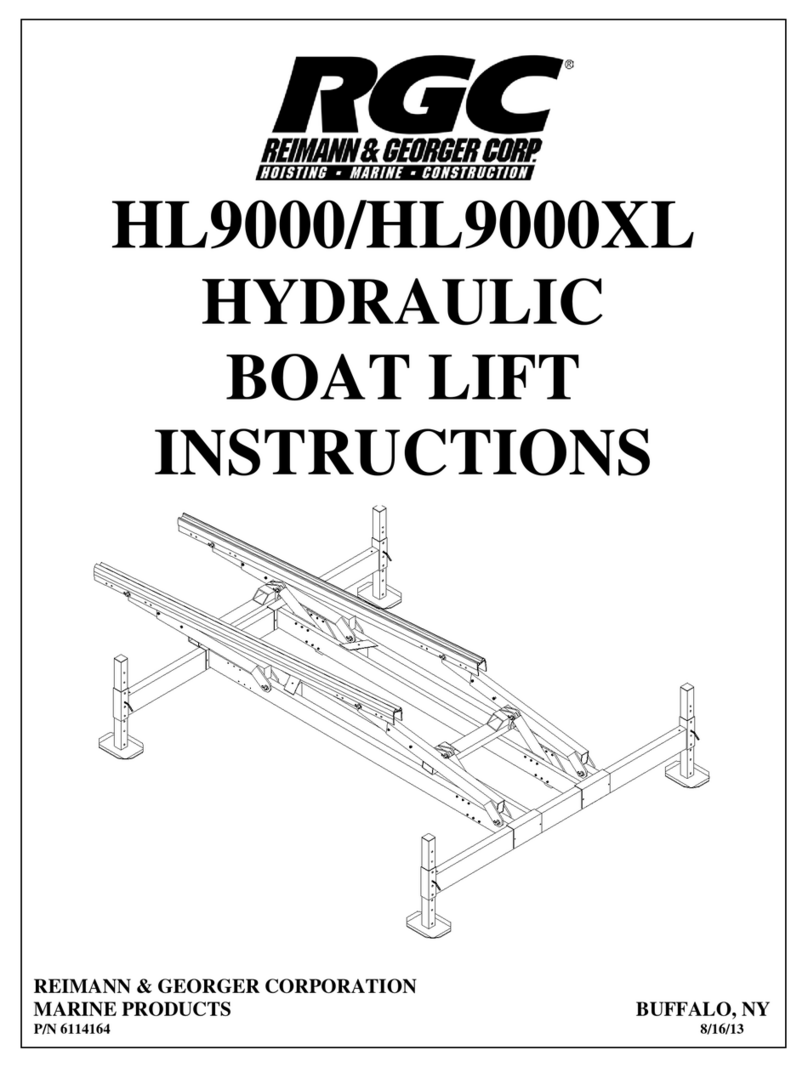

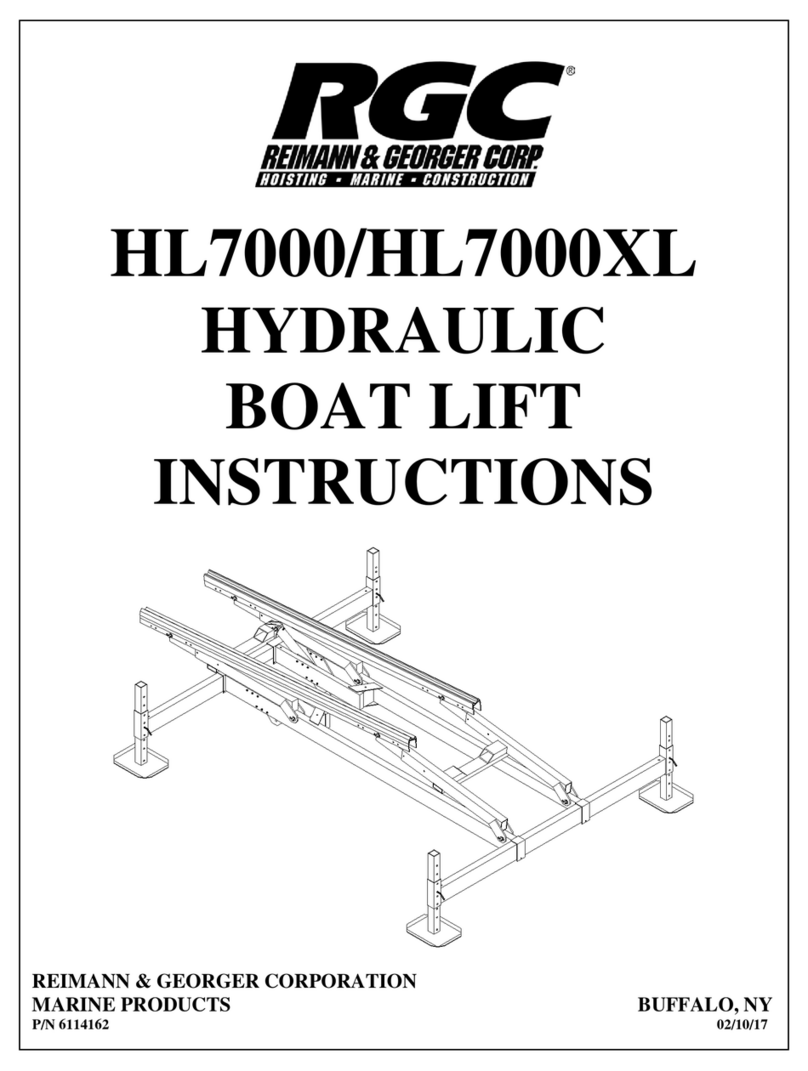

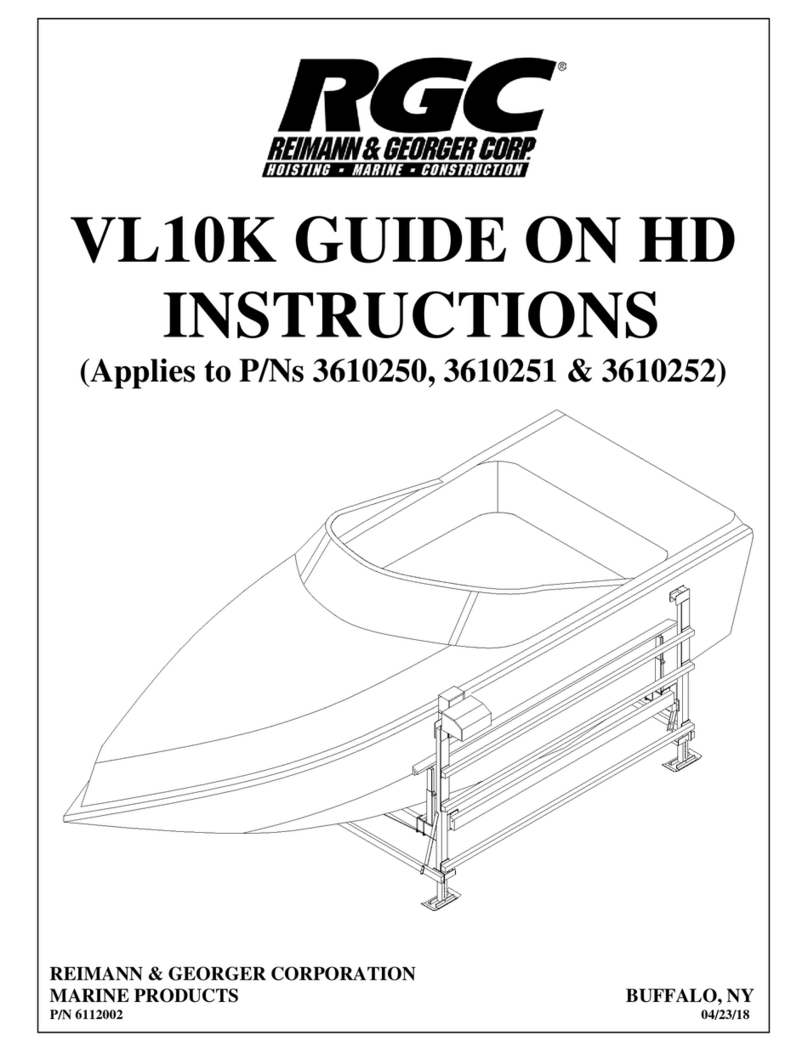

3 INSTALLATION AND SETUP...........................................................................................7

3.1 Pre-Installation Checks............................................................................................................7

3.2 Prior To Setup .........................................................................................................................7

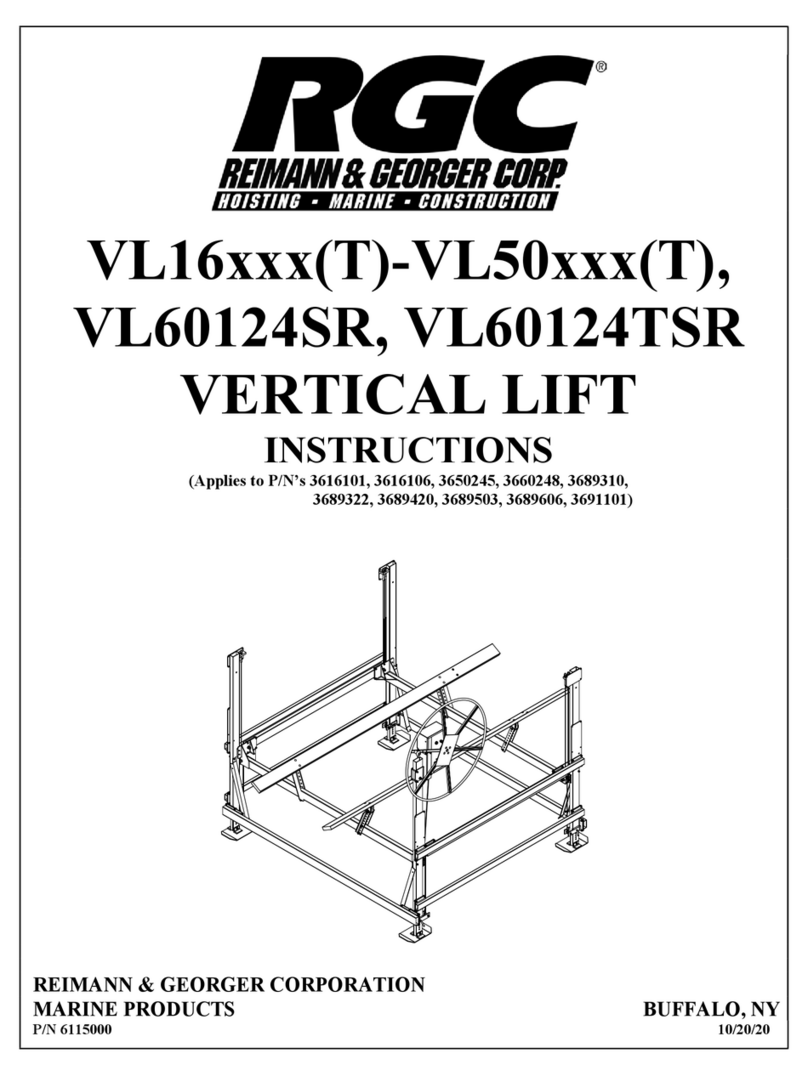

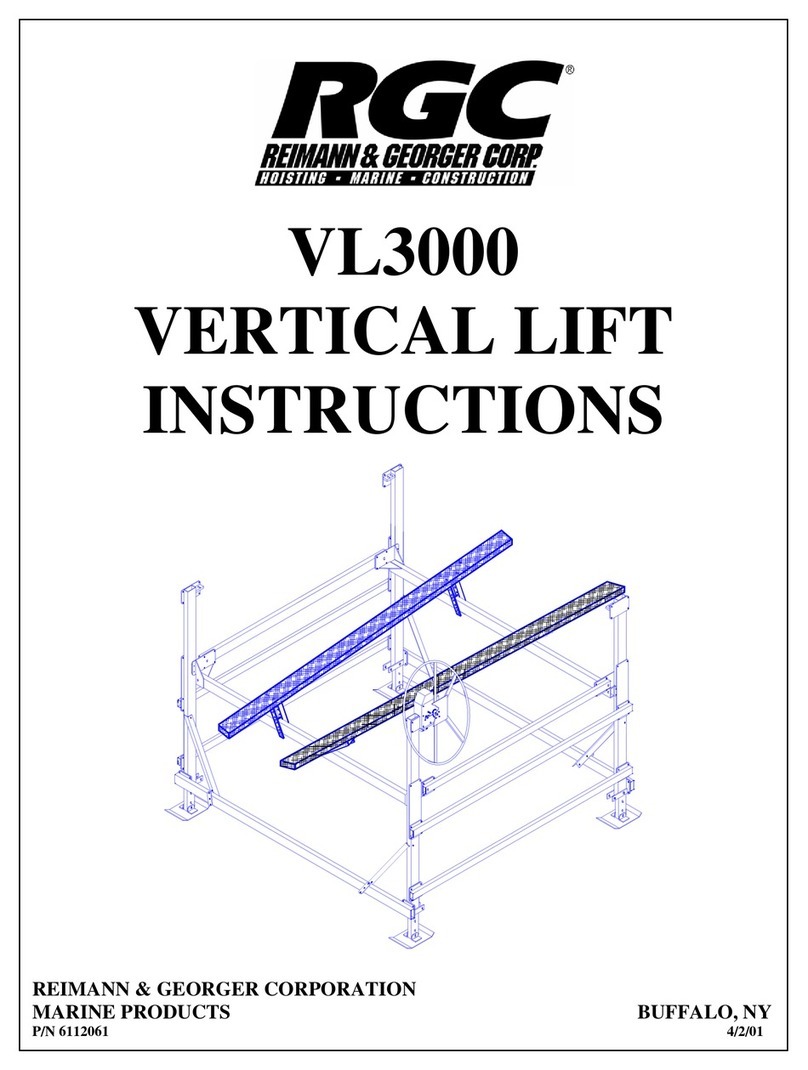

3.3 Vertical Leg Assembly............................................................................................................8

3.4 Frame Side Assembly..............................................................................................................9

3.5 Platform Assembly..................................................................................................................9

3.6 Mounting The Platform To The Frame .................................................................................10

3.7 Mounting The Lower Diagonal Braces.................................................................................11

3.8 Platform Reeving And Adjustment .......................................................................................12

3.9 Winch/Handwheel Mounting ................................................................................................13

3.10 Reeving The Winch...............................................................................................................14

3.11 Moving Lift To Operating Position.......................................................................................15

4 OPERATION.......................................................................................................................16

4.1 Before Operating The Lift.....................................................................................................16

4.2 Testing Winch Operation ......................................................................................................16

4.3 Raising And Lowering The Platform ....................................................................................17

4.4 Securing Lift When Not In Use.............................................................................................17

5 INSPECTION AND MAINTENANCE.............................................................................18

5.1 General Maintenance Rules...................................................................................................18

5.2 Wire Rope Inspection Procedure...........................................................................................18

5.3 Annual Inspection..................................................................................................................19

5.4 Annual Winch Maintenance..................................................................................................19

5.5 Storage Procedure..................................................................................................................20

6 TROUBLESHOOTING......................................................................................................21

7 PARTS LISTS.......................................................................................................................23

7.1 #3616000 VL 16092 Boat Lift Bundles................................................................................23

7.1.1 #3616020 VL 16092 Bundle 1 of 2.......................................................................................23

7.1.2 #3616021 VL 16092 Bundle 2 of 2.......................................................................................23

7.2 VL Extension Legs................................................................................................................23

7.3 #3679355 VL Bunk Carton of Parts......................................................................................23

7.4 #3603778 VL Bunk Bundle ..................................................................................................24