User Manual

UM-OctaneSub4-018-US

Octane Sub4 User Manual |

7

Safety Summary

Safety Summary Continued

• The wheel locks are not intended to brake your

wheelchair. They are only there to ensure that your

wheelchair does not begin rolling unintentionally. When

you stop on uneven ground, you should always use the

wheel locks to prevent such rolling. Always apply both

wheel locks; otherwise, your wheelchair could tip over.

• The wheel locks have not been designed to be used as

brakes for a moving wheelchair.

• Always make use of elevators and ramps. If these are not

available, you should request the help of an attendant.

They should only grip the wheelchair at securely

mounted parts. If anti-tip tubes are tted these must be

folded away. A wheelchair should never be lifted with an

occupant; it should only be pushed.

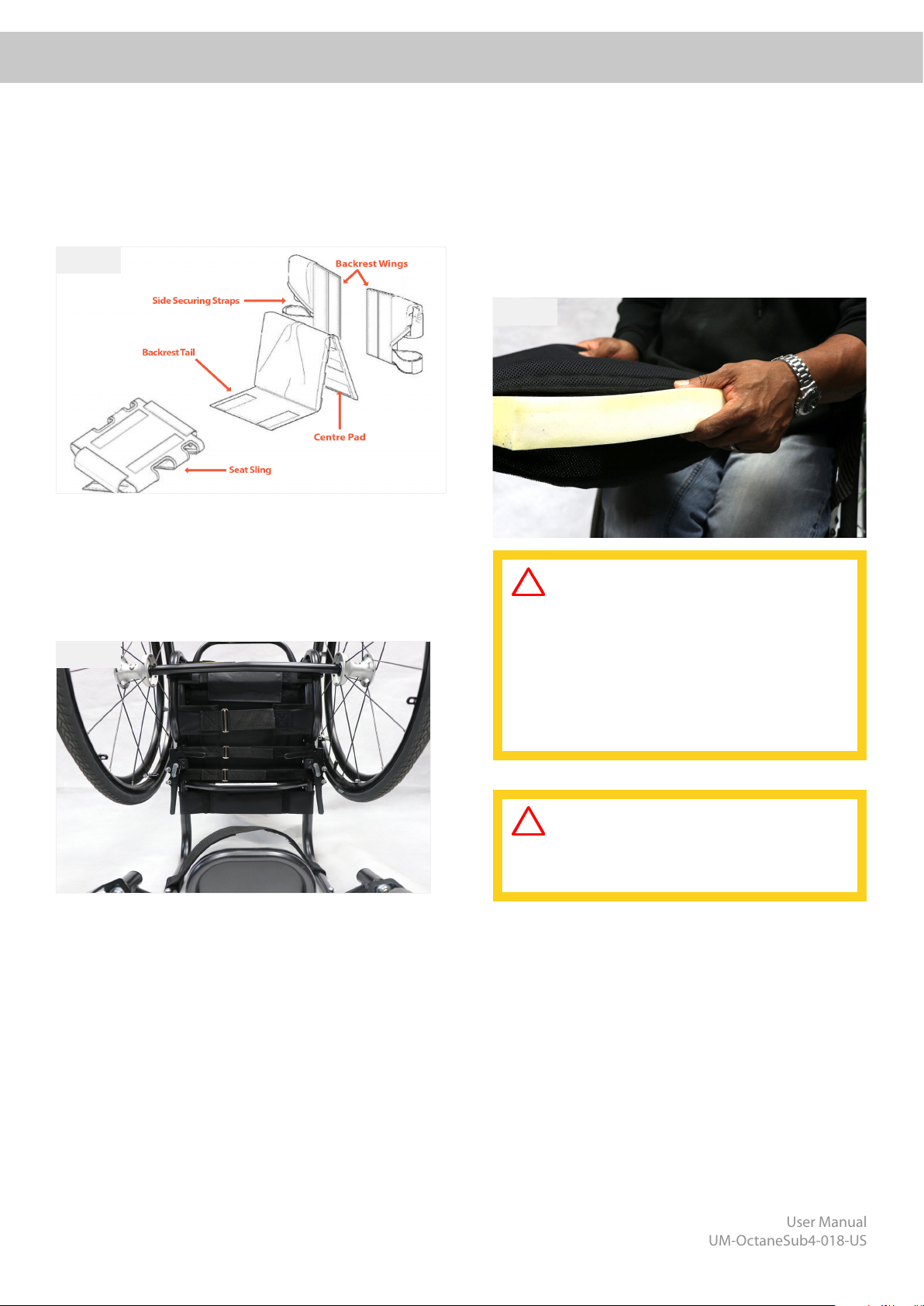

• If the seat and back sling are damaged, you must replace

them immediately.

• Do not lift or carry the wheelchair by the back tubes or

the push handles.

• Be careful with re, in particular with burning cigarettes.

Seat and back slings can be set alight.

• Always make sure that the quick-release axles on the rear

wheels are set properly and are locked in place. If the

button on the quick-release axle is not pressed in, the

rear wheel cannot be removed.

• In particular when using lightweight metal hand rims,

ngers will easily become hot when braking from a high

speed or on long inclines.

• If the wheelchair is subject to direct sunlight for a long

period of time, then parts of the wheelchair (e.g. frame,

leg rests, brakes and side guards) may become hot

(>41°C).

• To avoid hand injuries do not grab in between the spokes

or between the rear wheel and wheel lock when driving

the wheelchair.

• Do not use the wheelchair on slopes > 5°.

• The dynamic safe slope is dependent on the chair

conguration, the user’s abilities and the style of riding.

As the user’s abilities and style of riding cannot be

pre-determined then the max safe slope cannot be

determined. Therefore, this must be determined by

the user with the assistance of an attendant to prevent

tipping. It is strongly recommended that inexperienced

users have anti-tips tted.

• Do not use your wheelchair on muddy or icy ground.

• Do not use your wheelchair where pedestrians are not

allowed.

• The wheelchair should be used with caution in heavy

rain, snow, slippery, or unsound surfaces.

• Do not use the wheelchair in hazardous environments.

• Anti-tip tubes should prevent the chair tipping over

backwards unintentionally. Under no circumstances

should they take the place of transit wheels, and be

used to transport a person in a wheelchair with the rear

wheels removed.

• With extreme settings (e.g. rear wheels in the most

forward position) and less than perfect posture, the

wheelchair may tip over even on a level surface.

• Do not hang heavy items such as shopping bags or

backpacks, on the push handles, head rest or backrest

of the wheelchair. These can change the tipping point

and there is a risk of tipping backwards.

• When reaching for objects which are in front of, to the

side or behind the wheelchair, make sure that you do

not lean too far out of the wheelchair. If you do it can

change the centre of gravity there is a risk of tipping or

rolling over.

• Only use your wheelchair properly. For example, avoid

travelling against an obstacle without braking (step,

kerb edge) or dropping down gaps, or using escalators.

• Only attempt stairs with the help of an attendant. There

is equipment available to help you, e.g. climbing ramps

or lifts, please use them. If there is no such equipment

available, then the wheelchair must be tipped and

pushed over the steps (2 helpers).

• In general, any anti-tip tubes tted must be set

beforehand, so that they cannot touch the steps, as

otherwise this could lead to a serious fall. Afterwards

the anti-tip tubes must be set back to their correct

position.

• Make sure that the attendant only holds the wheelchair

using securely mounted parts (e.g. not on the footrests

or the side guards).

• When using the lifting ramp make sure that the anti-tip

tubes tted are positioned outside the danger area.

• Secure your wheelchair on uneven ground or when

transferring (e.g. into a car) by using the wheel locks.

• The wheel locks will only work if there is sucient tyre

pressure and if the correct setting has been made (see

the Chapter on“Wheel locks”).

• When it is dark, please wear light clothing or clothing

with reectors, so that you can be seen more easily.

Make sure that the reectors on the side and back

of the wheelchair are clearly visible. We would also

recommend that you t an active light.

• Adjustments to your wheelchair, especially to security-

relevant components as for example wheel-locks,

anti-tip or backrest must be performed by authorized

dealers.

• It is recommended to clean and disinfect the entire

product, especially the upholstery, frequently.

• Do not tilt the wheelchair without assistance

• Do not reuse single use fasteners