6

Note the following recommendations:

• Crockery and cutlery should not be inserted inside one another, covering each other.

• Place the crockery in order to all surfaces can be reached by water; otherwise the dishes

are not washed.

• Make sure all the crockery are in a stable position and that the hollow containers don't

overturn (cups, glasses, bowls, etc.) .

• Place in the rack all the hollow containers such as cups, glass, etc. upside-down.

• Place the crockery with deep hollow with upper face downwards, so that water can flow

out.

• Make sure the smaller crockery do not fall from the rack.

• Check all the wash arms runs freely and they are not blocked by too tall or too prominent

crockery. Eventually, run a manual rotation of the arms to check it.

Some foods, such as carrots, tomatoes, and others, may contain some natural dyes sub-

stances, that in large amounts, can alter the crockery and plastic parts colors.

Any discoloration does not mean that the plastic is not heat resistant.

Crockery and cutlery not suitable for dishwasher

Not suitable for dishwasher:

• Wooden crockery and cutlery or with wooden parts; water at high temperature causes

deformation to wood. Also the adhesives used are not suitable for treatment in the

dishwasher; a consequence could be the handles detachment.

• Crafts, precious vases or decorated glasses.

• Not heat-resistant plastic crockery.

• Copper, brass, pewter or aluminum objects: they may become discolored or opaque.

• The decorations on glass, after a certain number of washes, can lose gloss.

• Fragile glasses or crystal items, if often washed, can become opaque.

We recommend to buy exclusively crockery and cutlery suitable for dishwashing.

After several washes, the glass can become opaque.

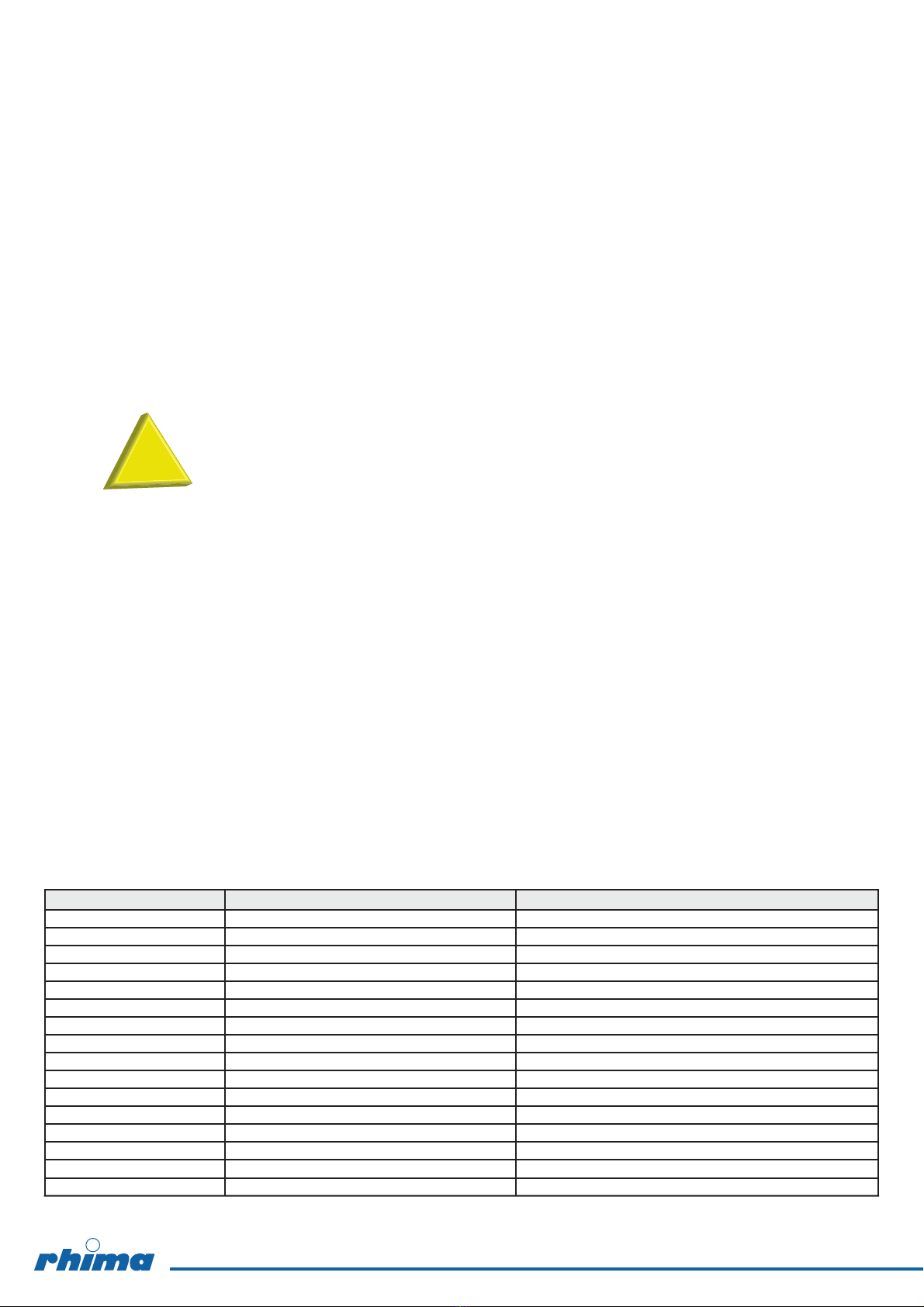

It is mandatory to repeat the washing cycle if at the end of the cycle the crockery

are not well clean or if there are washing residues (glasses, cups, bowls, etc. with

liquid inside).

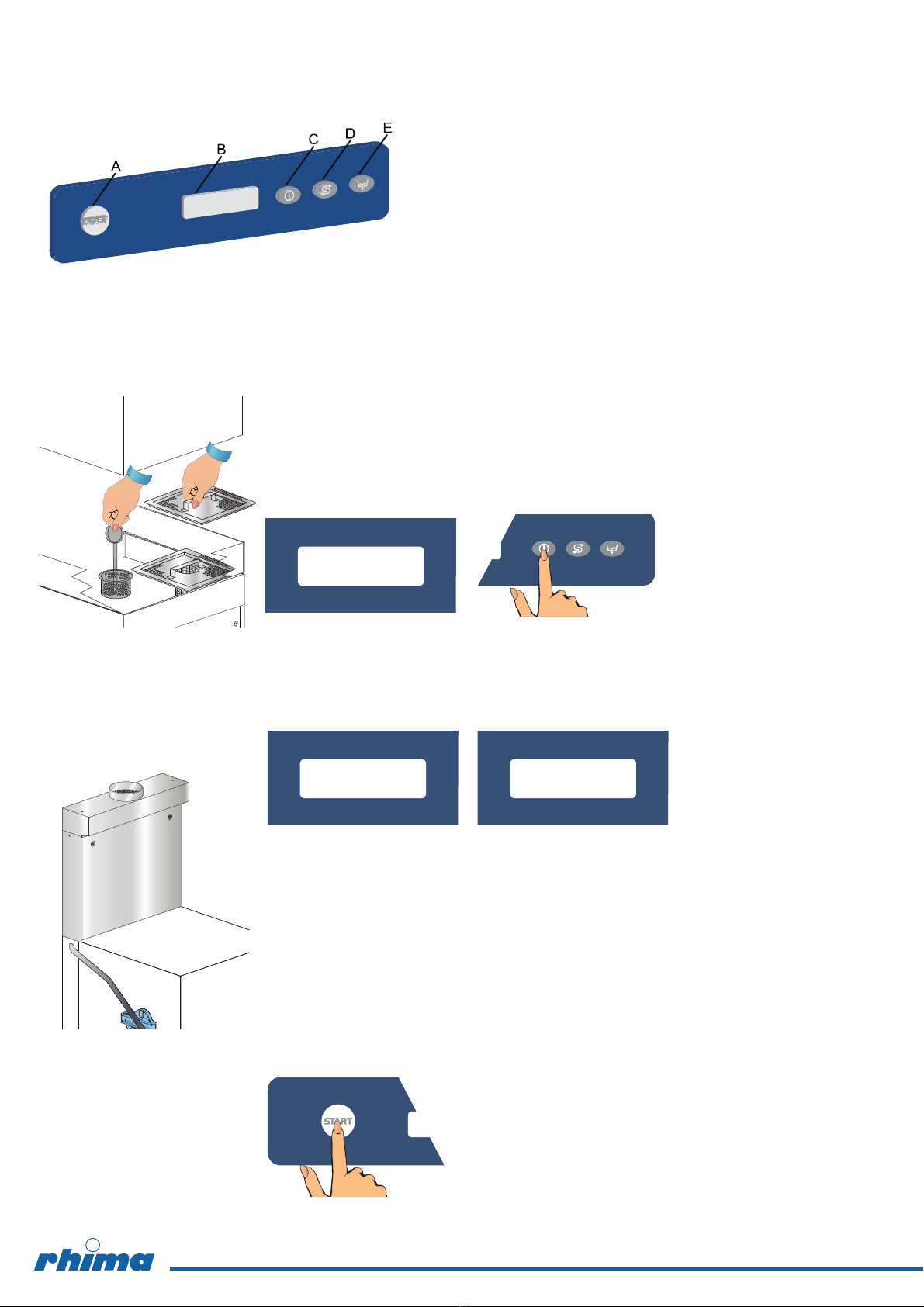

Detergent use

The machine has a standard detergent dispenser. The machine automatically sucks the

product.

The detergent shall be the NO FOAM type, suitable for industrial dishwashers.

The detergent must be introduced in the tank. The use of good quality liquid detergents

is recommended. By request the dishwasher can be equipped with an electric detergent

dispenser (always recommended).

Follow the manufacturer’s recommendations for chemical dosage, related to the local water

hardness. 1cm. of the product drawn into the tube is equal to about 0.15 g. A correct amount

of detergent is very important for a successful wash.

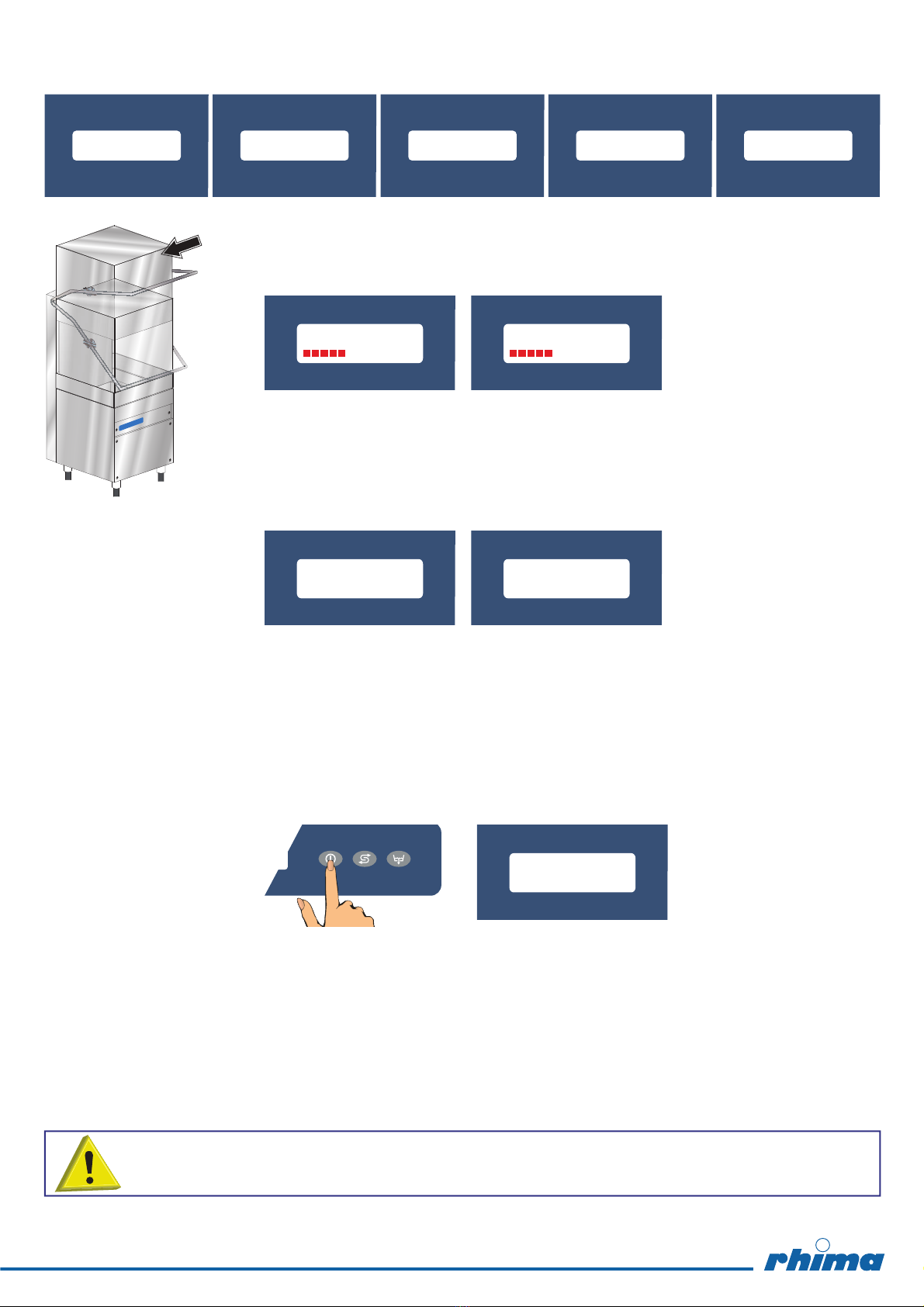

Should the detergent lack, the display will show DETERGENT LEVEL (only with optional

"Sensor for Chemicals Low Level").

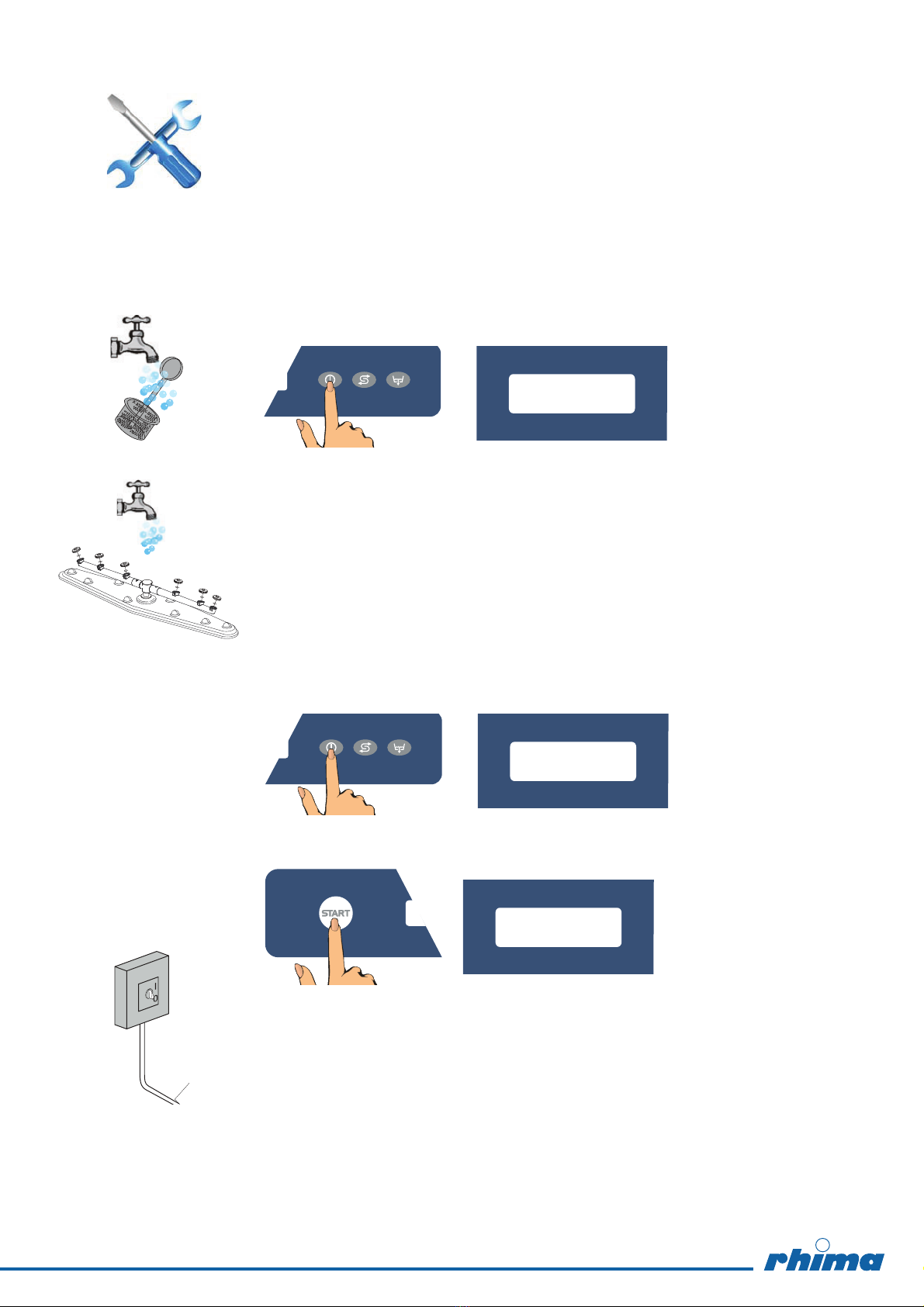

DETERGENT

DETERGENT LEVEL

Pict. 4

Pict. 5