This machine is built with high quality materials in particular AISI 304 stainless steel (AISI 316 for boilers and tanks) and in

high thickness to ensure a longer lifetime.

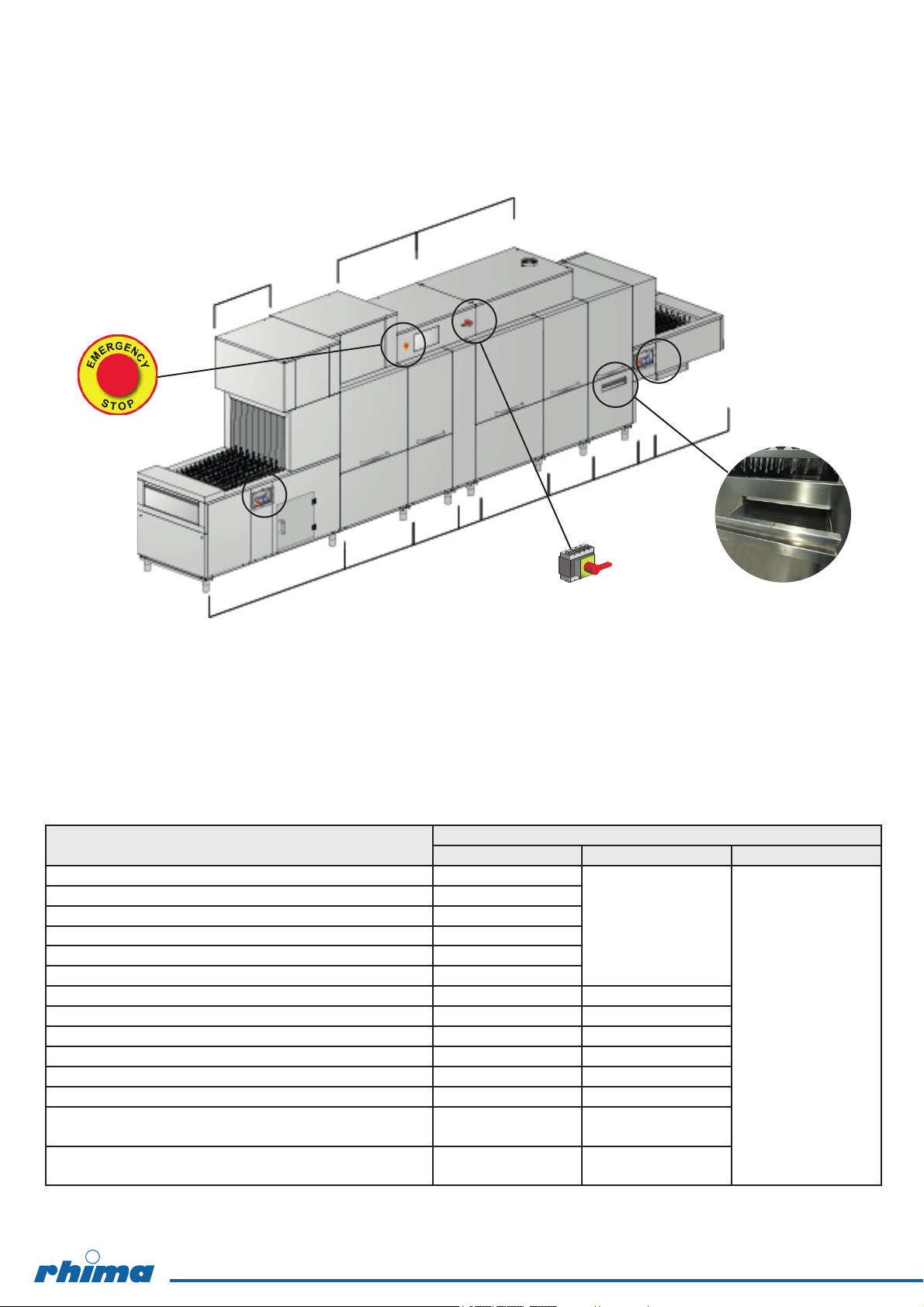

The machine is built in di erent sections:

Pre-wash module C (the presence depends on the model chosen): a preliminary rough washing is carried out with low

temperature thermostatically controlled to melt the alimentary residuals and avoid the proteins denaturation.

On machines with pre-wash, the initial tanks filling occurs in several phases:

- Phase 1: wash tanks only filling

- Phase 2: filling interruption. Water heating using the heating elements until a proper pre-wash temperature is reached

(factory-set)

- Phase 3: resume and filling conclusion.

- Phase 4: resume and heating conclusion.

Wash module(s) D: a proper washing of the crockery is performed with temperature thermostatically controlled.

Rinse module F: a pre-rinse is performed that removes most of the detergent, then a final rinse is performed with high

temperature thermostatically controlled.

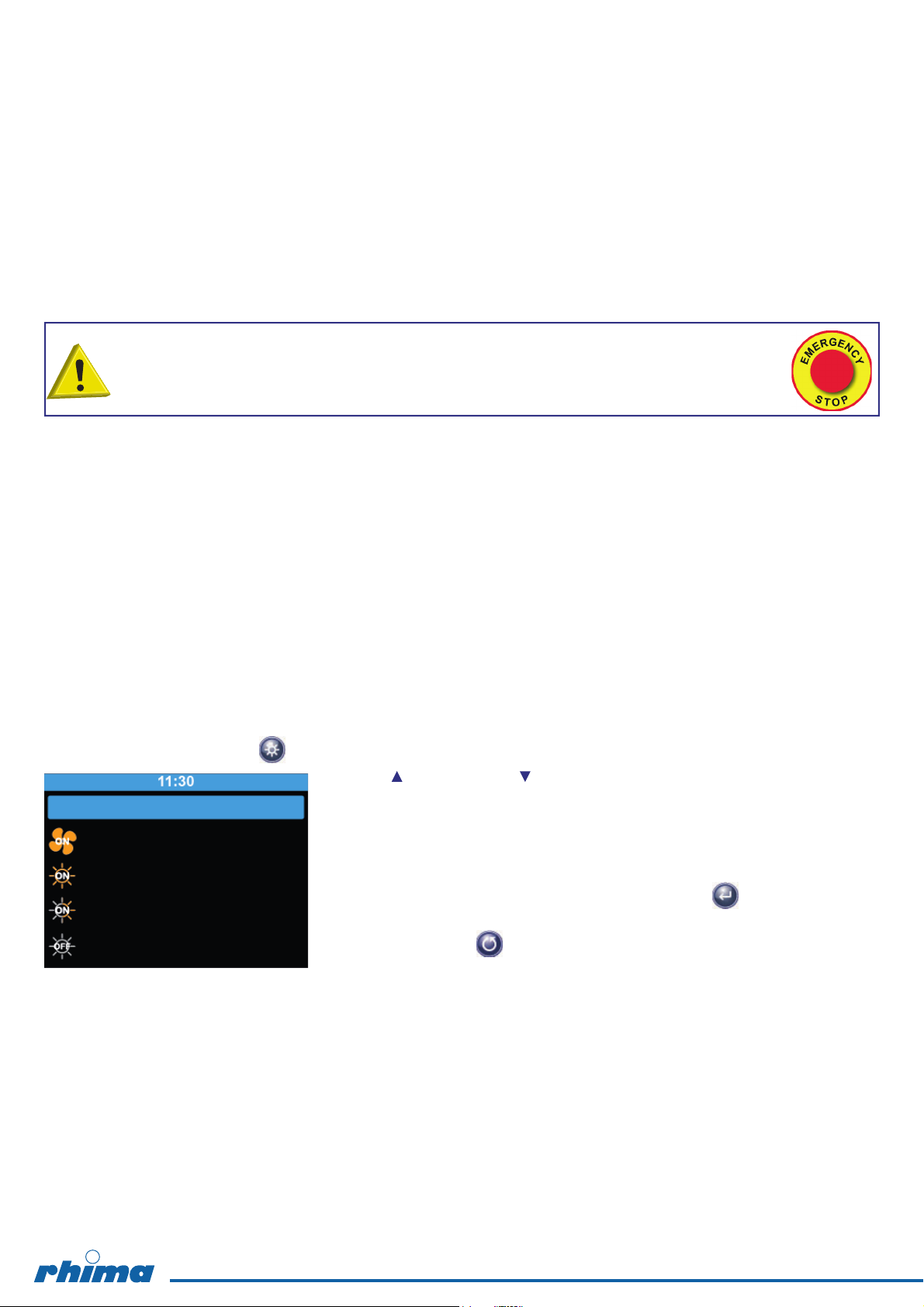

Autotimer: the Autotimer function (activated by default) allows stopping the machine if it is in start-mode but not operating

at the moment.

It can happen in these cases:

1. The machine is working in vain (it is in operation but it is not used).

2. The machine is in operation but an objects accumulation exiting the machine causes the limit switch SQ1 to trip (F1).

3. The machine is in operation with the drawer Mopen.

In these cases, the timer set by default at 300 seconds trips. When the time is over the energetic saving mode turns on.

By inserting some objects, clearing the exit or closing the drawer the machine restarts automatically to operate.

Automatic drain:

Each tank is provided with dedicated motorized valve. The end work draining occurs when the machine is in stand-by by

pressing the dedicated key and without having to open the doors and getting in touch with the washing solution.

If there is the Pre-wash module or the Automatic shower with drawer strainer optional, it is possible to drain only the pre-

wash tanks and then to ensure the pre-wash tanks regeneration (where most of the residuals accumulate) and to keep an

ecient and low consumption washing.

Available options

Automatic shower with drawer strainer B:

Module with low temperature water thermostatically not controlled, with drawer strainer M.

The filter collects the food residuals and it can easily be removed and cleaned during the operation thanks to the drawer,

without opening the doors and getting in touch with the washing solution.

If the drawer is extracted during the washing, the machine stops the conveyor, the rinse and the module pump to allow the

filter cleaning.

The wash pumps keep working.

The machine restart the operation as the drawer is repositioned.

Make sure that during the operation the filter is clean and correctly positioned.

Dryer G:

It conveys hot and dry air that creates the ideal conditions for the rinse aid action.

Depending on his/her needs the operator can turn on or off the dryer module heating power, during the work.

Based upon needs, it is possible to set maximum power, or partial power, or fan only, or turn the dryer completely off.

Heat recovery L:

The goal is the recovery of the steam heat exiting the machine that otherwise would be dispersed, and use it to pre-heat

the water entering the boiler.

The machine must have a cold water supply for the rinse.

5