RHINO METALS Longhorn LSB1014 User manual

Other RHINO METALS Safe manuals

Popular Safe manuals by other brands

Euromate

Euromate 406210 Original instructions

SPORTS AFIELD

SPORTS AFIELD PRESERVE SA72-60WD instruction manual

Squire

Squire Stronghold Keysafe Fitting instructions

Phoenix

Phoenix FS0352C Instructions & Guarantee Registration

Hornady

Hornady SnapSafe Trunk Safe II owner's manual

Phoenix

Phoenix KS0030E Series operating instructions

Vaultek

Vaultek 10 Series Quick setup

Arregui

Arregui CLASS operating instructions

Technomax

Technomax Trony Series Instruction handbook

SPORTS AFIELD

SPORTS AFIELD INSTINCT BIOMETRIC Series instruction manual

SPORTS AFIELD

SPORTS AFIELD SA-HD5-BIO instruction manual

Olymp

Olymp GOsafe 110 operating instructions

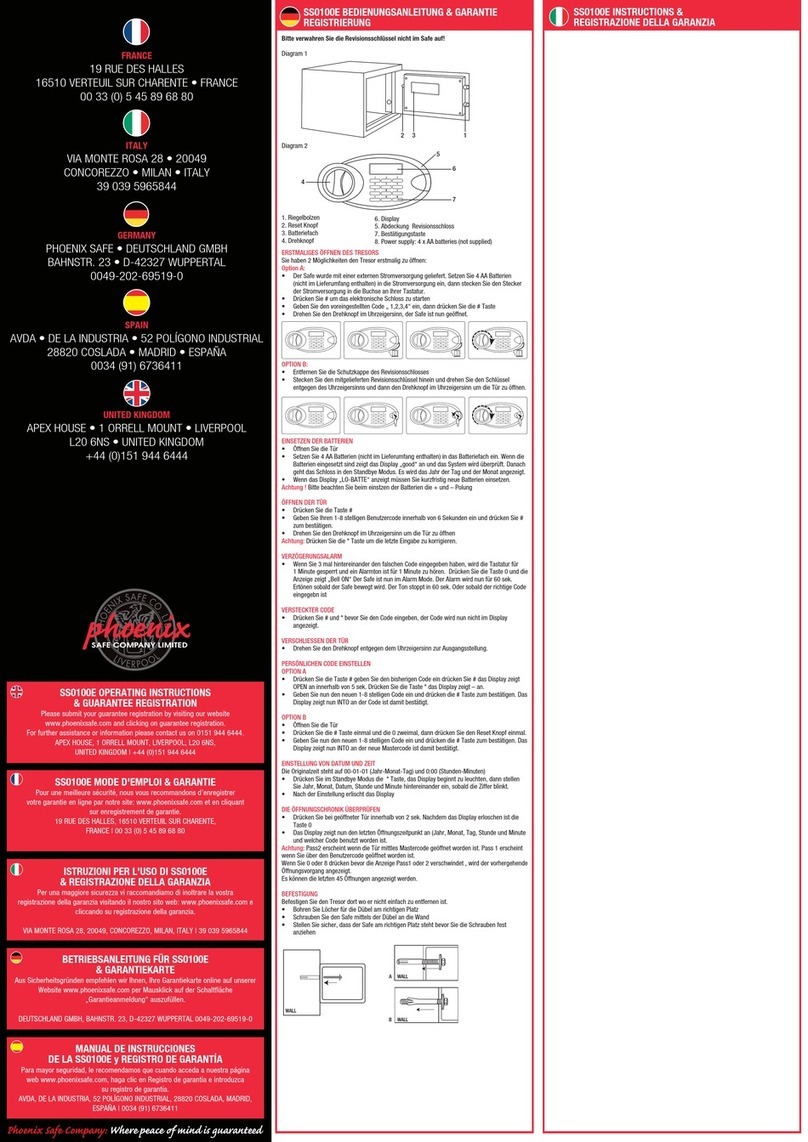

Phoenix

Phoenix SS0100E Operating Instructions & Guarantee Registration

Ankaro

Ankaro ANK EZ I quick start guide

Honeywell

Honeywell 2077D - 1.21 Cubic Foot Anti-Theft Safe user guide

Beaumont

Beaumont SMART KEYBOX user guide

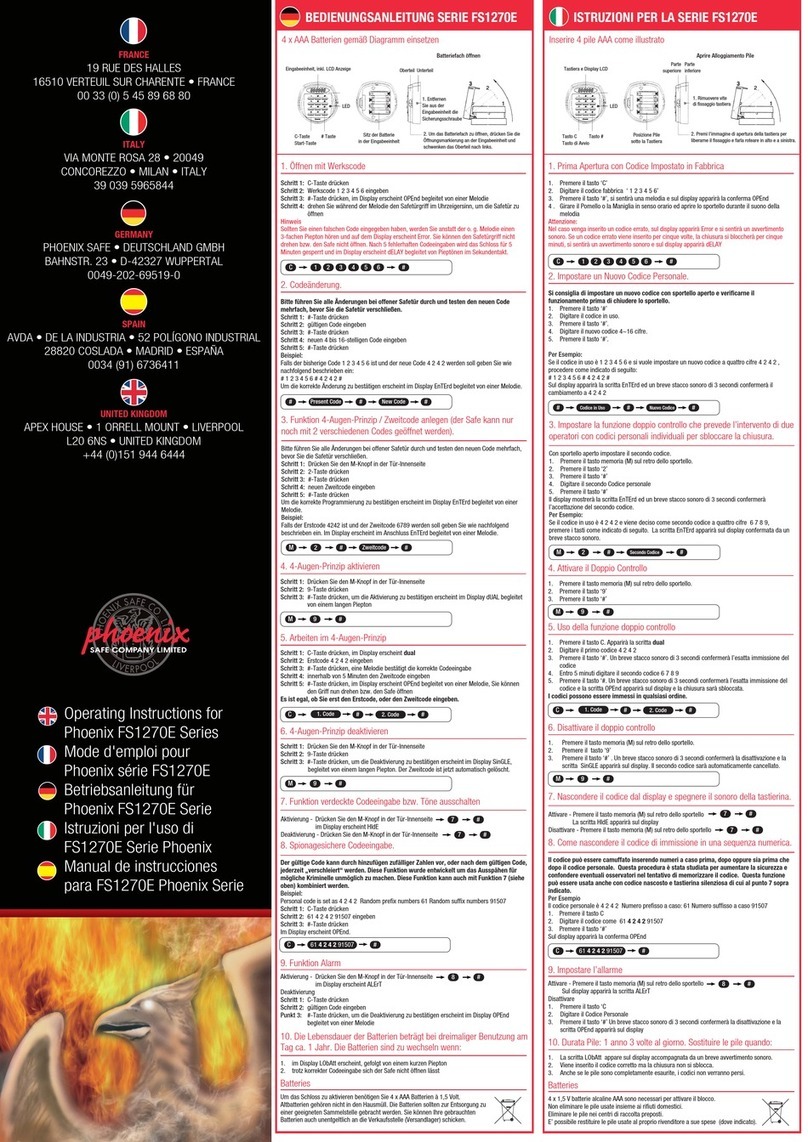

Phoenix

Phoenix FS1270E Series operating instructions

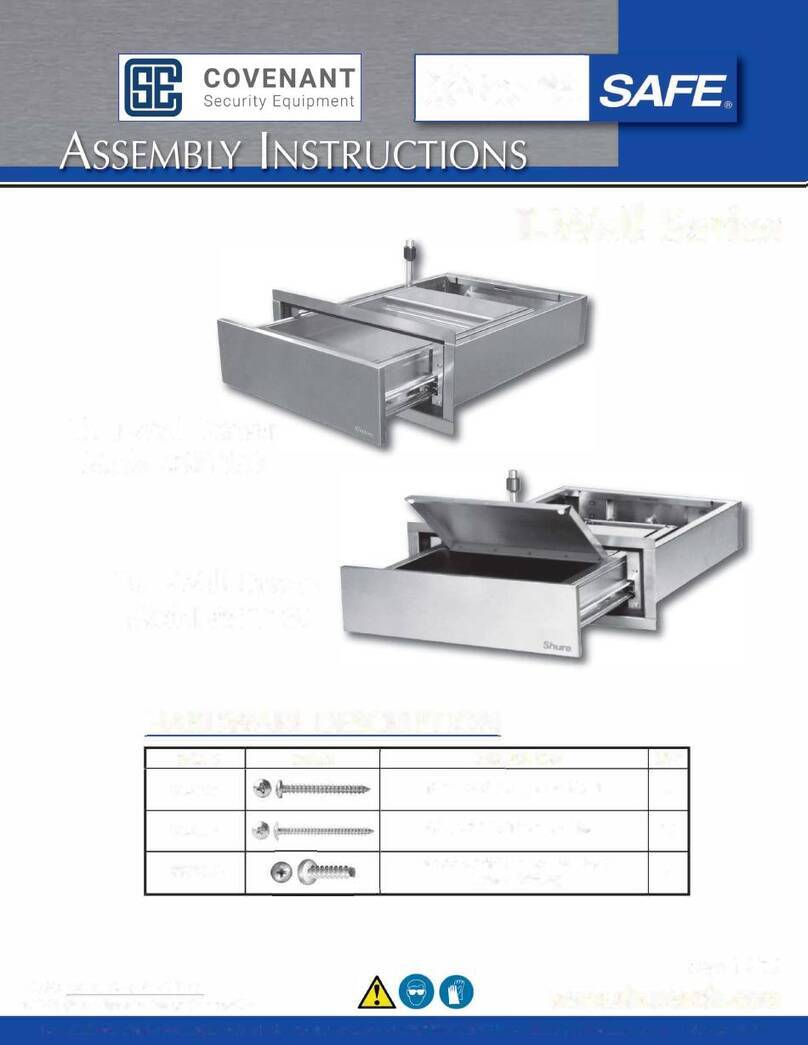

Shure

Shure T-Wall Series Assembly instructions