i

i

Your safety, and the safety of others, is very important. The

proper and safe use of your Rhino® post driver is an important

responsibility and should be taken

seriously.

This entire book is lled with

important safety information. Please

read it carefully.

Keep this owner’s manual handy, so you

can refer to it at any time. This owner’s

manual is considered a permanent part of

the post driver and should remain with the

post driver if resold.

The information and specications includ-

ed in this publication were in effect at the

time of approval for printing. Rhino Tool

Company, Inc. reserves the right, however,

to discontinue or change specications or

design at any time without notice and with-

out incurring any obligation whatever. No

part of this publication may be reproduced

without written permission from Rhino

Tool Company.

To help you make informed decisions about safety, you will nd

important safety information in a variety of forms, including:

• Safety Labels on the post driver

• Safety Messages Preceded by a safety alert symbol and one of

three signal words, DANGER, WARNING, or CAUTION.

These signal words mean:

!DANGER

Immediate hazards that will result in

severe personal injury or death.

!WARNING

!DANGER

!CAUTION

IMPORTANT

NOTE

Hazards or unsafe practices that could

result in personal injury.

!

Hazards or unsafe practices that could result in injury,

product or property damage.

• Safety Headings such as IMPORTANT SAFETY

INFORMATION.

• Safety Section such as POST DRIVER SAFETY.

• Instructions how to use this post driver correctly and safely.

Your safety, and the safety of others, is very important. The

proper and safe use of your Rhino® post driver is an important

responsibility and should be taken

seriously.

This entire book is lled with

important safety information. Please

read it carefully.

Keep this owner’s manual handy, so you

can refer to it at any time. This owner’s

manual is considered a permanent part of

the post driver and should remain with the

post driver if resold.

The information and specications includ-

ed in this publication were in effect at the

time of approval for printing. Rhino Tool

Company, Inc. reserves the right, however,

to discontinue or change specications or

design at any time without notice and with-

out incurring any obligation whatever. No

part of this publication may be reproduced

without written permission from Rhino

Tool Company.

To help you make informed decisions about safety, you will nd

important safety information in a variety of forms, including:

• Safety Labels on the post driver

• Safety Messages Preceded by a safety alert symbol and one of

three signal words, DANGER, WARNING, or CAUTION.

These signal words mean:

!DANGER

Immediate hazards that will result in

severe personal injury or death.

!WARNING

!DANGER

!CAUTION

IMPORTANT

NOTE

Hazards or unsafe practices that could

result in personal injury.

!

Hazards or unsafe practices that could result in injury,

product or property damage.

• Safety Headings such as IMPORTANT SAFETY

INFORMATION.

• Safety Section such as POST DRIVER SAFETY.

• Instructions how to use this post driver correctly and safely.

TAKE SAFETY SERIOUSLY

TAKE SAFETY SERIOUSLY

GPD-40 Fence Pro™Trouble Shooting

GPD-40 Fence Pro™Trouble Shooting

21

21

Post lodged in driver with adapter installed: Turn off the engine. Remove the Chuck-Lok™System’s locking nut from the master chuck and slide

down the post. Using the handles, lift postdriver upward, allowing the post adapter to slide out. If the pressure from the ared post does not allow you

to lift driver off the post, locate the pry gaps on the adapter base and use a athead screwdriver to pry them downward. Be careful not to damage the

master chuck threads. Once loosened, lift using the postdriver handles. As the two-piece adapter frees from the chuck tube they separate from the post.

Slide the locking nut off the post, reinsert the adapter, apply the locking nut and resume post driving.

Post lodged in master chuck: Remove the four 5/16” lower body bolts and separate the lower body casting from the driver body. Slide the lower body

casting down the post to expose the ared top of the post. With the proper cutting tool for the type of post, cut through the post below the ared portion.

Once the ared portion is removed, slide the lower body casting off the post and reassemble it to the driver. Please follow bolt tightening procedure and

use thread locker solution.

Recommendation: Do not use “thin-wall” or light gauge round post with the GPD-40 Ranch Pro™. It is very likely to flare this type of post at full throttle.

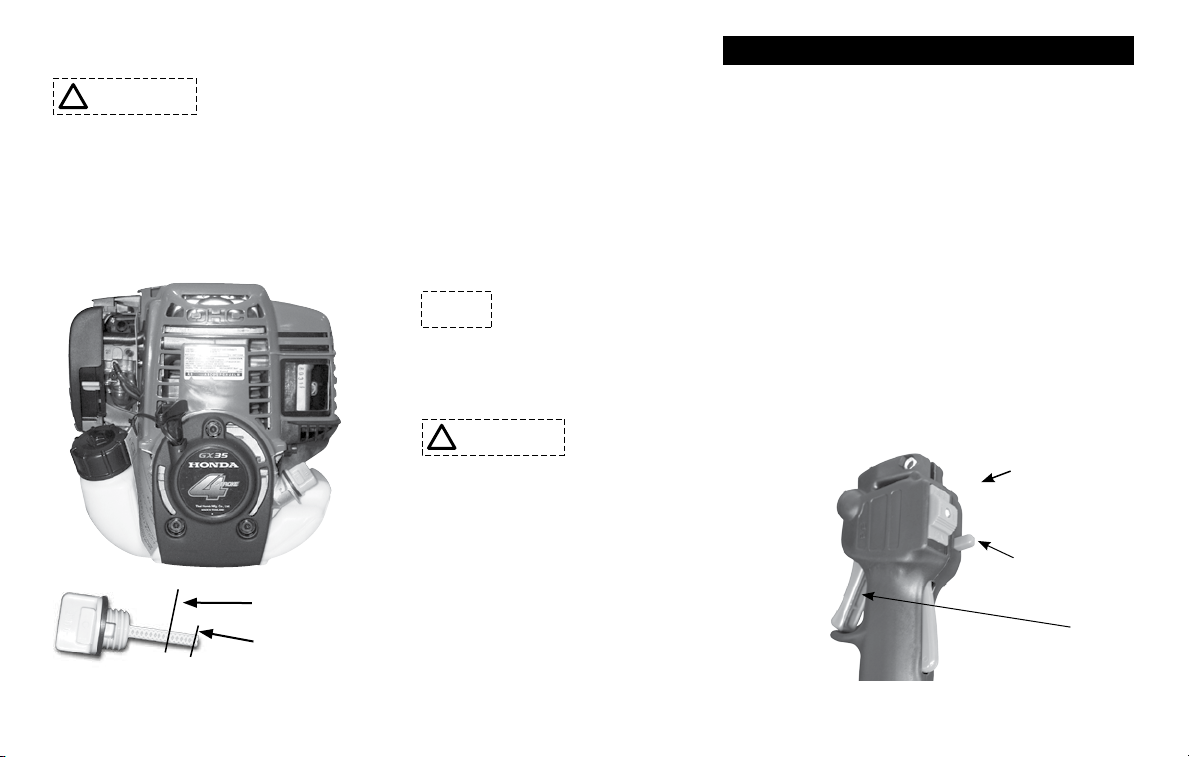

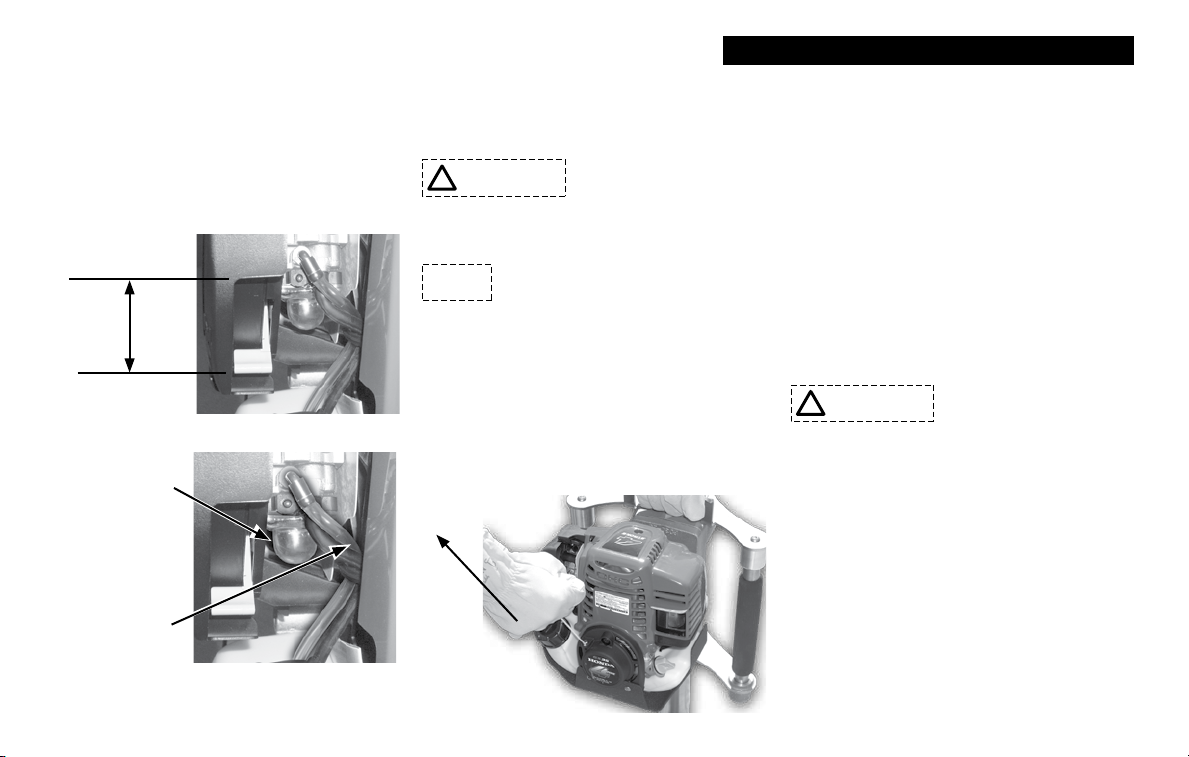

Drives post slow or sluggish engine performance: Typically this is resulting from improper driver storage or over-lling the oil causing the oil to

seep into the combustion chamber. Turn off the engine. Position the driver vertically, remove the dipstick to check oil level. (See page 6) If you need to

remove some oil, dispose of it properly. If oil is at proper level, follow the procedure listed in “Pull-start is frozen or hard to pull.” It also is good practice

to wipe clean the engine after use.

Pull-start is frozen or hard to pull: This typically results from oil seeping into the combustion chamber from improper driver storage or overlling the

oil reservoir of the engine. Remove spark plug and pull hand grip a several times until it pulls freely. Replace the spark plug. Check the oil level in oil

reservoir to ensure proper level (page 6). Follow starting procedure. It is not unusual, for blue smoke to be emitted from the engine, let the engine run

until smoke clears.

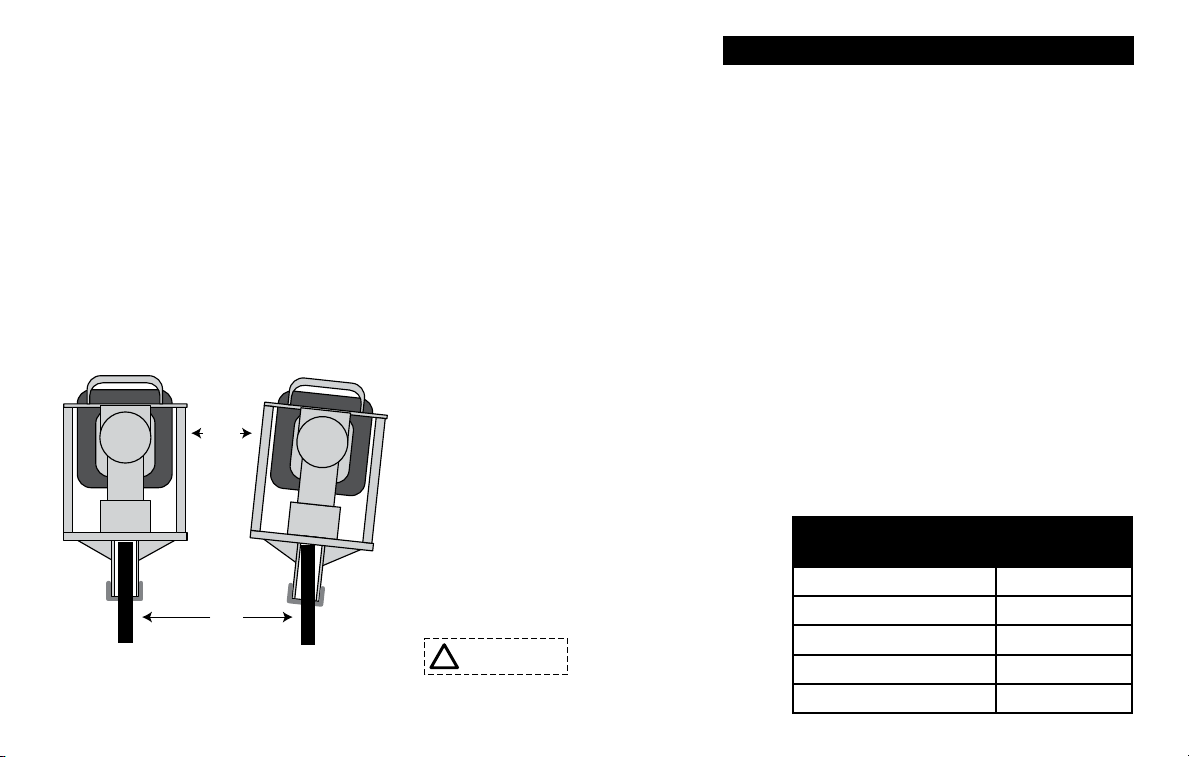

Proper Storage: When storing your GPD-40, do not lay it horizontally on the driver side or resting on the engine. If the unit cannot be stored securely in

the upright position, place the chuck on the at surface, lean it toward the engine side until it is supported by the shroud and chuck. This will position the

driver on an angle with the top handle at the topmost point.

Other problems or technical questions: Have your serial number handy and contact Rhino Tool Company. Phone: 309.853.5555 or Toll Free 866-

Post lodged in driver with adapter installed: Turn off the engine. Remove the Chuck-Lok™System’s locking nut from the master chuck and slide

down the post. Using the handles, lift postdriver upward, allowing the post adapter to slide out. If the pressure from the ared post does not allow you

to lift driver off the post, locate the pry gaps on the adapter base and use a athead screwdriver to pry them downward. Be careful not to damage the

master chuck threads. Once loosened, lift using the postdriver handles. As the two-piece adapter frees from the chuck tube they separate from the post.

Slide the locking nut off the post, reinsert the adapter, apply the locking nut and resume post driving.

Post lodged in master chuck: Remove the four 5/16” lower body bolts and separate the lower body casting from the driver body. Slide the lower body

casting down the post to expose the ared top of the post. With the proper cutting tool for the type of post, cut through the post below the ared portion.

Once the ared portion is removed, slide the lower body casting off the post and reassemble it to the driver. Please follow bolt tightening procedure and

use thread locker solution.

Recommendation: Do not use “thin-wall” or light gauge round post with the GPD-40 Ranch Pro™. It is very likely to flare this type of post at full throttle.

Drives post slow or sluggish engine performance: Typically this is resulting from improper driver storage or over-lling the oil causing the oil to

seep into the combustion chamber. Turn off the engine. Position the driver vertically, remove the dipstick to check oil level. (See page 6) If you need to

remove some oil, dispose of it properly. If oil is at proper level, follow the procedure listed in “Pull-start is frozen or hard to pull.” It also is good practice

to wipe clean the engine after use.

Pull-start is frozen or hard to pull: This typically results from oil seeping into the combustion chamber from improper driver storage or overlling the

oil reservoir of the engine. Remove spark plug and pull hand grip a several times until it pulls freely. Replace the spark plug. Check the oil level in oil

reservoir to ensure proper level (page 6). Follow starting procedure. It is not unusual, for blue smoke to be emitted from the engine, let the engine run

until smoke clears.

Proper Storage: When storing your GPD-40, do not lay it horizontally on the driver side or resting on the engine. If the unit cannot be stored securely in

the upright position, place the chuck on the at surface, lean it toward the engine side until it is supported by the shroud and chuck. This will position the

driver on an angle with the top handle at the topmost point.

Other problems or technical questions: Have your serial number handy and contact Rhino Tool Company. Phone: 309.853.5555 or Toll Free 866-