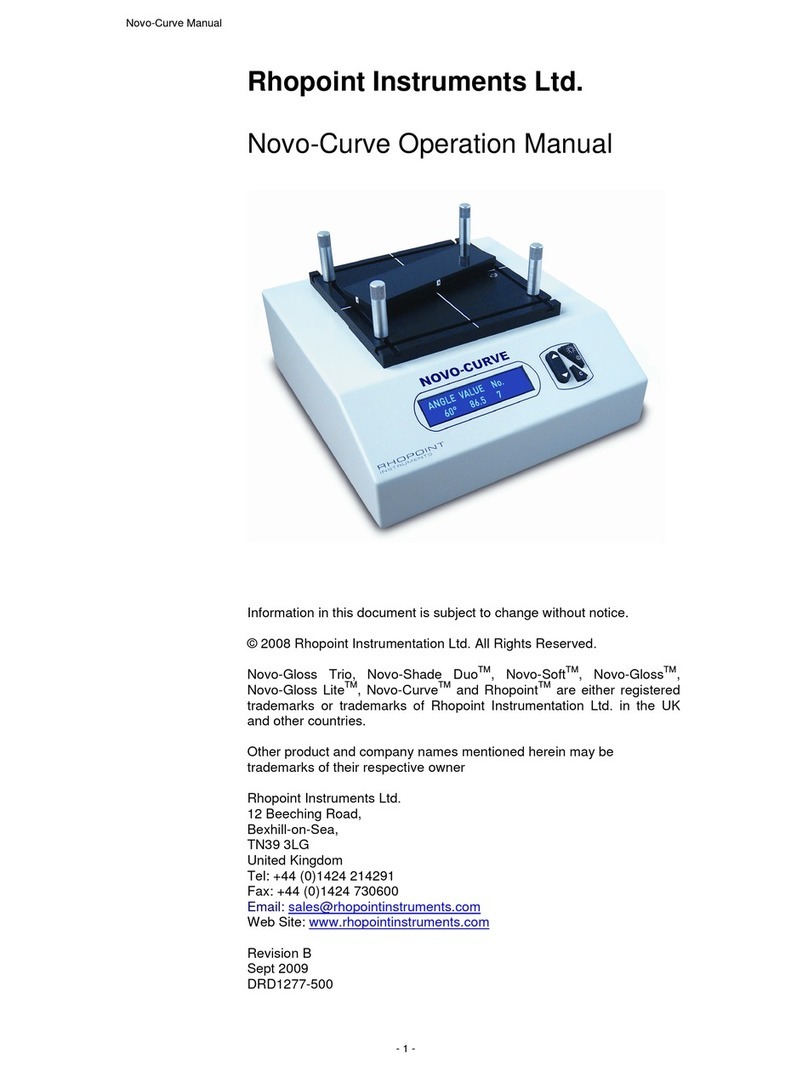

Rhopoint Instruments Novo-Curve 4 User manual

Other Rhopoint Instruments Measuring Instrument manuals

Rhopoint Instruments

Rhopoint Instruments Novo-Curve Installation manual

Rhopoint Instruments

Rhopoint Instruments NOVO-GLOSS 60 User manual

Rhopoint Instruments

Rhopoint Instruments NG Flex 60 User manual

Rhopoint Instruments

Rhopoint Instruments IQ Flex 20 User manual

Rhopoint Instruments

Rhopoint Instruments MFFT-90 User manual

Rhopoint Instruments

Rhopoint Instruments Optimap PSD 3 User manual

Rhopoint Instruments

Rhopoint Instruments IDTX User manual

Popular Measuring Instrument manuals by other brands

Powerfix Profi

Powerfix Profi 278296 Operation and safety notes

Test Equipment Depot

Test Equipment Depot GVT-427B user manual

Fieldpiece

Fieldpiece ACH Operator's manual

FLYSURFER

FLYSURFER VIRON3 user manual

GMW

GMW TG uni 1 operating manual

Downeaster

Downeaster Wind & Weather Medallion Series instruction manual

Hanna Instruments

Hanna Instruments HI96725C instruction manual

Nokeval

Nokeval KMR260 quick guide

HOKUYO AUTOMATIC

HOKUYO AUTOMATIC UBG-05LN instruction manual

Fluke

Fluke 96000 Series Operator's manual

Test Products International

Test Products International SP565 user manual

General Sleep

General Sleep Zmachine Insight+ DT-200 Service manual