2

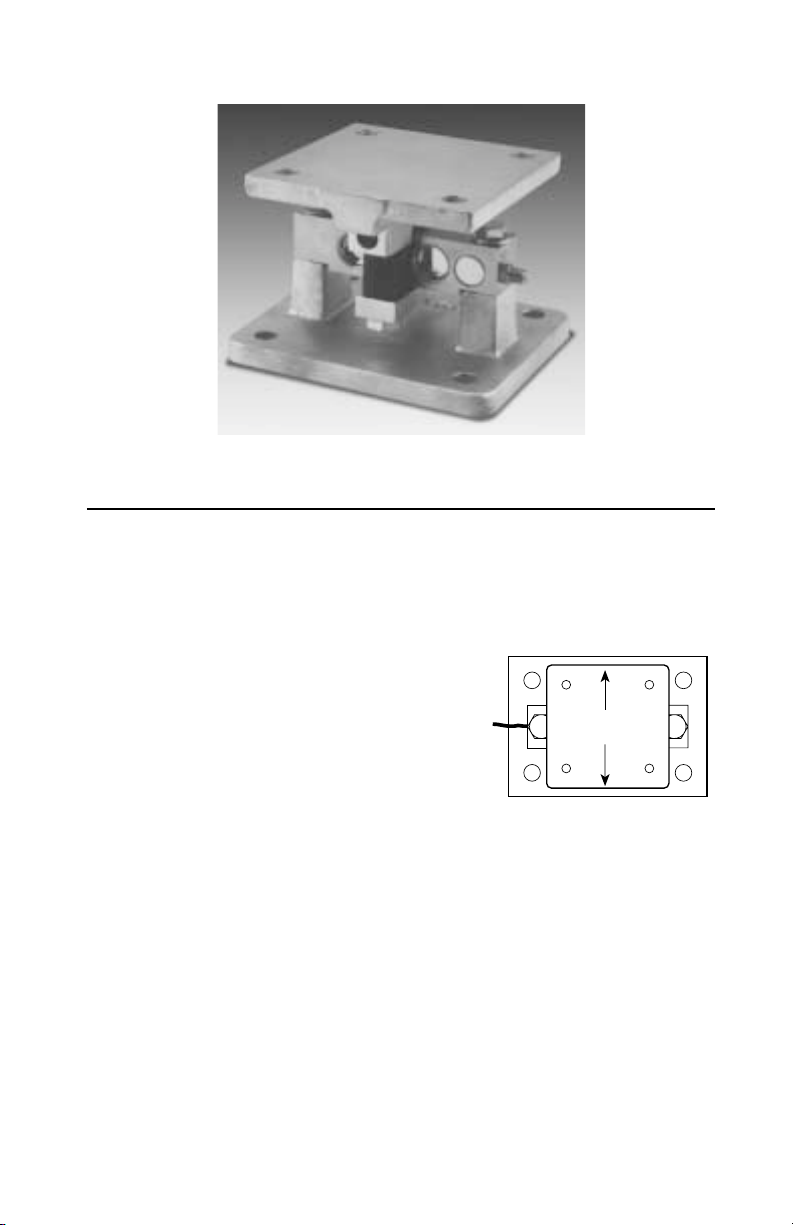

2.0 Mechanical Installation

2.1 General Installation Guidelines for Tank Mounts

1. Themountingsurfaceforthebaseandtopplatemustbelevel.Afterinstallation,

the top and bottom plates must be level within ±0.5°. If the mounting surfaces

are not level, then shims and/or grout may be used to level the mount.

Ifpossible,checkthatthemountislevelwhenthevesselisfullyloadedbecause

excessive deflections in legs and supporting structures may cause additional

sideforceswhichgreatlyaffectaccuracy.Deflectionofthemount’stoporbase

plate due to loading should not exceed ±.5°. Reinforcement of legs or other

support structures may be necessary to correct this. Vessels with long legs

should have cross bracing applied between adjacent legs to keep them from

spreading under load.

2. Compression mounting systems use three, four, or more mounts. More than

eight-module systems should be avoided as even weight distribution becomes

extremely difficult to achieve. The load on each mount assembly should vary

by no more than 20%. During installation, add shims where necessary to

achieve correct load distribution.

3. If the actual load cells are used during installation of the weighing assembly,

extreme care must be taken to prevent overload damage. A tank or hopper

weighingseveraltonscanexerthugeforces whendroppedonlyafractionofan

inch. Dummy load cells can be used during installation.

4. Itiscrucialthatallpipingorconduitbehorizontaland

flexible. If flexible piping is not used, make sure the

distancefromthe vesseltothe firstpipesupport is20-

30timesthe pipediameter.Fordetails, seethetechni-

cal information section of the RLWS Load Cell Prod-

uct Selection Guide. In smaller, lower capacity tanks

and hoppers, isolating the resultant forces becomes

extremely critical.

5. Load cells should not be installed in the mounts until all welding is completed.

The heat generated from welding current passing through a load cell can

damage the adhesive holding the strain gauge to the body. If possible, use a

dummy load cell when welding to maintain finished height. If welding is

unavoidable after load cell installation, connect the ground in such a way that

the current does not flow through the load cell. For example, if welding on the

mount top plate, the ground must be connected to the vessel, not to the mount

base or support structure. Also, protect the load cell and cable from weld

splatter.

Note: The arrow on the load cell should point in the direction of the load.

6. All support points should be equally stiff so that they deflect by the same

amount as the vessel is loaded.

LEVEL±0.5°

FLEXIBLE PIPING

J-BOX