Technical Bulletin PAGE: 1/5

Shepherd-P1

16-Oct-18

RJ093003

Subject: Changed the installation procedure for

installing the proximity sensors. Prepared by: Y.Kurohashi

1st System Business Promotion Section, System

Business Department

Troubleshooting

Mechanical

Paper path

Product Safety

Part information

Electrical

Transmit/receive

Other ( )

Action required

Service manual revision

Retrofit information

Tier 2

Service Manual Revision

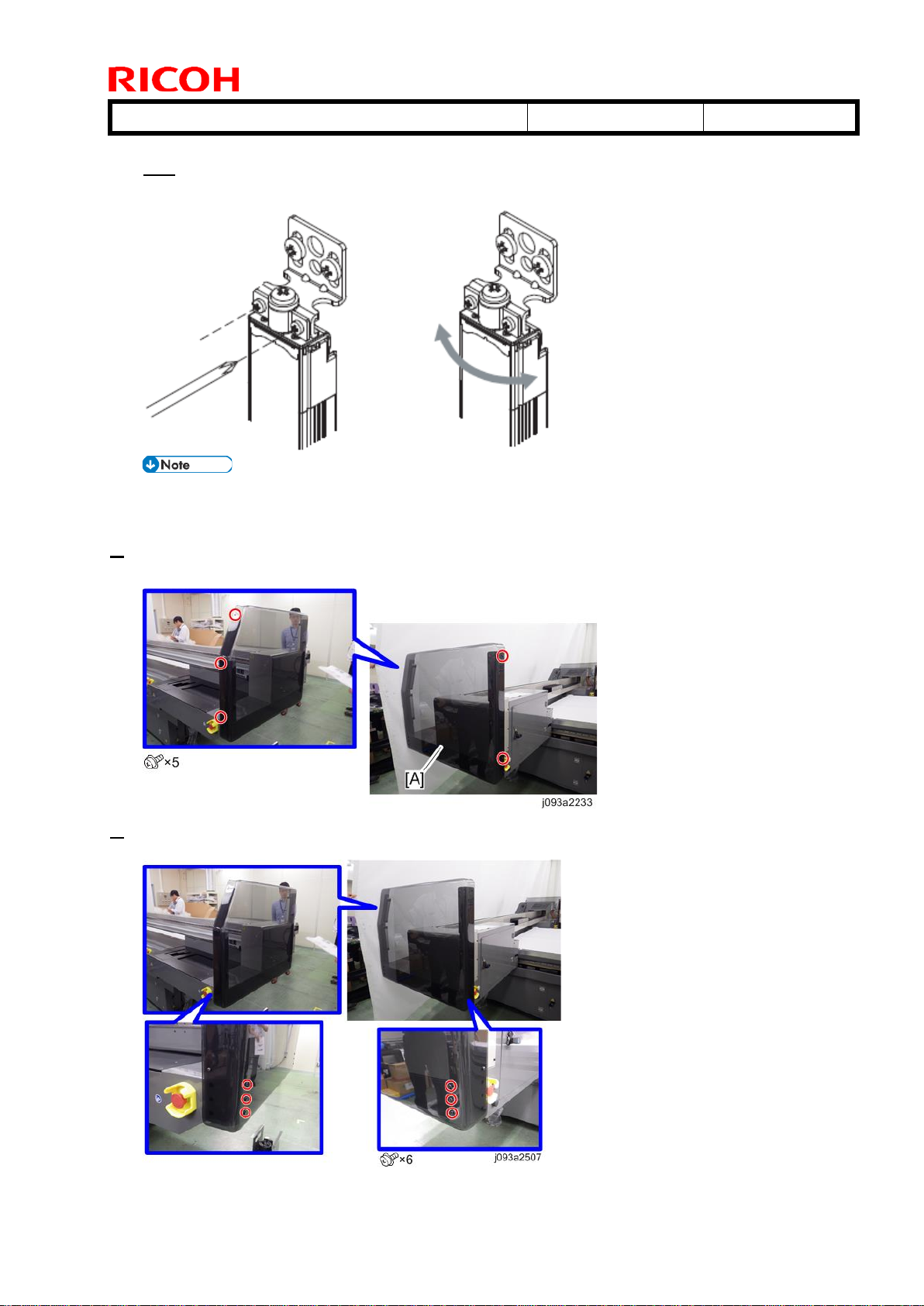

[2. Installation] - [Installing the Proximity Sensors]

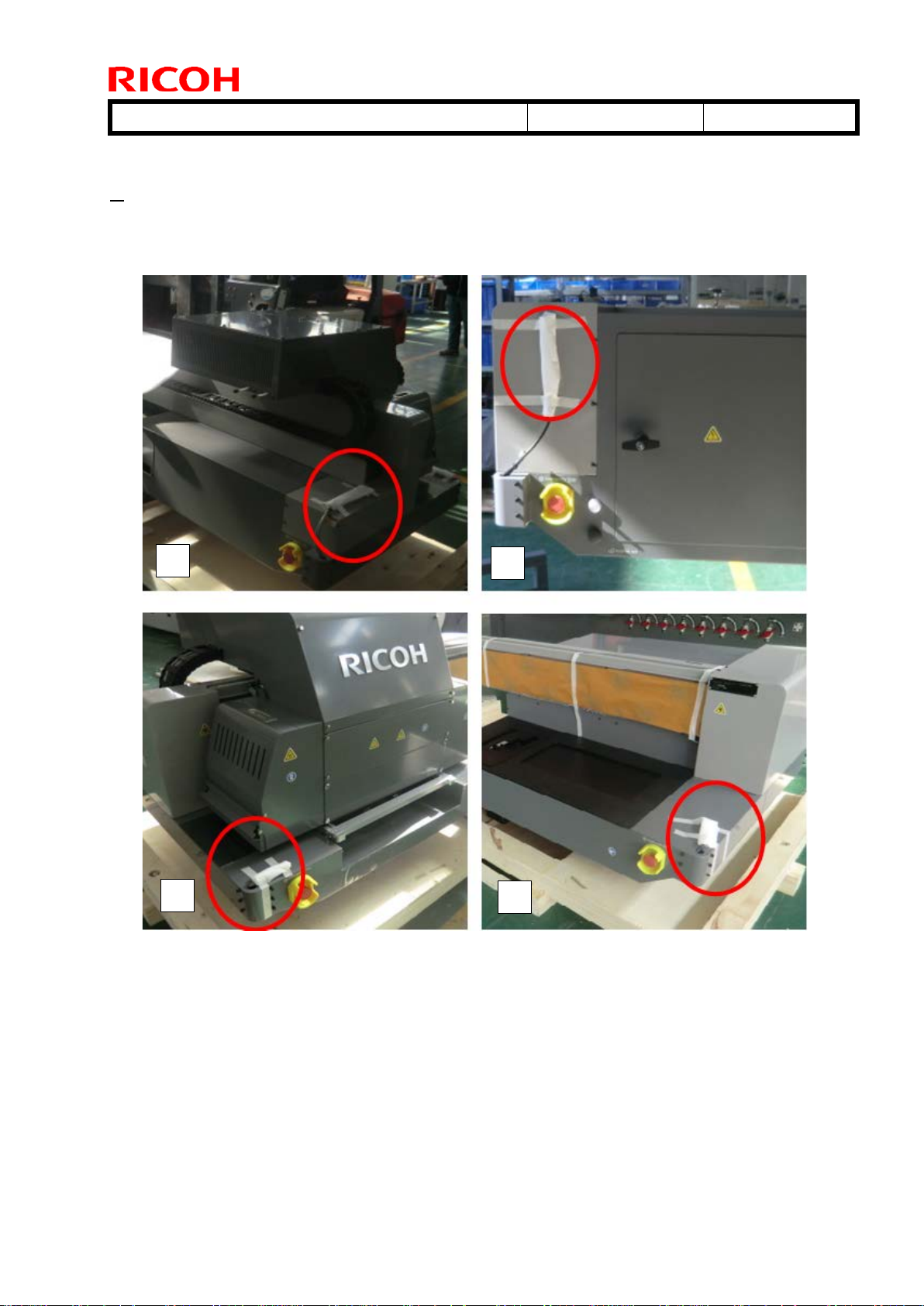

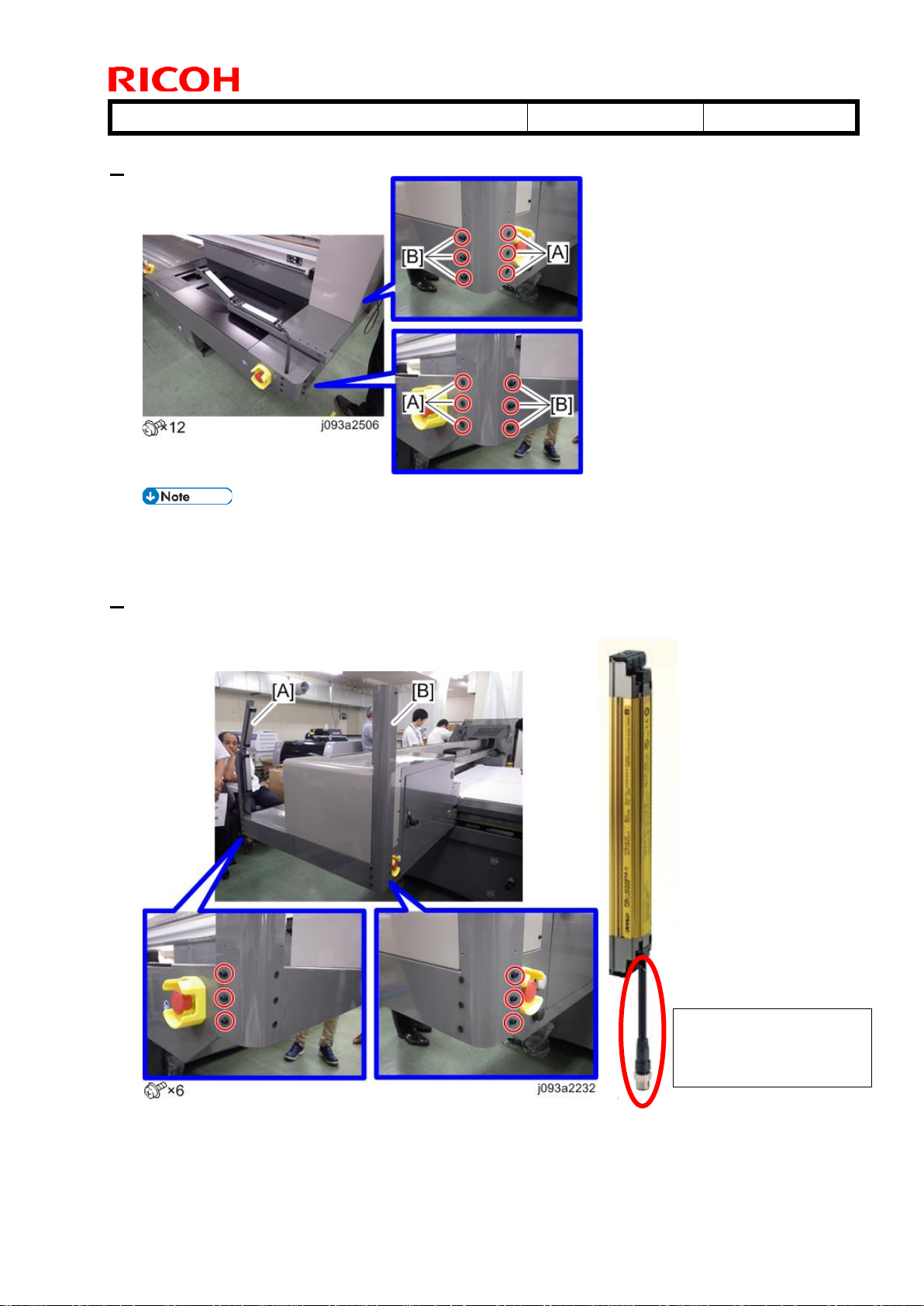

Changed the installation procedure for installing the proximity sensors.

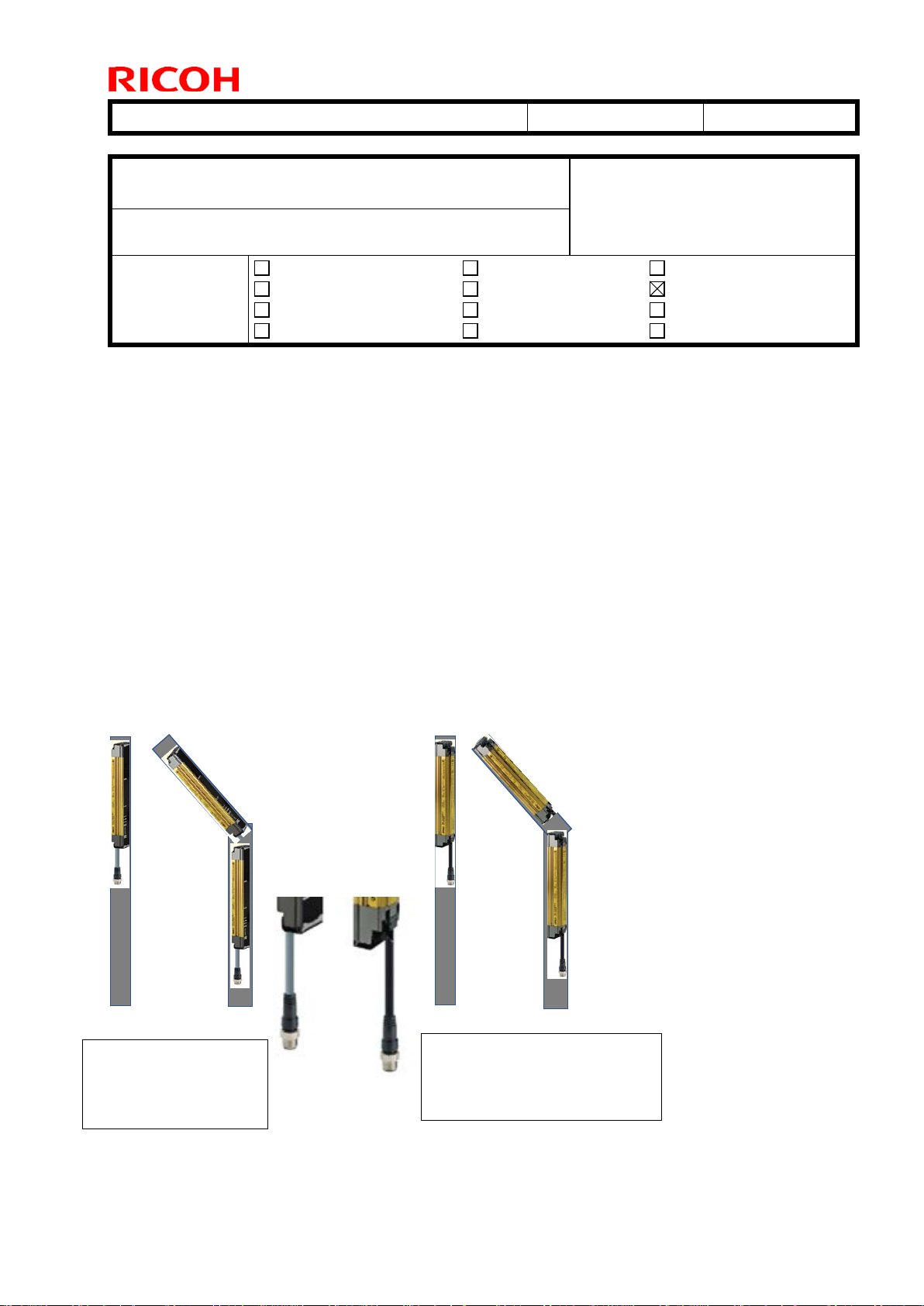

1) Proximity Sensors have been changed as Accessories.

2) According to 1), installing procedure has been changed.

3) It requires Adjustment of light receiving amount after assembling the sensors.

The items in italics were corrected or added.

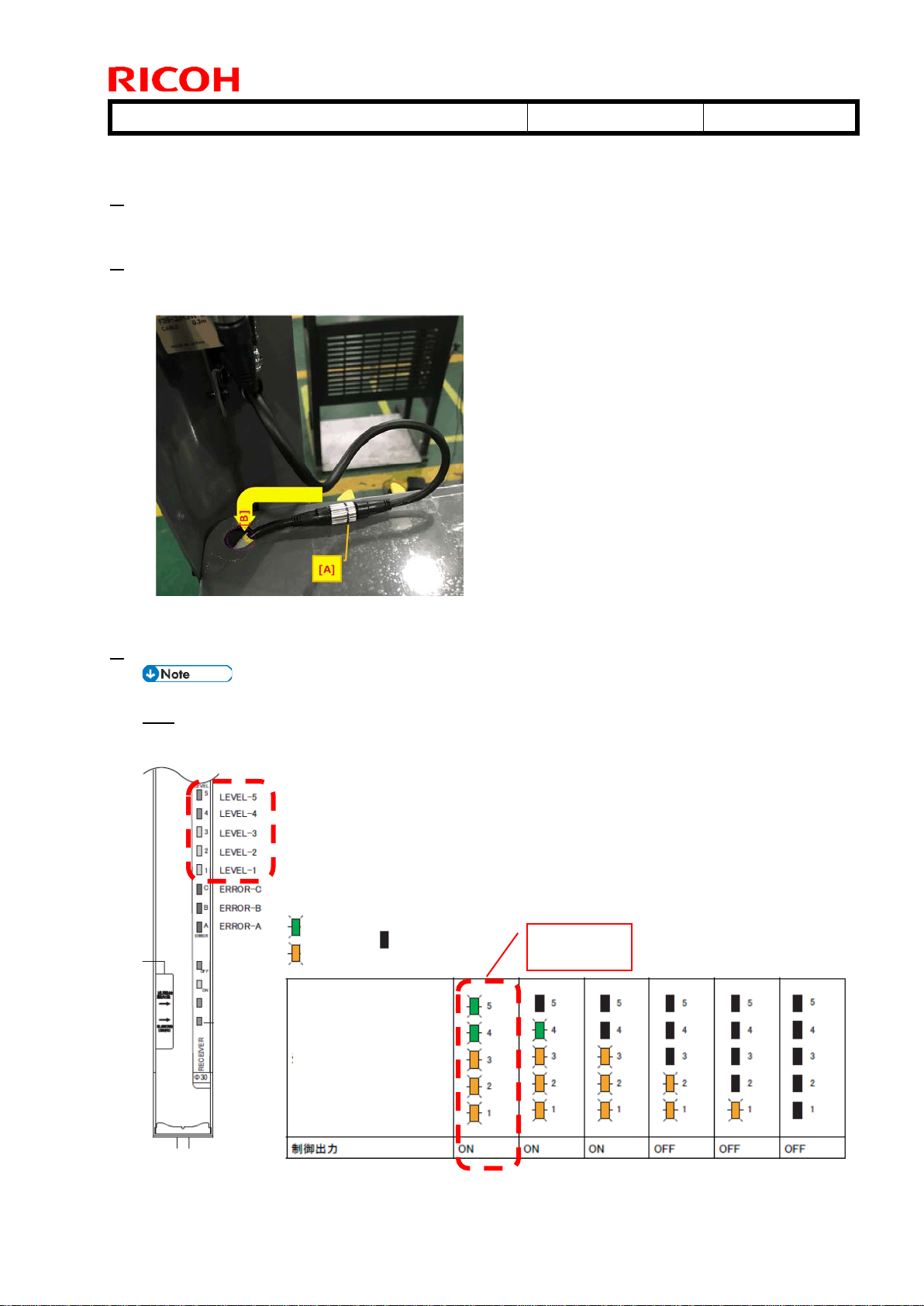

Procedure

Additional accessories

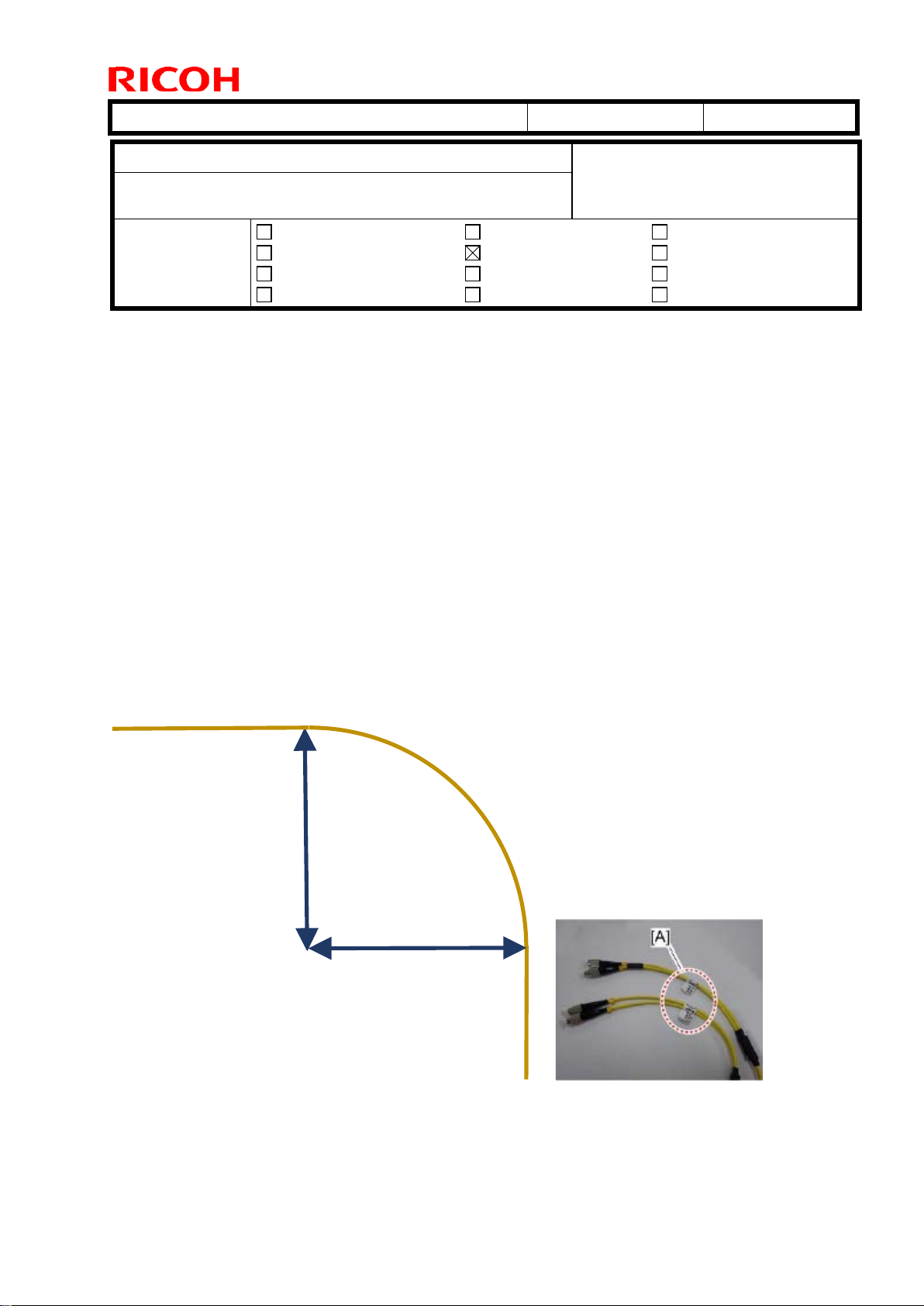

[For Left Rear], [For Left Front], [For Right Rear], [For Right Front]

:

: Black Cable

: Gray Cable